Iron ion reinforced anaerobic ammonia oxidation denitrification process

A technology of anaerobic ammonium oxidation and iron ions, which is applied in aerobic and anaerobic process treatment, anaerobic digestion treatment, chemical instruments and methods, etc., can solve the problems of anaerobic ammonium oxidation denitrification efficiency, poor process stability, Slow enrichment culture and other problems, to achieve the effect of accelerating enrichment culture, improving process stability, and promoting microbial growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

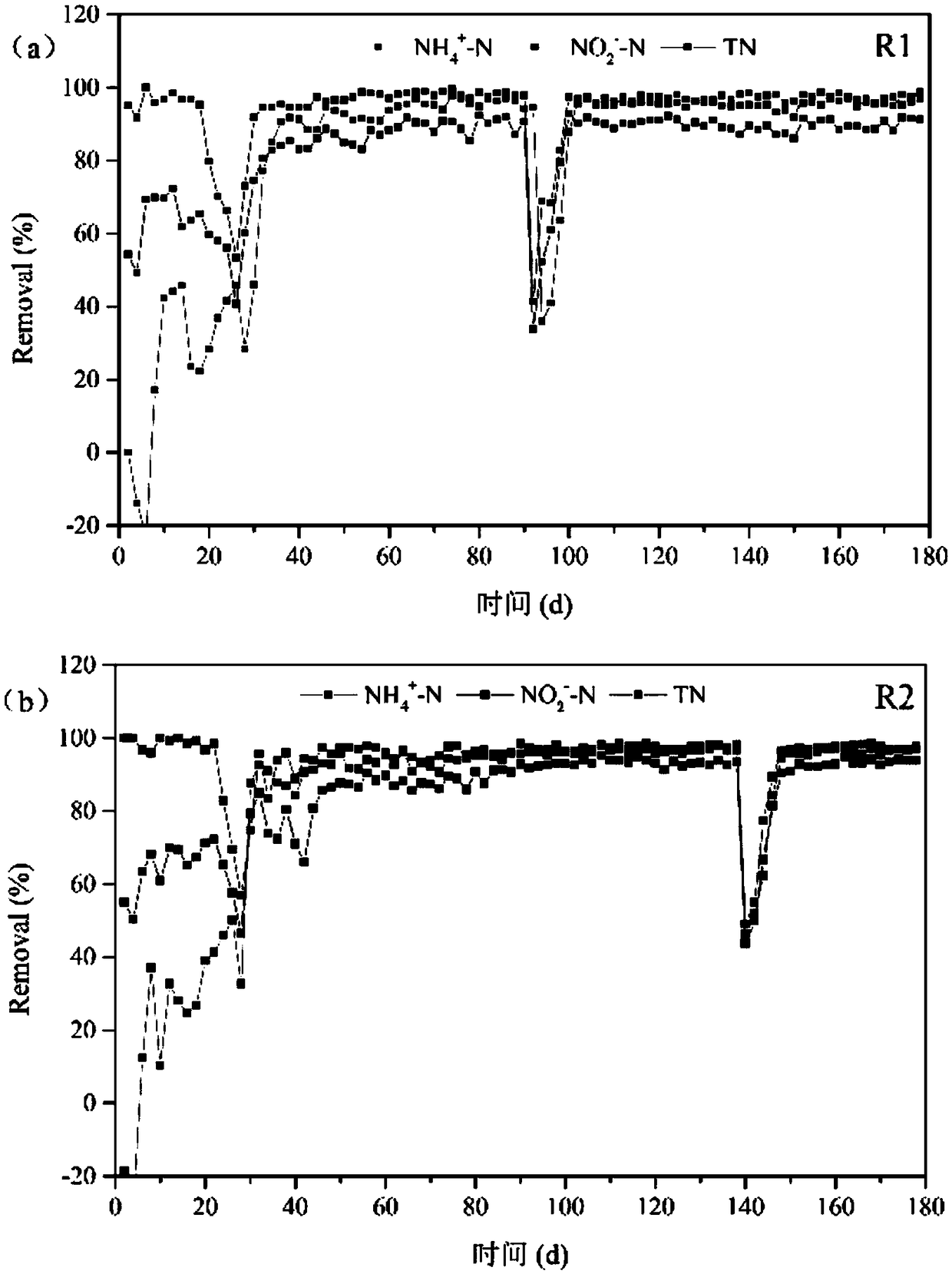

Image

Examples

Embodiment 1

[0040] An iron ion enhanced anammox denitrification process, the specific steps of the anammox denitrification process are as follows:

[0041] Step 1: first add 1.25mL / L trace element concentrate in the waste water to be treated, then select the acid solution of mass concentration 30% to adjust the waste water to be treated so that the pH is 6.7, the acid solution under this concentration can slightly adjust the pH, Avoid inaccurate pH adjustments. Finally, aerate with high-purity nitrogen with a concentration greater than 99.5% until the dissolved oxygen is lower than 0.5 mg / L to obtain treated wastewater, and the aeration time is 2 hours;

[0042] Step 2: Sludge selects denitrification sludge for use, uses the K of pH=7.2 2 HPO 4 / KH 2 PO 4 The buffer solution washes the denitrification sludge multiple times to wash away the ammonia nitrogen, organic matter, nitrite and nitrate in the denitrification sludge, and adds the sludge into the anammox reactor;

[0043] Step 3...

Embodiment 2

[0051]An iron ion enhanced anammox denitrification process, the specific steps of the anammox denitrification process are as follows:

[0052] Step 1: first add 1.25mL / L trace element concentrated solution in the waste water to be treated, then select the acid solution of mass concentration 35% to adjust the waste water to be treated so that the pH is 6.7, the acid solution under this concentration can slightly adjust the pH, Avoid inaccurate pH adjustments. Finally, aerate the treated wastewater with high-purity nitrogen with a concentration greater than 99.5% until the dissolved oxygen is lower than 0.5 mg / L, and the aeration time is 2.5 hours;

[0053] Step 2: Sludge selects denitrification sludge for use, uses the K of pH=7.2 2 HPO 4 / KH 2 PO 4 The buffer solution washes the denitrification sludge multiple times to wash away the ammonia nitrogen, organic matter, nitrite and nitrate in the denitrification sludge, and adds the sludge into the anammox reactor;

[0054] S...

Embodiment 3

[0062] An iron ion enhanced anammox denitrification process, the specific steps of the anammox denitrification process are as follows:

[0063] Step 1: first add 1.25mL / L trace element concentrate in the waste water to be treated, then select the acid solution of mass concentration 38% to adjust the waste water to be treated so that the pH is 6.8, the acid solution under this concentration can slightly adjust the pH, Avoid inaccurate pH adjustments. Finally, aerate with high-purity nitrogen with a concentration greater than 99.5% until the dissolved oxygen is lower than 0.5mg / L to obtain treated wastewater, and the aeration time is 3 hours;

[0064] Step 2: Sludge selects denitrification sludge for use, uses the K of pH=7.2 2 HPO 4 / KH 2 PO 4 The buffer solution washes the denitrification sludge multiple times to wash away the ammonia nitrogen, organic matter, nitrite and nitrate in the denitrification sludge, and adds the sludge into the anammox reactor;

[0065] Step 3:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com