Preparation method of tantalum powder

A kind of technology of tantalum powder and pulverizing equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

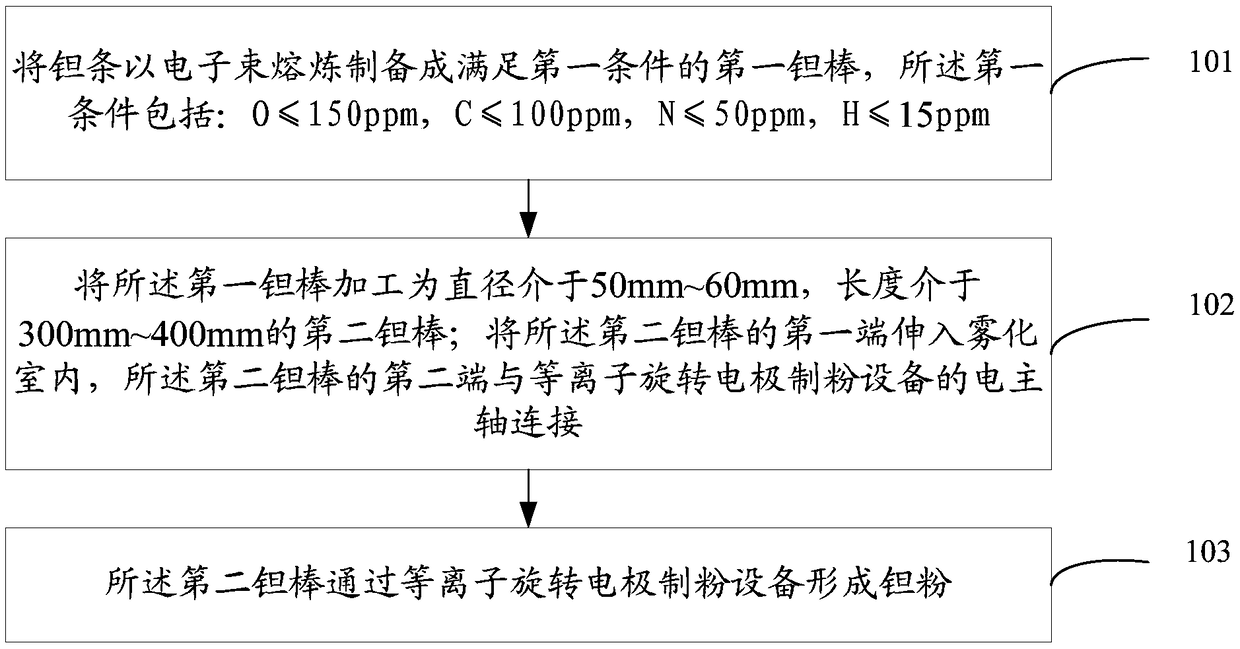

[0021] figure 1 A schematic flow chart of a preparation method for tantalum powder proposed in an embodiment of the present invention, as figure 1 As shown, the method mainly includes the following steps:

[0022] In step 101, the tantalum rod is prepared by electron beam melting into a first tantalum rod satisfying the first condition, the first condition includes: O≤150ppm, C≤100ppm, N≤50ppm, H≤15ppm;

[0023] Step 102, processing the first tantalum rod into a second tantalum rod with a diameter ranging from 50 mm to 60 mm and a length ranging from 300 mm to 400 mm; extending the first end of the second tantalum rod into the atomization chamber, the The second end of the second tantalum rod is connected to the electric spindle of the plasma rotating electrode pulverizing equipment;

[0024] Step 103, the second tantalum rod is formed into tantalum powder through the plasma rotating electrode powder making equipment.

[0025] In step 101, the tantalum rod is prepared into ...

Embodiment 1

[0033] Step 1, smelting the tantalum rod into a high-purity first tantalum rod by an electron beam melting process;

[0034] O=130ppm, C=90ppm, N=30ppm, H=12ppm in the first tantalum rod.

[0035] Step 2: Machining the first tantalum rod to a second tantalum rod with a diameter of 50 mm and a length of 300 mm;

[0036] Step 3. Connect the second end of the second pure tantalum rod to the electric spindle, and extend the first end into the argon-protected spray chamber, and drive the tantalum rod to rotate at high speed in the horizontal direction with the electric spindle;

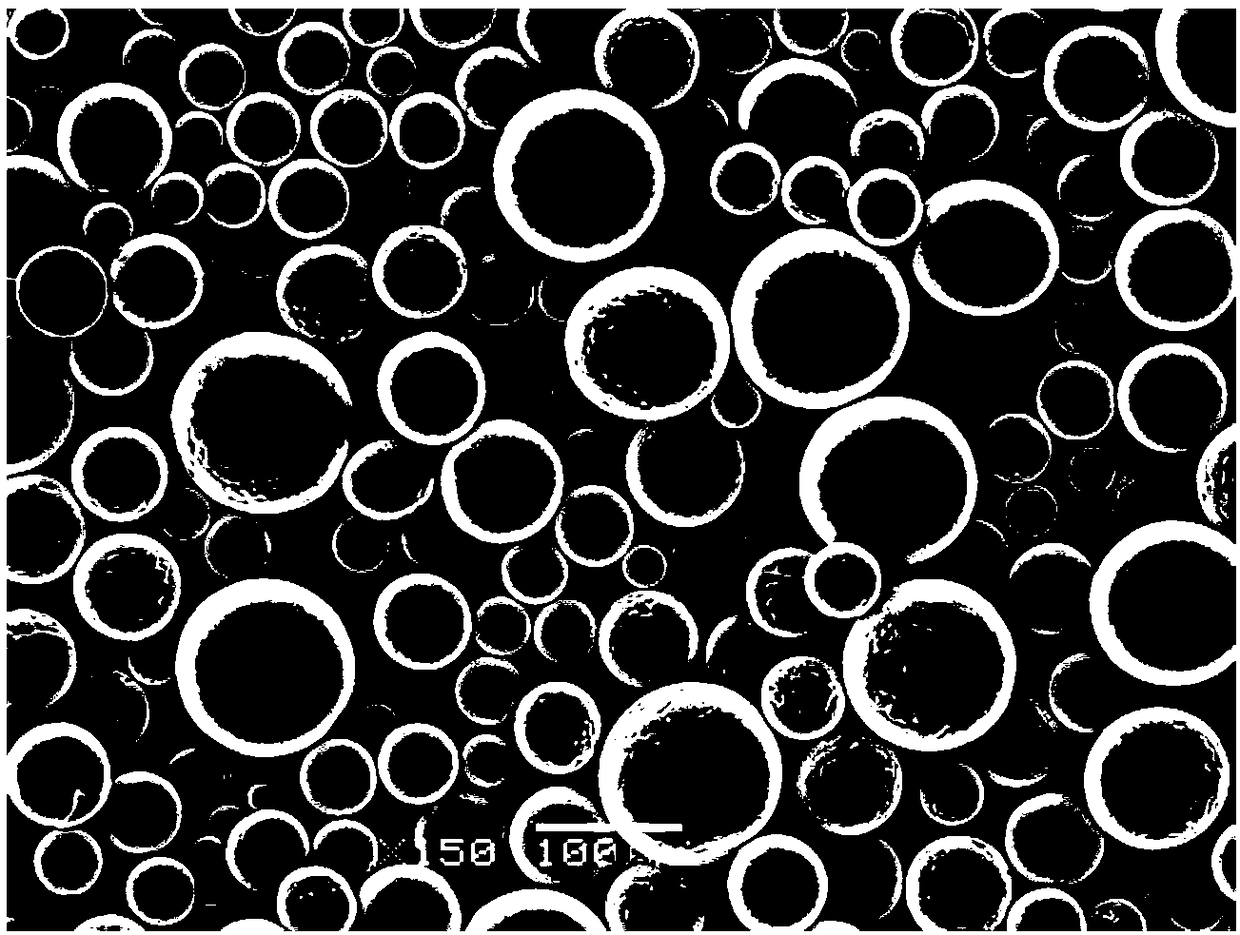

[0037] Step 4: Use a high-power plasma arc with a melting current of 4000A to melt the second tantalum rod rotating at high speed. The first end surface of the second tantalum rod is melted and centrifugally dispersed and condensed to obtain tantalum powder with high sphericity.

[0038] The diameter of the first tantalum rod in step 1 is 60 mm, the length of the first end of the second tantalum rod exten...

Embodiment 2

[0041] Step 1, smelting the tantalum rod into a high-purity first tantalum rod by an electron beam melting process;

[0042] O=130ppm, C=90ppm, N=30ppm, H=12ppm in the first tantalum rod.

[0043] Step 2: Machining the first tantalum rod to a second tantalum rod with a diameter of 60 mm and a length of 400 mm;

[0044] Step 3. Connect the second end of the second pure tantalum rod to the electric spindle, and extend the first end into the argon-protected spray chamber, and drive the second tantalum rod to rotate at high speed in the horizontal direction with the electric spindle;

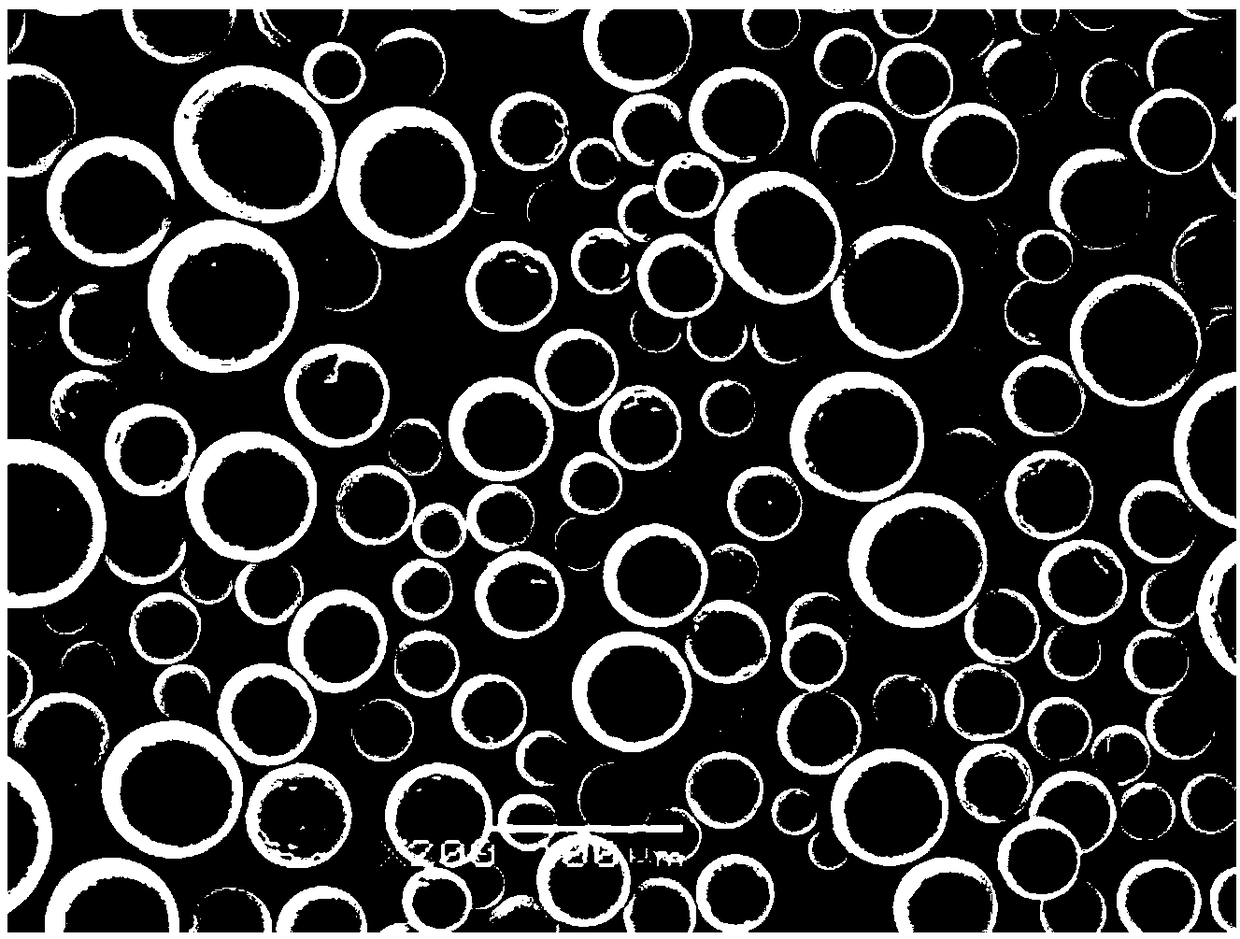

[0045] Step 4: Melt and rotate the second tantalum rod at a high speed with a high-power plasma arc with a melting current of 5000A. The first end surface of the second tantalum rod is melted, centrifugally dispersed, and condensed to obtain tantalum powder with high sphericity.

[0046] The diameter of the first tantalum rod in step 1 is 70 mm, the length of the first end of the second tantalum rod ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com