Preparation method of molybdenum disulfide composite material

A composite material, molybdenum disulfide technology, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, chemical/physical processes, etc., to achieve simple and fast preparation methods, improve the ability to capture light, and prepare cost-effective method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

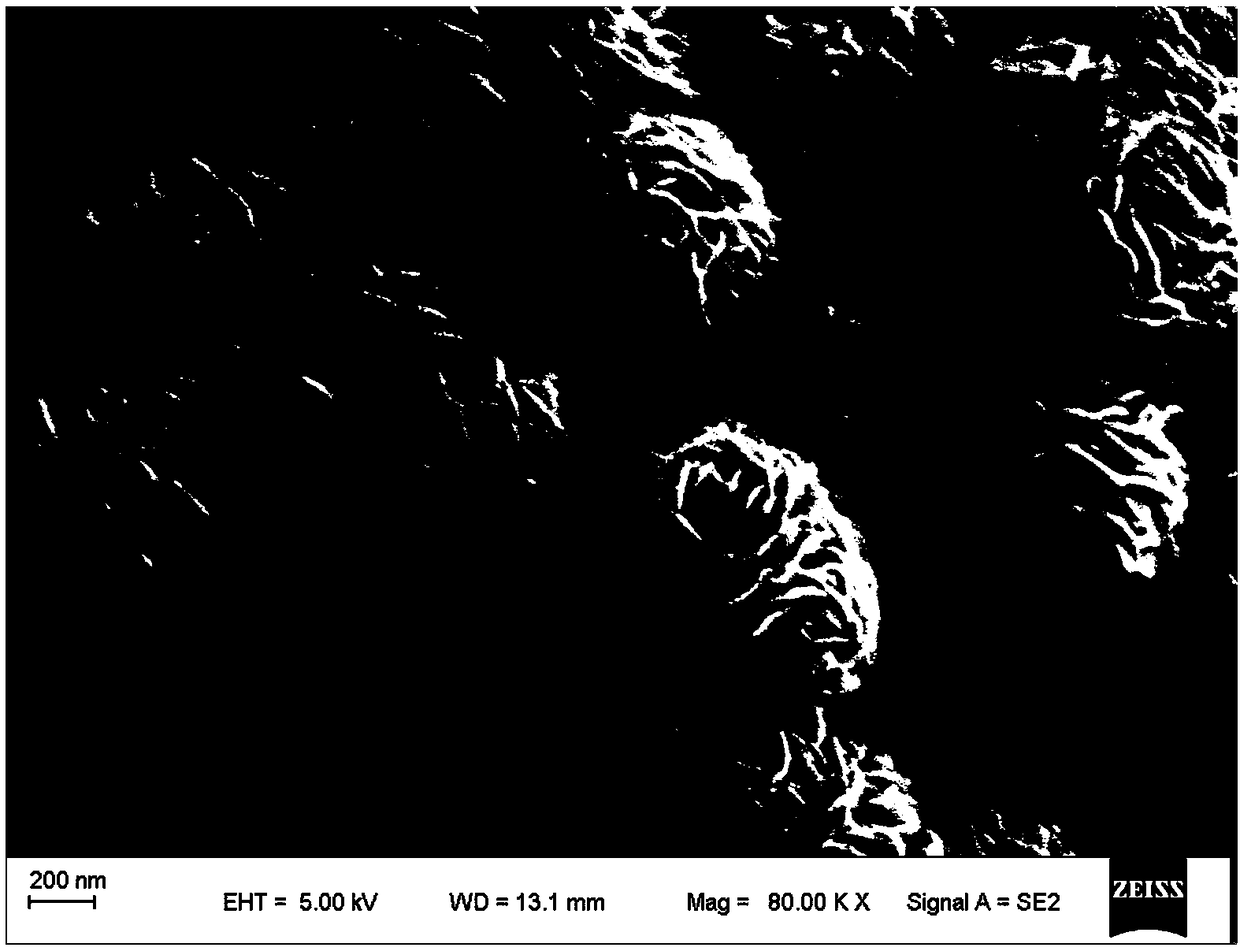

[0030] Weigh 80mg of sodium molybdate and 320mg of thioacetamide, dissolve them in 64mL of deionized water, stir at room temperature for 30 minutes to make them fully dissolve, and then transfer them to a 100mL reactor with a polytetrafluoroethylene liner. React at 200°C for 24 hours. After the reaction is over, cool the reactor to room temperature, pour off the supernatant, and leave a black turbid solution. Use ethanol and deionized water to ultrasonically clean several times, then centrifuge, and finally Under vacuum drying at ℃ for 12 hours, the obtained black powder is petal-shaped molybdenum disulfide, and the field emission scanning electron microscope picture is as follows: figure 1 shown.

Embodiment 2

[0032] Weigh 80mg of sodium molybdate and 320mg of thioacetamide, dissolve them in 64mL of deionized water, stir at room temperature for 30 minutes to make them fully dissolve, and then transfer them to a 100mL reactor with a polytetrafluoroethylene liner. React at 180°C for 24 hours. After the reaction is over, cool the reactor to room temperature, pour off the supernatant, and leave a black turbid solution. Use ethanol and deionized water to ultrasonically clean several times, then centrifuge, and finally After vacuum drying at ℃ for 12 hours, the obtained black powder is petal-shaped molybdenum disulfide.

Embodiment 3

[0034] Weigh 80mg of sodium molybdate and 160mg of thioacetamide, dissolve them in 64mL of deionized water, stir at room temperature for 30 minutes to fully dissolve them, and then transfer them to a 100mL reaction kettle with a polytetrafluoroethylene liner. React at 180°C for 24 hours. After the reaction is over, cool the reactor to room temperature, pour off the supernatant, and leave a black turbid solution. Use ethanol and deionized water to ultrasonically clean several times, then centrifuge, and finally After vacuum drying at ℃ for 12 hours, the obtained black powder is petal-shaped molybdenum disulfide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com