Online monitoring method for energy efficiency of spindle system during service process of numerically controlled machine tool

A CNC machine tool and energy efficiency technology, applied in general control systems, control/regulation systems, program control, etc., can solve problems such as online monitoring of machine tool energy efficiency, achieve good engineering application value, broad application prospects, and simple and easy operation. row effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

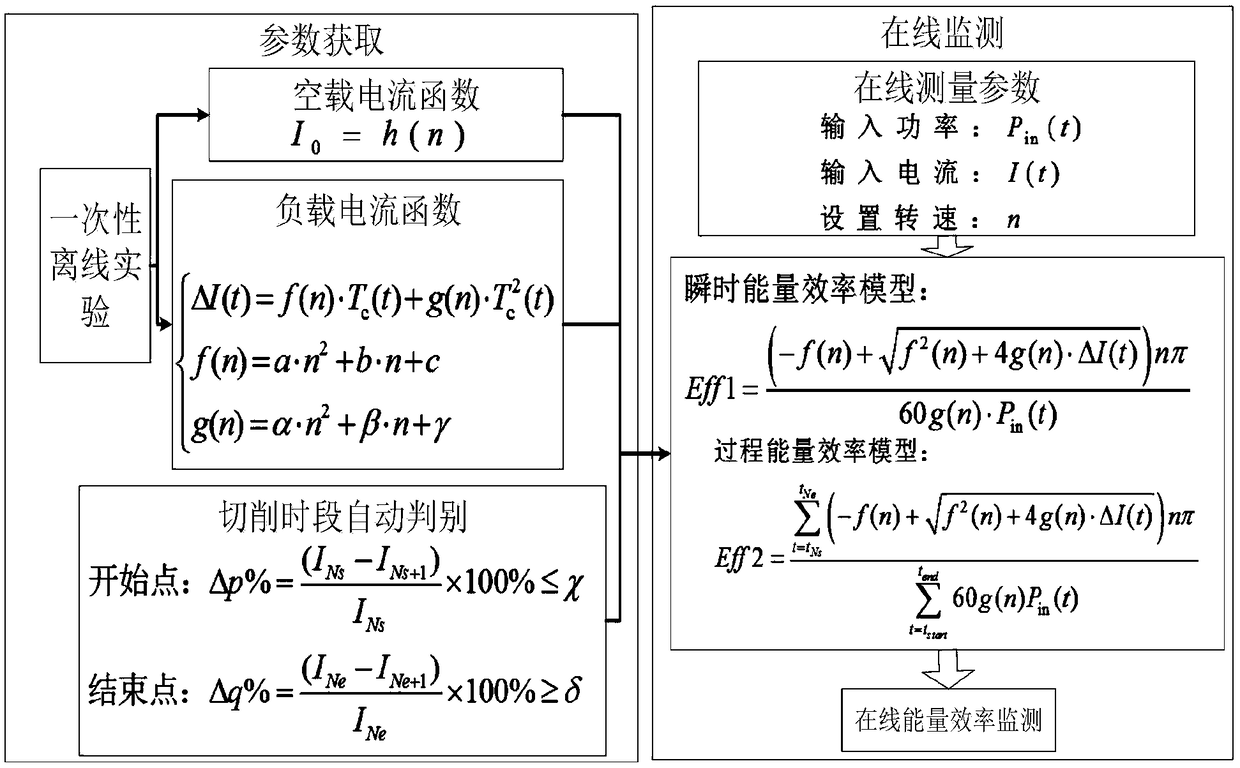

Method used

Image

Examples

Embodiment

[0054] Since the online monitoring method of the instantaneous energy efficiency of the spindle system of the CNC machine tool in service needs to collect the input power and cutting power at the same time in real time, it is difficult to achieve complete synchronous collection during verification, so it is inconvenient to verify here. Therefore, the following mainly verifies the monitoring accuracy of process energy efficiency.

[0055] This embodiment monitors the instantaneous energy efficiency of the spindle system of the C2-6136HK / 1 CNC lathe during its service. In the experiment, the Hichi 3390 power analyzer was installed at the input point of the spindle system to measure the three-phase input current and input power of the spindle system; the KISTLER 9257B was installed on the pallet to measure the cutting torque during the cutting process. The process is as follows:

[0056] 1) Acquisition of machine tool characteristic model

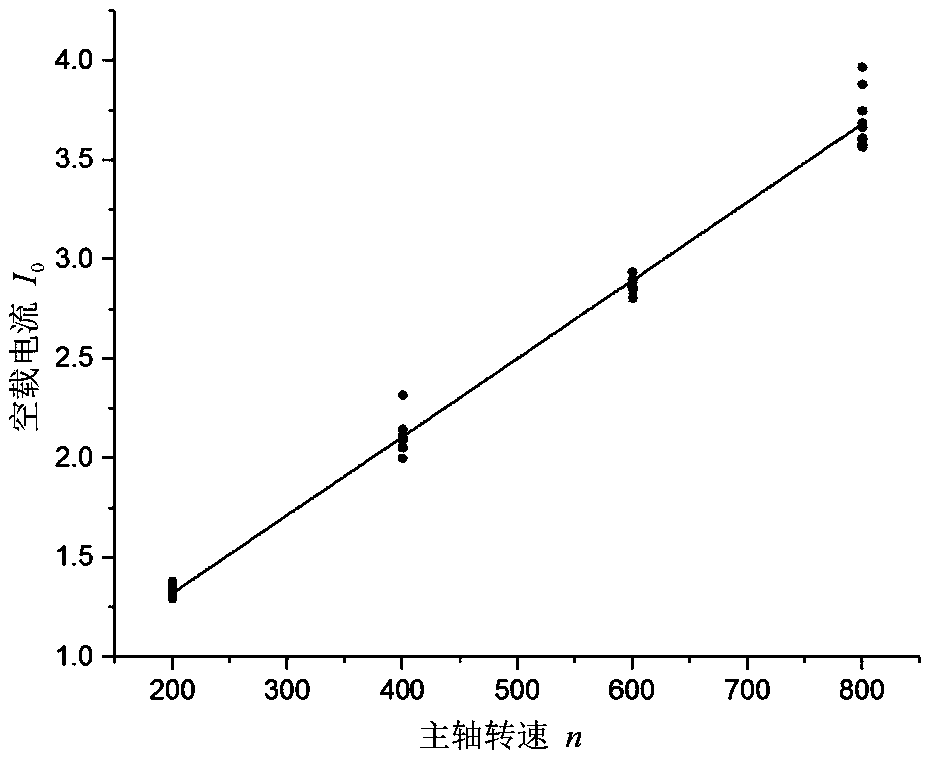

[0057] a. No-load current model const...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com