Potassium permanganate consumption standard sample for plastic products for food contact and preparation method

A standard sample, potassium permanganate technology, applied in the field of formula and preparation of standard samples, can solve the problems of large differences in test results, troubled by the detection standard of potassium permanganate consumption, etc., and achieve good uniformity and stability , the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

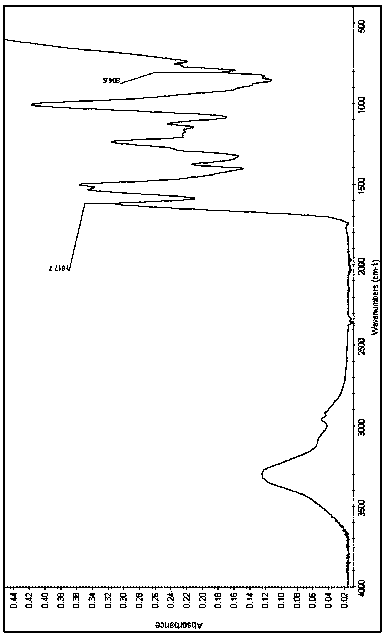

Image

Examples

Embodiment Construction

[0028] The standard sample of potassium permanganate consumption of plastic products for food contact is mainly made of the following raw materials in parts by weight:

[0029] Amino molding compound 63~73 parts

[0030] α wood pulp fiber 17~27 parts

[0031] Calcium carbonate 2.5~4.5 parts

[0032] Barium sulfate 1.5~3.0 parts

[0033] Titanium dioxide 0.5~1.5 parts

[0034] Curing agent ammonium sulfamate 0.25~0.35 parts

[0035] Flow agent polyethylene wax 0.3~1.0 parts

[0036] Lubricant zinc stearate 0.4~0.6 parts

[0037] Surfactant sodium lauryl sulfate 1.0~3.0 parts

[0038] At the same time, the preparation method of the standard sample of potassium permanganate consumption of food contact plastic products composed of the above raw materials mainly adopts the following steps:

[0039] ① Accurately weigh each raw material according to the stated parts by weight, and combine the weighed amino molding compound with α wood pulp fiber, calcium carbonate, barium sulf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com