Bismuth vanadate composite materials loaded with magnetic nanoparticles and preparation and application thereof

A technology of magnetic nanoparticles and composite materials, applied in the field of BiVO4-based composite materials, can solve the problems of low carrier transport rate and affecting photocatalytic reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

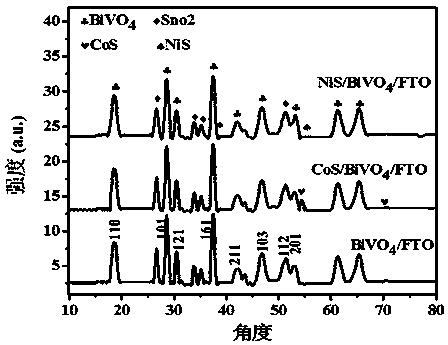

[0036] Embodiment 1, NiS / BiVO The preparation of composite material

[0037] (1) Preparation of BiOI thin film

[0038] BiOI thin films were prepared by electrodeposition by cyclic voltammetry in a three-electrode system. The three electrodes are: platinum sheet as the counter electrode, Ag / AgCl electrode as the reference electrode, and FTO conductive glass as the working electrode (clean with isopropanol, acetone, absolute ethanol, and double distilled water in sequence before use). Electrodeposition conditions: the potential window is 0V~-0.13V, the scan rate is 5mV / s, the number of scan cycles is 10, and the electrodeposition is carried out at room temperature. After electrodeposition was completed, it was rinsed with double distilled water and dried at 60 °C. The electrolyte solution for preparation of BiOI thin films by electrodeposition is prepared as follows:

[0039] a. Weigh 3-3.5g of potassium iodide (KI) into a dry and clean beaker, add 40-60 mL of double distill...

Embodiment 2

[0051] Example 2, CoS / BiVO 4 Preparation of composite materials

[0052] (1) Preparation of BiOI thin film: same as Example 1;

[0053] (2) BiVO 4 The preparation of thin film: with embodiment 1;

[0054] (3) Preparation of CoS: Co(NO 3 ) 2 ·7H 2 O (7.3g, 0.025mol) and thiourea (5.45g, 0.06mol) were mixed in 80mL ethylene glycol solution, stirred evenly, put into a stainless steel autoclave lined with polytetrafluoroethylene, and the reaction temperature was controlled at React at 140°C~160°C for 15~16 hours; the reaction product was centrifuged and washed three times with ethanol and deionized water respectively, and then kept dry at 80°C for 10~12 hours. The obtained sample was ground to obtain 1.8g of nano-CoS powder.

[0055] (4) CoS / BiVO 4 Composite material: Add nano-CoS powder into 2.5mL ethanol solution, and ultrasonically disperse for 30-40 minutes to obtain a suspension; use a pipette gun to draw a small amount (100 μL) of CoS ethanol solution, and add it drop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com