Method of achieving electric conduction on high-temperature rubber by using vapor deposition graphene

A vapor deposition and graphene technology, applied in the direction of coating, etc., can solve the problems of high cost, shortening the service life of rubber, difficult to control, etc., and achieve the effect of improving anti-corrosion ability, improving mechanical properties, and overcoming weak contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

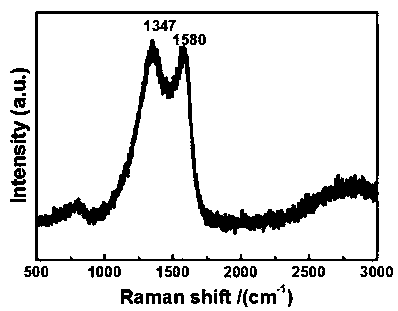

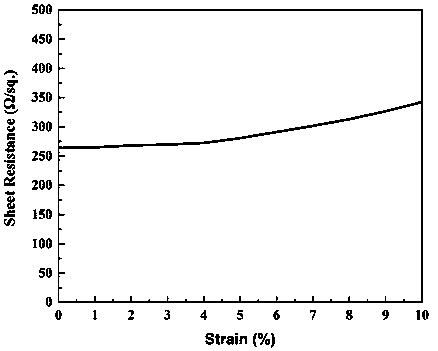

Image

Examples

Embodiment 1

[0044] Embodiment 1, vapor deposition graphene to realize the acrylate rubber conduction method of butyl acrylate main monomer doped nano-Cu flakes and nano-GaIn particles

[0045] 1. The preparation of the acrylate rubber substrate of butyl acrylate main monomer doped nano-Cu flakes and GaIn alloy nanoparticles comprises the following steps:

[0046] (1) Purify butyl acrylate in a rotary evaporator, remove the polymerization inhibitor and other impurities, put it in the refrigerator and keep it for later use;

[0047] (2) The main monomer butyl acrylate obtained in (1), the vulcanization point monomer glycidyl methacrylate, nano-Cu flakes, GaIn alloy nanoparticles (the atomic ratio of Ga to In is 1:10), solvent Mix ethyl acetate to form a monomer mixed solution;

[0048] (3) Add the monomer mixed solution obtained in (2) into a 2L glass reactor for magnetic stirring, turn on the stirring paddle and set the rotation speed to 200r / min, and inject nitrogen to empty the air in t...

Embodiment 2

[0057] Embodiment 2, vapor deposition graphene to realize the acrylate rubber conduction method of butyl acrylate main monomer doped nano-Ni sheets composite GaIn alloy nanoparticles

[0058] 1. The preparation of butyl acrylate main monomer doped nano-Ni sheet and nano-GaIn particle acrylate rubber substrate comprises the following steps:

[0059] (1) Purify butyl acrylate in a rotary evaporator, remove the polymerization inhibitor and other impurities, put it in the refrigerator and keep it for later use;

[0060] (2) The main monomer butyl acrylate obtained in (1), the vulcanization point monomer glycidyl methacrylate, nano-Ni flakes and GaIn alloy nanoparticles (the atomic ratio of Ga to In is 10:1), solvent Toluene is mixed to form a monomer mixed solution;

[0061] (3) Add the monomer mixed solution obtained in (2) into a 2L glass reactor for magnetic stirring, turn on the stirring paddle and set the rotation speed to 200r / min, and inject nitrogen to empty the air in th...

Embodiment 3

[0070] Embodiment 3, vapor phase deposition of graphene to realize the method of ethyl acrylate main monomer doping nano-Ni sheets composite GaIn alloy nanoparticles of acrylate rubber conduction

[0071] 1. The preparation of the acrylate rubber substrate of ethyl acrylate main monomer doped nano-Ni sheets and nano-GaIn particles comprises the following steps:

[0072] (1) Purify ethyl acrylate in a rotary evaporator, remove the polymerization inhibitor and other impurities, put it in the refrigerator and keep it for later use;

[0073] (2) The main monomer ethyl acrylate obtained in (1), the vulcanization point monomer glycidyl methacrylate, nano-Ni flakes and GaIn alloy nanoparticles (the atomic ratio of Ga to In is 1:1), solvent Mix ethyl acetate to form a monomer mixed solution;

[0074] (3) Add the monomer mixed solution obtained in (2) into a 2L glass reactor for magnetic stirring, turn on the stirring paddle and set the rotation speed to 200r / min, and inject nitrogen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com