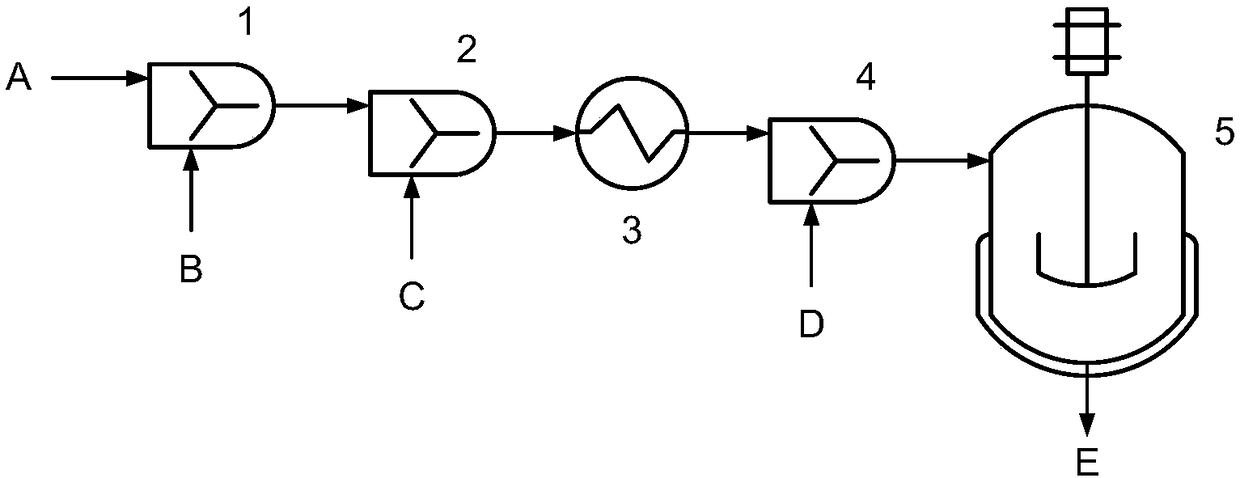

Micro-reaction method for continuous synthesis of thiuram disulfide

A technology of tetraalkyl disulfide and thiuram, applied in organic chemistry and other directions, can solve the problems of backward cleanliness and safety mixed acid oxidation process, difficult to suppress side reactions, low utilization rate of raw materials, etc. High product yield, process safety and environmental protection effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

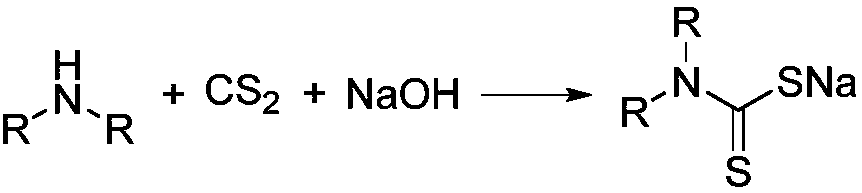

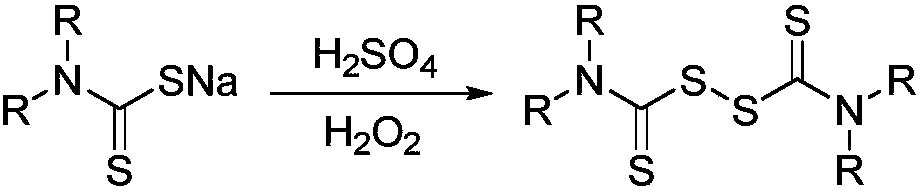

Method used

Image

Examples

Embodiment 1

[0022] Prepare a NaOH aqueous solution with a mass fraction of 15%, 10% H 2 o 2 Sulfuric acid solution, the use of mass fraction is 41% dimethylamine aqueous solution as raw material, control dimethylamine, CS 2 , NaOH, H 2 SO 4 、H 2 o 2 The molar ratio between is 1.0:1.0:1.1:0.55:0.55, at room temperature (26 ℃) enters micro-mesh dispersing mixer (aperture 200 μm, hole number 5) successively through metering pump, micro-mesh condensation reactor ( The pore size is 200 μm, the number of holes is 10) and the micro-sieve oxidation reactor (the size of the hole is 500 μm, the number of holes is 10), and the discharge temperature of the intermediate heat exchanger is controlled by circulating water to 10 ° C. The product is collected in a 500mL stirred tank, filtered, washed and dried Finally, tetramethylthiuram disulfide with a purity of 98.1% was obtained, and the solid yield was 100%.

Embodiment 2

[0024] Prepare a NaOH aqueous solution with a mass fraction of 15%, 5% H 2 o 2 Sulfuric acid solution, the use of mass fraction is 41% dimethylamine aqueous solution as raw material, control dimethylamine, CS 2 , NaOH, H 2 SO 4 、H 2 o 2 The molar ratio between them is 1.0:1.0:1.0:0.5:0.5, and at room temperature (26°C) enters the micro-sieve dispersion mixer (aperture 800 μm, hole number 1) successively through the metering pump, and the micro-sieve condensation reactor ( Aperture 800μm, hole number 1) and micro-sieve oxidation reactor (pore size 800μm, hole number 2), through circulating water to control the discharge temperature of the intermediate heat exchanger to 10°C, collect the product in a 500mL stirred tank, filter, wash and dry Finally, tetramethylthiuram disulfide with a purity of 97.4% was obtained, and the solid yield was 99%.

Embodiment 3

[0026] Prepare a NaOH aqueous solution with a mass fraction of 15%, 5% H 2 o 2 Sulfuric acid solution, the use of mass fraction is 41% dimethylamine aqueous solution as raw material, control dimethylamine, CS 2 , NaOH, H 2 SO 4 、H 2 o2 The molar ratio between them is 1.0:1.0:1.05:0.52:0.55. At room temperature (28°C), they enter the T-shaped microchannel mixer (hydraulic diameter 300 μm, channel number 4) sequentially through the metering pump, and the T-shaped microchannel condenses Reactor (hydraulic diameter 300 μm, number of channels 4) and T-shaped microchannel oxidation reactor (hydraulic diameter 1000 μm, number of channels 1), through circulating water to control the discharge temperature of the intermediate heat exchanger to 10 ℃, in a 500mL stirred tank The product was collected internally, filtered, washed and dried to obtain tetramethylthiuram disulfide with a purity of 98.7%, and a solid yield of 99%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com