Chemical nickel wastewater treatment method and treatment system used by same

A treatment system and treatment method technology, applied in the field of chemical nickel wastewater treatment method and its treatment system, can solve the problems of large dosage, high treatment cost, difficult removal, etc., and achieve improved replacement, simple treatment method, and water discharge good water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

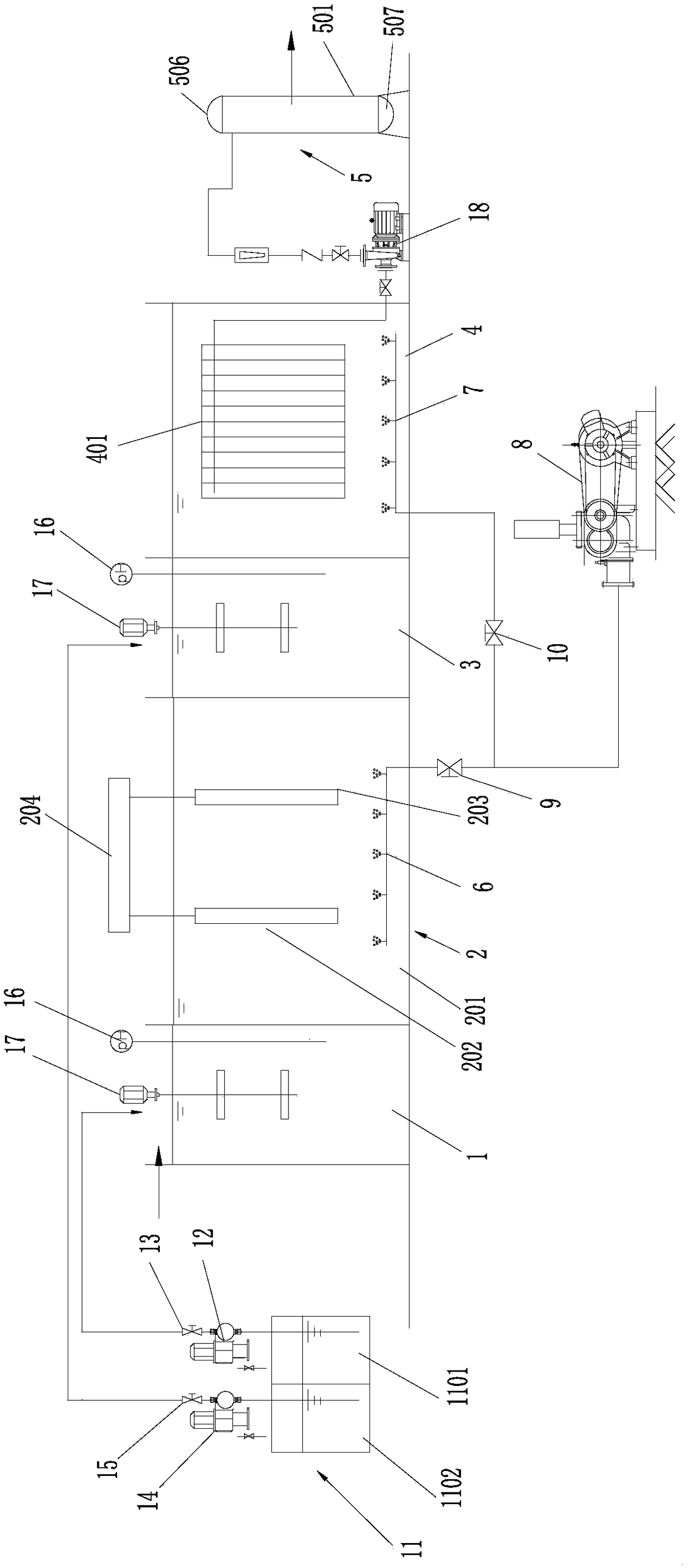

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0025] A treatment method for chemical nickel waste water, comprising the steps in turn:

[0026] (1) Pass the chemical nickel wastewater into the pH adjustment tank 1, adjust its pH value by adding sulfuric acid to make it acidic, and conduct online monitoring through the pH meter 16 in the pH adjustment tank 1 to accurately control the dosage of sulfuric acid.

[0027] (2) The wastewater in the pH adjustment tank 1 flows into the electrocoagulation system 2 by itself. The electrocoagulation system 2 includes a first electrode 202 and a second electrode 203. The first electrode 202 is an anode, the second electrode 203 is a cathode, and the first electrode 202 The material is iron. When the wastewater passes through the electrocoagulation system 2, the basic reaction process is as follows:

[0028] Anode reaction: Fe+2e→Fe 2+ ;

[0029] Cathodic re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com