Stretched multilayer thermoplastic resin film

A technology of thermoplastic resin and stretched film, applied in the direction of synthetic resin layered products, layered products, instruments, etc., can solve the problems of deterioration, easy increase of birefringence, appearance of film breakage, etc., and achieve moisture resistance and heat resistance Excellent, high light transmittance, excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0079] Hereinafter, the present invention will be specifically described by way of examples. However, the present invention is not limited by these Examples and Comparative Examples. The thermoplastic resin laminated stretched films obtained in Examples and Comparative Examples were evaluated as follows.

[0080]

[0081] For the thermoplastic resin obtained in the following synthesis examples, it was determined from the decrease rate of the absorption at 260 nm in the UV spectrum measurement before and after the hydrogenation reaction. From the absorbance A1 at the resin concentration C1 before the hydrogenation reaction, and the absorbance A2 at the resin concentration C2 after the hydrogenation reaction, it is calculated by the following formula.

[0082] Hydrogenation rate = 100×[1-(A2×C1) / (A1×C2)]

[0083]

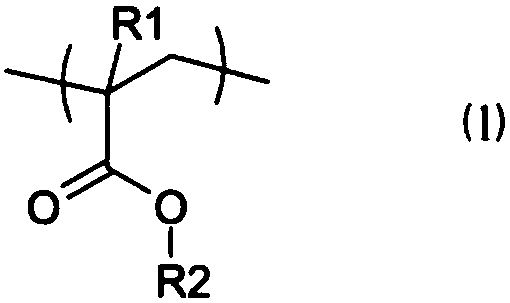

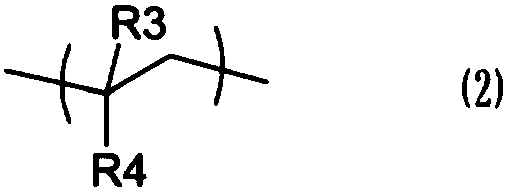

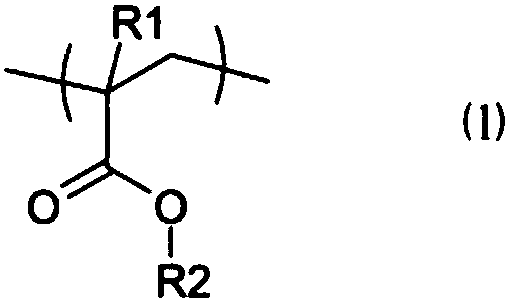

[0084] For the thermoplastic resin obtained in the following synthesis example, the dielectric polarization difference of the bonding unit of each structural un...

manufacture example 1

[0110] Production example 1 [production of methacrylic resin (A1)]

[0111] 100 parts by weight of methyl methacrylate (Sumitomo Chemical Co., Ltd. SUMIPEX MG5 (intrinsic birefringence: -0.0043, glass transition temperature: 105°C)) and 1.2 parts by weight of a triazine-based ultraviolet absorber (ADEKA Co., Ltd. Production of ADEKA STAB LA-F70) is continuously introduced into a twin-screw extruder with a shaft diameter of 30mm, and extruded at a barrel temperature of 250°C and a discharge speed of 25kg / h to obtain methyl methacrylate added with ultraviolet rays Absorbent methacrylic resin (A1).

Embodiment 1

[0112] Example 1 [resin (B1) / resin (A1) / resin (B1), layer ratio 1:3:1, stretching temperature 150°C]

[0113] Use the multi-layer extruding device that has the single-screw extruder of shaft diameter 32mm, the single-screw extruder of shaft diameter 65mm, the feed block that links with full extruder and the T die that links with feed block, form stack layers. The vinyl copolymer resin (B1) obtained in Synthesis Example 1 was continuously introduced into a single-screw extruder with a shaft diameter of 32 mm, and extruded at a barrel temperature of 250° C. and a discharge rate of 24.0 kg / h. Further, the methacrylic resin (A1) obtained in Production Example 1 was continuously introduced into a single-screw extruder with a shaft diameter of 65 mm, and extruded at a cylinder temperature of 250° C. and a discharge rate of 36.0 kg / h. The feed block connected to the full extruder is equipped with two types of three-layer distribution pins, and the temperature is set at 250°C, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com