Flame-retardant gel electrolyte, preparation method and application of flame-retardant gel electrolyte in lithium ion battery and supercapacitor

A gel electrolyte and electrolyte technology, applied in solid electrolytes, non-aqueous electrolytes, hybrid capacitor electrolytes, etc., can solve the problem of reducing the capacity and performance of lithium-ion batteries and supercapacitors, reducing the ionic conductivity and electrochemical stability of electrolytes , electrolyte leakage and other problems, to achieve the effect of reducing the possibility of electrolyte leakage, simple preparation method and increasing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

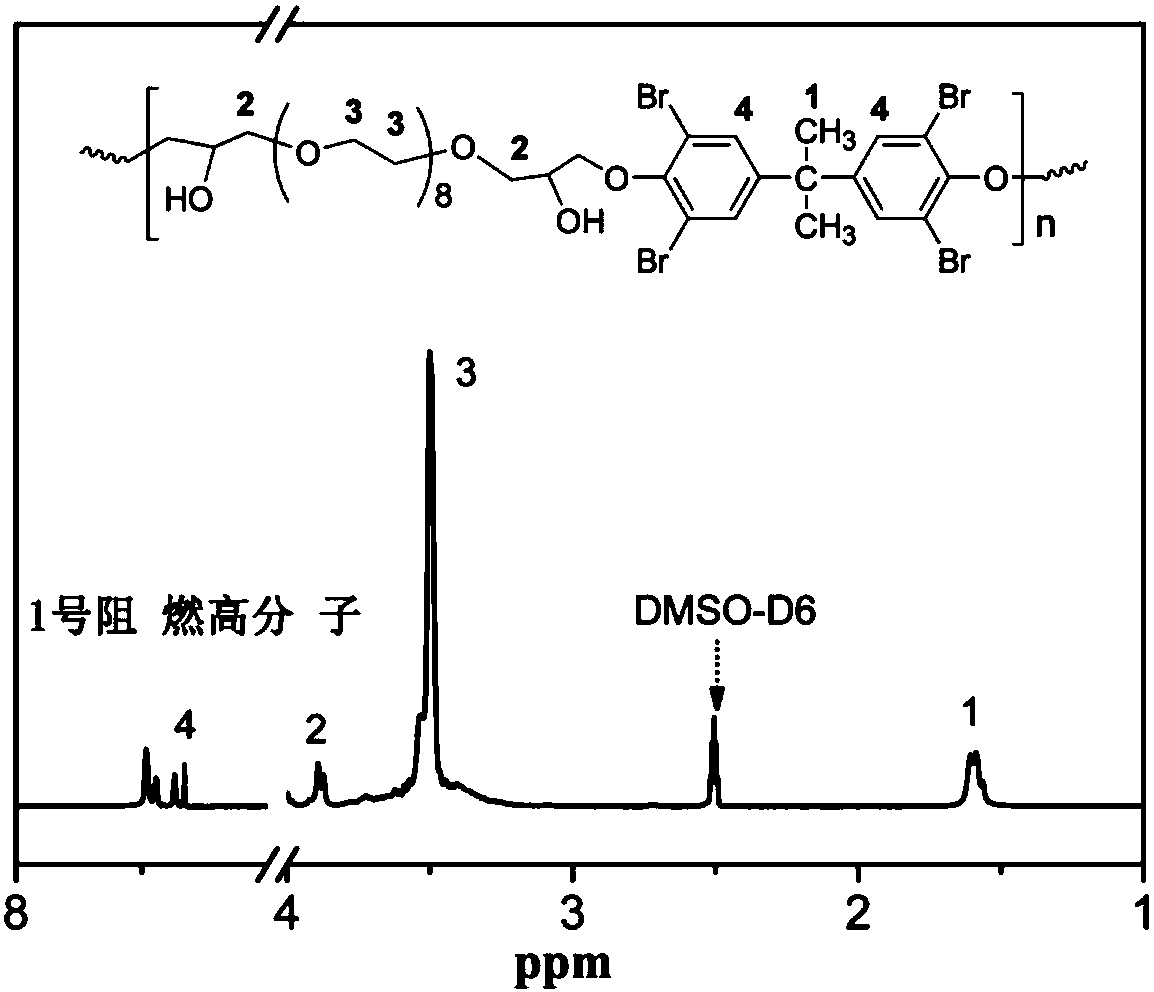

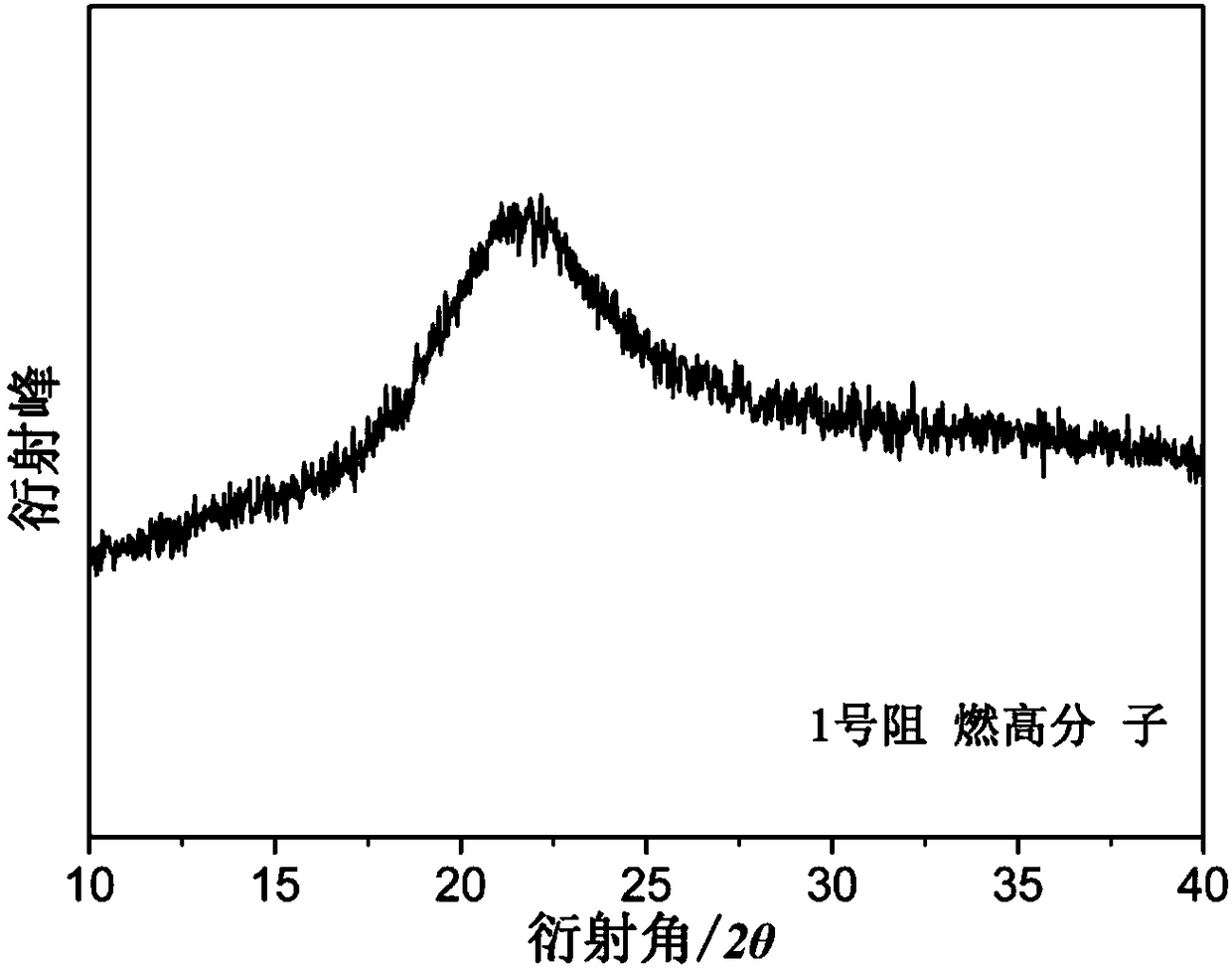

[0031] Example 1: The molecular chain structure is composed of tetrabromobisphenol A and polyethylene glycol diglycidyl ether (M n =500) Preparation of No. 1 flame-retardant polymer

[0032] 1) Under room temperature and nitrogen atmosphere, add 5g of polyethylene glycol diglycidyl ether with a number average molecular weight of 500 and 5.34g of tetrabromobisphenol A into a two-necked flask reaction vessel with mechanical stirring, and heat to 60 degrees , Stir thoroughly until the reactants are completely dissolved;

[0033] 2) Continue to heat up to 100 degrees, react for 10 hours, until a viscous clear liquid is formed, and cool to room temperature to obtain 10.34g of No. 1 flame-retardant polymer.

Embodiment 2

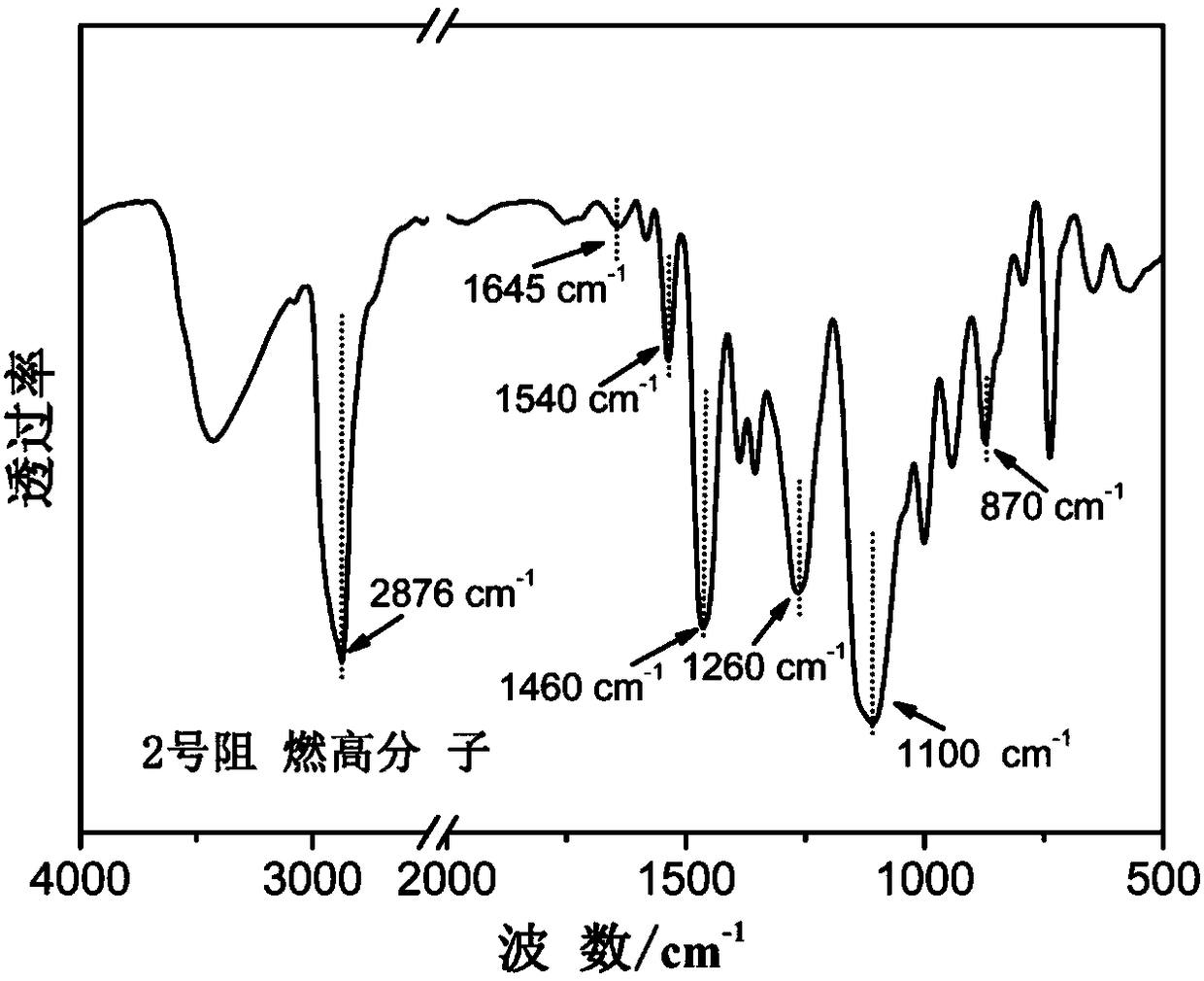

[0034] Example 2: The molecular chain structure is composed of tetrabromobisphenol A, tetrabromobisphenol A (bis-2-hydroxyethyl) ether and polyethylene glycol diglycidyl ether (M n =2000) Preparation of No. 2 flame-retardant polymer

[0035] Change 5g polyethylene glycol diglycidyl ether with a number average molecular weight of 500 in step 1) of Example 1 to 10g polyethylene glycol diglycidyl ether with a number average molecular weight of 2000, and 5.34g tetrabromobisphenol A Change to 1.34g tetrabromobisphenol A, 1.58g tetrabromobisphenol A (bis-2-hydroxyethyl) ether; the temperature in step 2) is changed from 100 degrees to 110 degrees, and the rest of the steps are as described in Example 1. 12.92g of No. 2 flame-retardant polymer was obtained.

Embodiment 3

[0036] Example 3: Preparation of No. 1 flame retardant gel electrolyte

[0037] 1) In an argon glove box, add 1 g of ethylene carbonate and 1 g of propylene carbonate to the container, and stir uniformly to obtain a mixed organic solvent;

[0038] 2) Weigh 2g of lithium hexafluorophosphate and add it to step 1) Mixed organic solvent, stir until the lithium salt is completely dissolved, then add 6g of the No. 1 flame-retardant polymer prepared in Example 1, and stir until the flame-retardant polymer is completely dissolved and a clear viscous is obtained Like a gel liquid, the No. 1 flame-retardant gel electrolyte was prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com