Insulated container based on integral cold storage plate and cold filling and cold supply method of insulated container

A technology of cold storage board and container, which is applied to household refrigeration devices, packaging, refrigerators, etc., can solve the problems of affecting turnover efficiency, leakage of heat exchange coils, and high maintenance costs, so as to meet the requirements of multimodal transportation and eliminate the possibility of leakage. The effect of simplifying the difficulty of manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

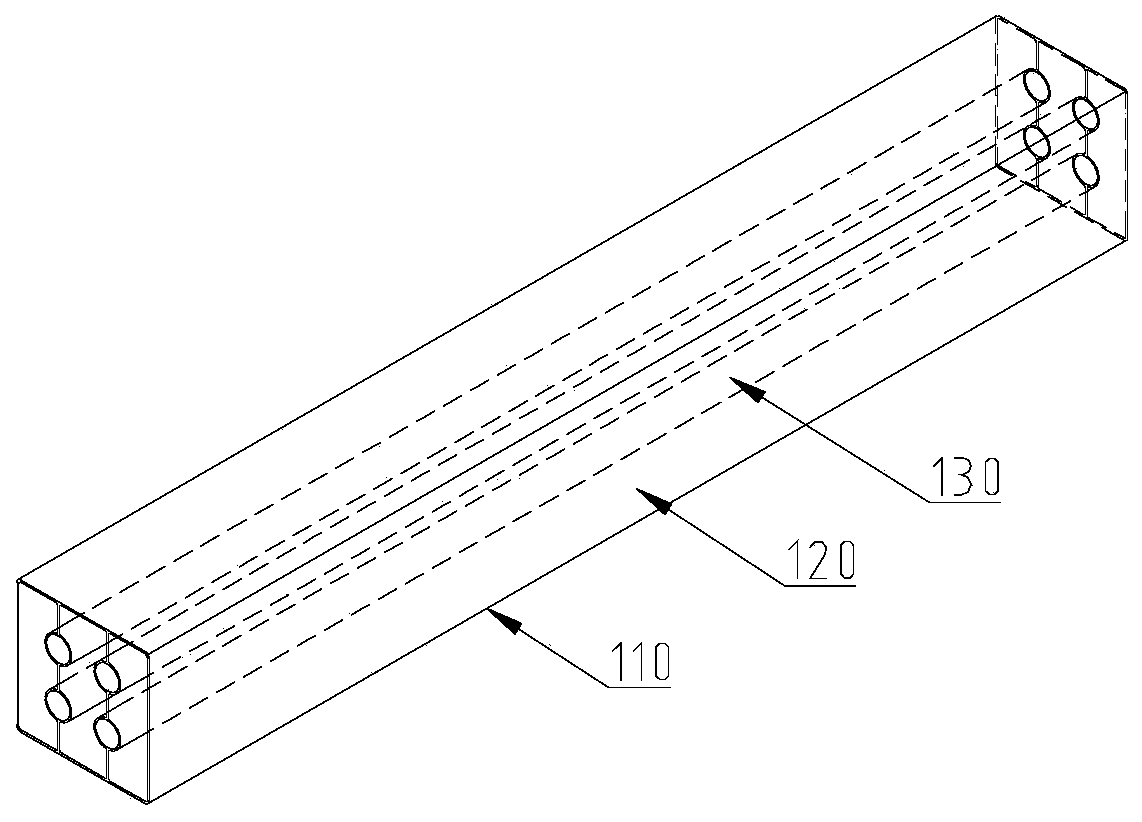

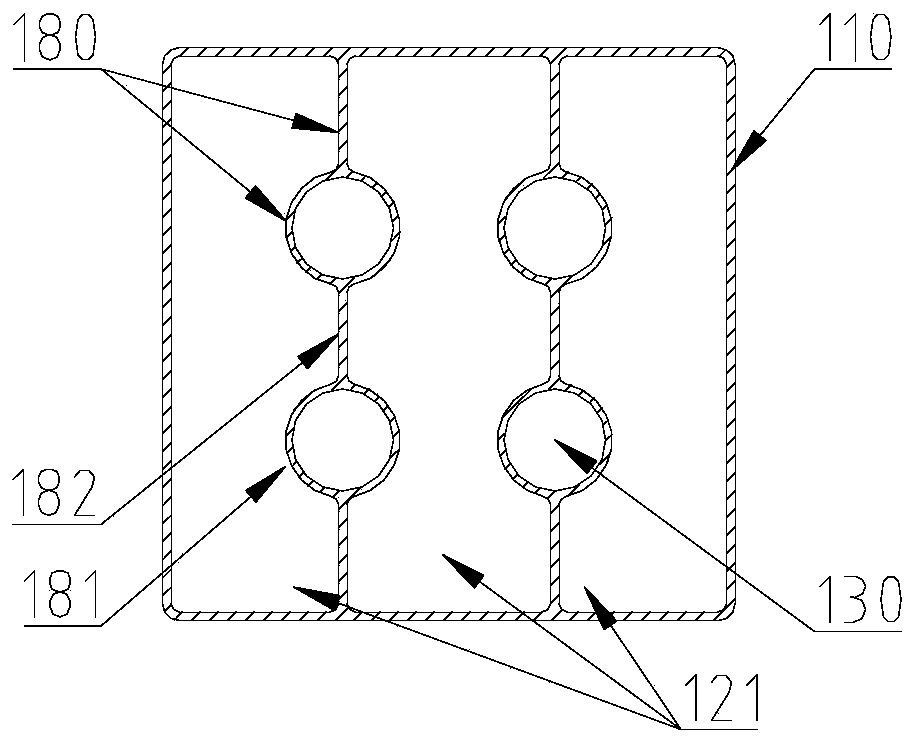

[0046] Such as Figure 2-9 As shown, this embodiment provides an integral cold storage plate, including a cold storage plate shell 110 and a longitudinal partition 180 arranged in the cold storage plate shell 110, and the cold storage plate shell 110 and the longitudinal partition 180 are integrally drawn by a profile The stretch forming process stretches into a uniform overall structure.

[0047] The longitudinal partition 180 isolates a part of the space in the cold storage plate shell 110 as the cold charging channel 130 for the brine 500 to pass through, and the rest of the space is used as the cold storage liquid chamber 120 filled with the cold storage liquid 400 . The longitudinal partition 180 is composed of a channel partition 181 forming the cold charging channel 130 , and a connecting rib 182 connected between the channel partition 181 and the cold storage plate housing 110 and between different channel partitions 181 .

[0048] The cold storage liquid cavity 120 i...

Embodiment 2

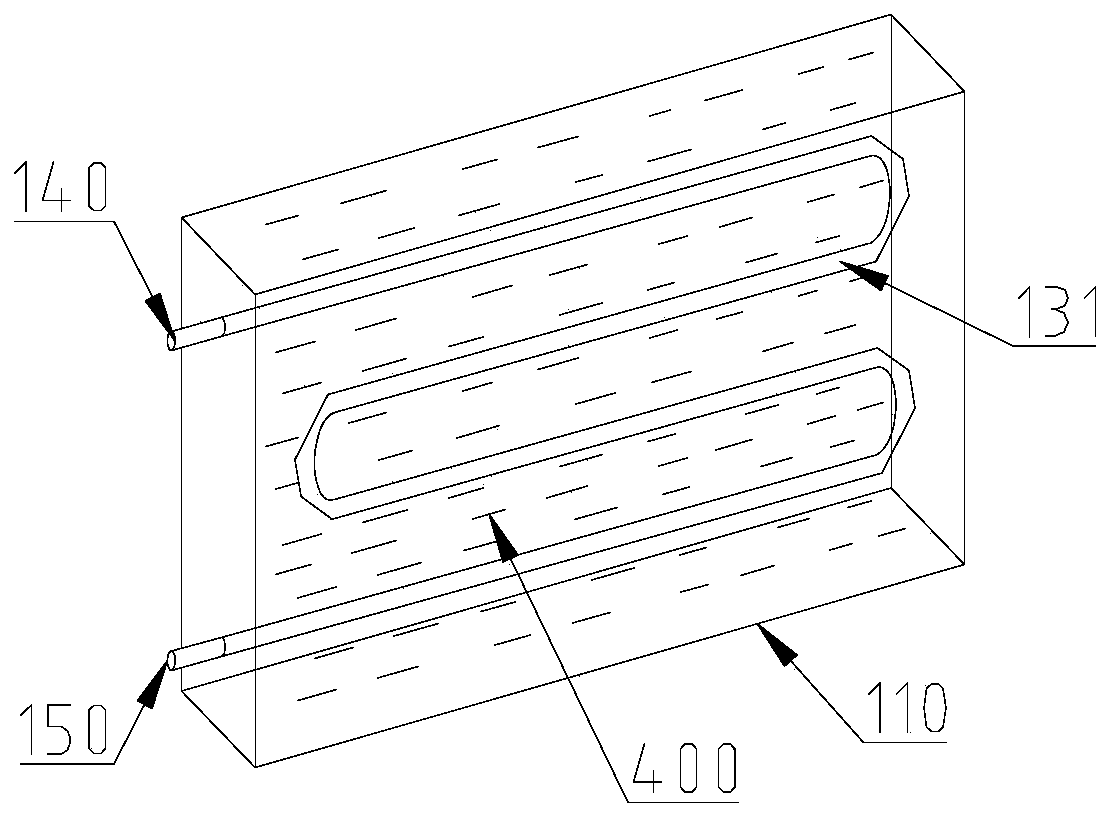

[0054] Such as Figure 10-16 As shown, this embodiment provides an insulated container, which includes a container body 200 with an insulated box wall 210 , and a cold storage plate device and a cold charging pipeline system 300 are arranged in the container body 200 .

[0055] The heat insulation box wall 210 has a sandwich structure, including an inner wall plate 211, an outer wall plate 212 and an insulating layer 213 sandwiched between them. The insulating layer 213 is made of polyurethane foam material and has the function of heat preservation and heat insulation. The heat insulation box wall 210 comprises a top plate 220 , a side plate 230 , a bottom plate 240 , a front wall 250 and a box door 260 according to specific positions.

[0056] The cooling pipeline system 300 is arranged near the wall surface of the heat insulation box wall 210 , and includes a brine inlet pipe 330 , a brine return pipe 340 and a cooling interface. The cooling interface includes a cooling liq...

Embodiment 3

[0060] This embodiment provides a method for charging and cooling the insulated container in Embodiment 2, including two processes of charging and cooling, wherein:

[0061] Before the insulated container is transported, the cold storage plate 100 in it is pre-charged by the cold charging station. The specific cold charging steps are as follows: the brine 500 from the cold charging station enters the brine inlet 140 into the brine inlet pipe 330 reaches the liquid storage tank 160 at one end of the cold storage plate 100; then divides into a plurality of branches and enters the cold charging channel 130 of each cold storage plate 100, and cools the cold storage liquid 400 in each cold storage plate 100, so that the temperature of the cold storage liquid 400 is reduced to a corresponding level. Phase change occurs at or below the phase change point to store cold storage capacity; after the brine 500 exchanges heat in the cooling channel 130, it flows out of the cooling channel 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com