Shoe-type automatic clutch

An automatic clutch, clutch technology, applied in the direction of automatic clutch, clutch, mechanical equipment, etc., can solve the problems of uneven wear of friction block, shorten the service life of friction block, reduce contact area, etc., to simplify the production process and production difficulty, Reliable power transmission and the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

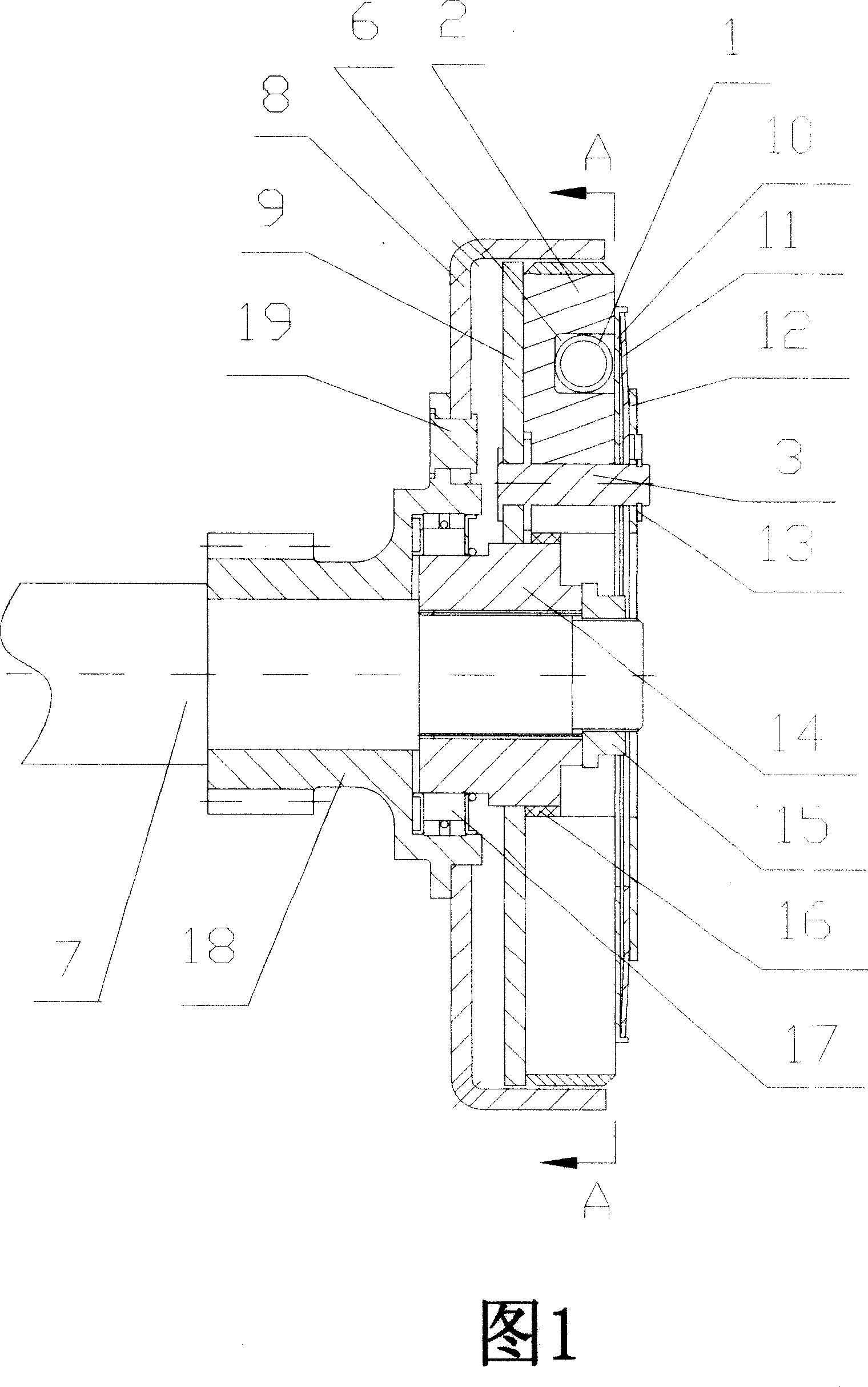

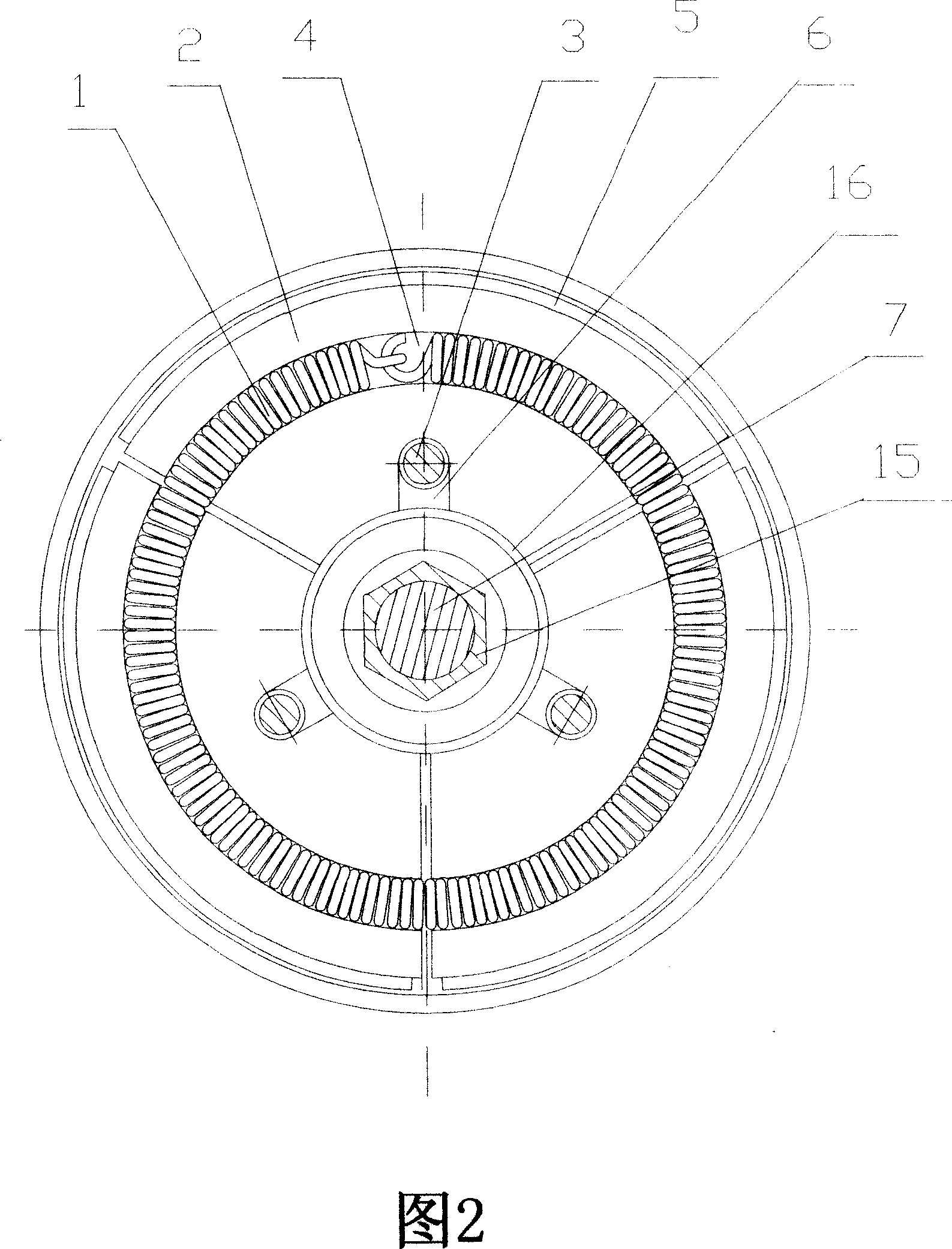

[0011] Referring to FIG. 1 and FIG. 2 , the clutch cover 8 is connected with the driven gear 18 with a shaft hole, and is tightly fixed by a rivet 19 . The shaft hole of the driven gear 18 is a stepped hole, the driving disc 9 is located in the clutch cover 8, and the driving disc 8 is fixedly connected to a shaft sleeve 14 with a spline hole by welding, and the shaft sleeve 14 and the driven gear 18 on the same axis line, the shaft sleeve 14 slides and fits with the inner wall of the large end of the stepped hole of the driven gear 18 through the one-way device 17, and the shaft sleeve 14 with spline holes corresponds to one end of the centrifugal shoe 2. The circumference is covered with rubber Set of 16. Three pin shafts 3 are evenly distributed on the driving disc 9, and the three pin shafts 3 are equally divided into 360°, and are respectively fixed on the driving disc 9 by riveting, or fixed on the driving disc 9 by nut pressing to achieve the same effect. Three centrif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com