Drilling clamp for special cover body

A drilling jig and cover technology, which is applied in the direction of drilling molds for workpieces, manufacturing tools, metal processing machinery parts, etc., can solve problems such as inability to process, high tool requirements, difficult processing, etc., to simplify the design difficulty, The effect of simplifying manufacturing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

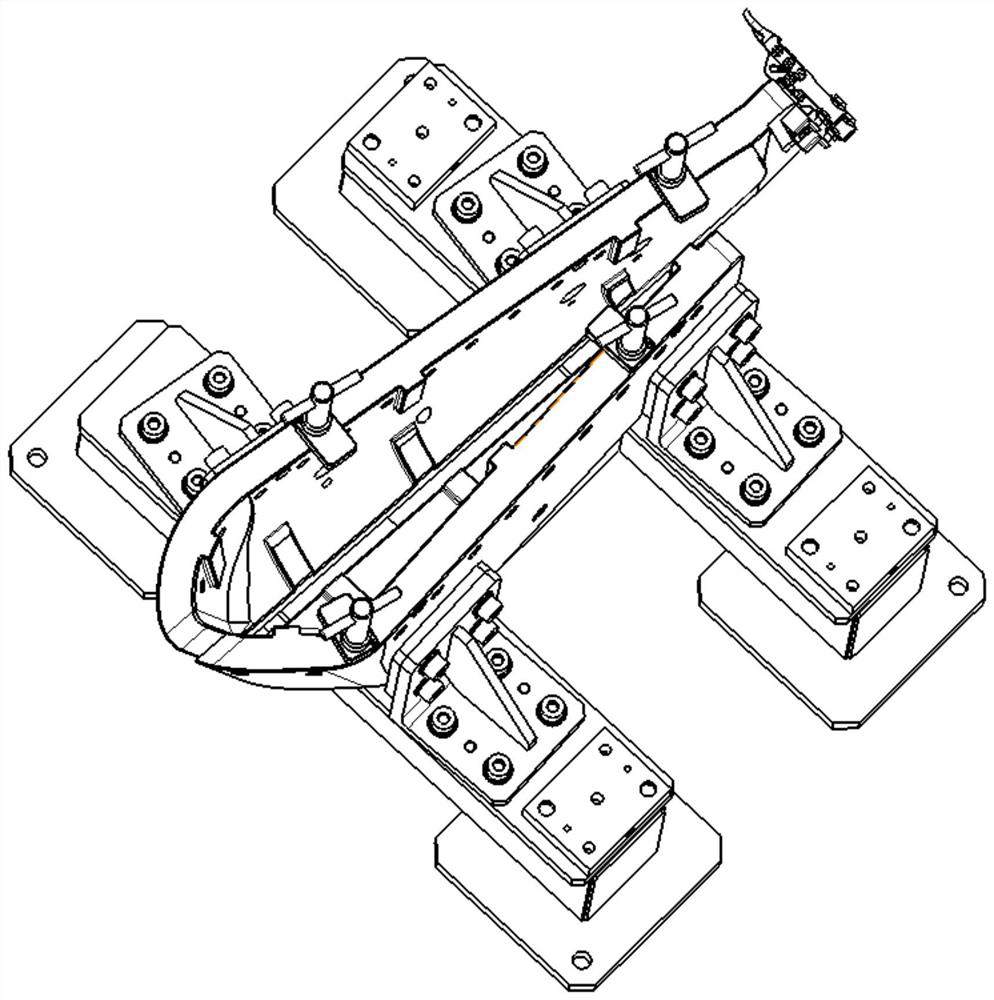

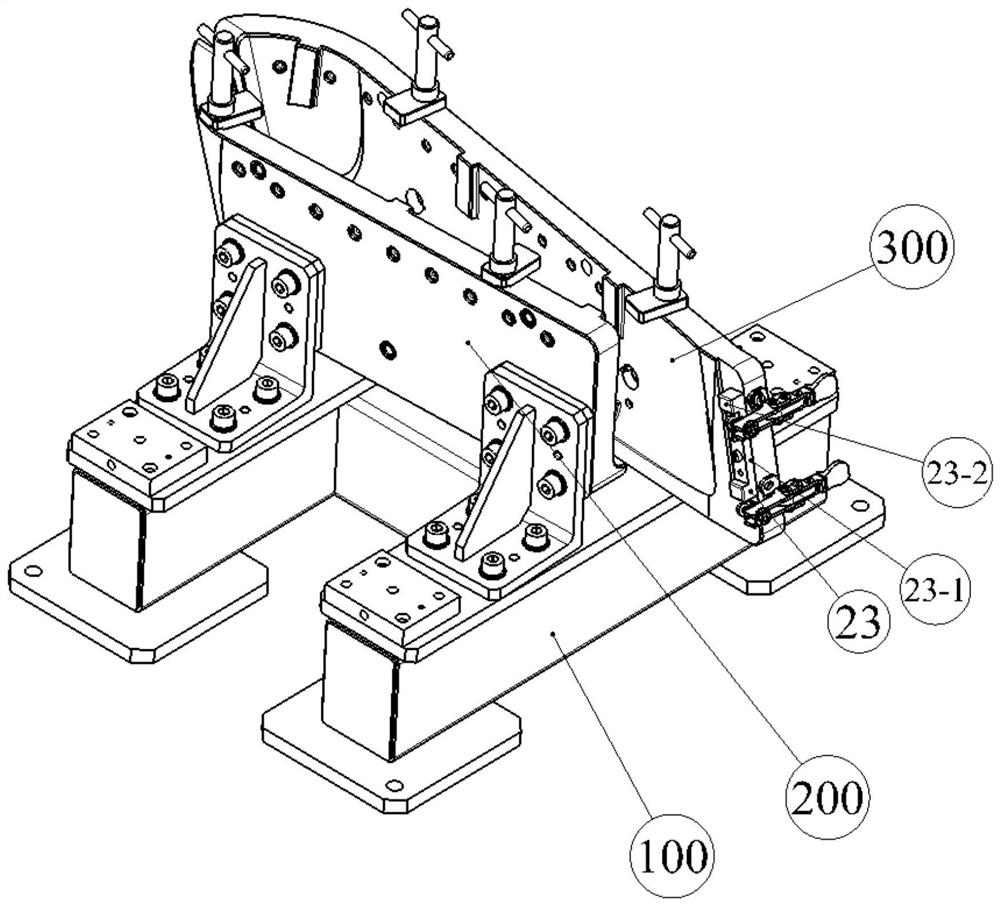

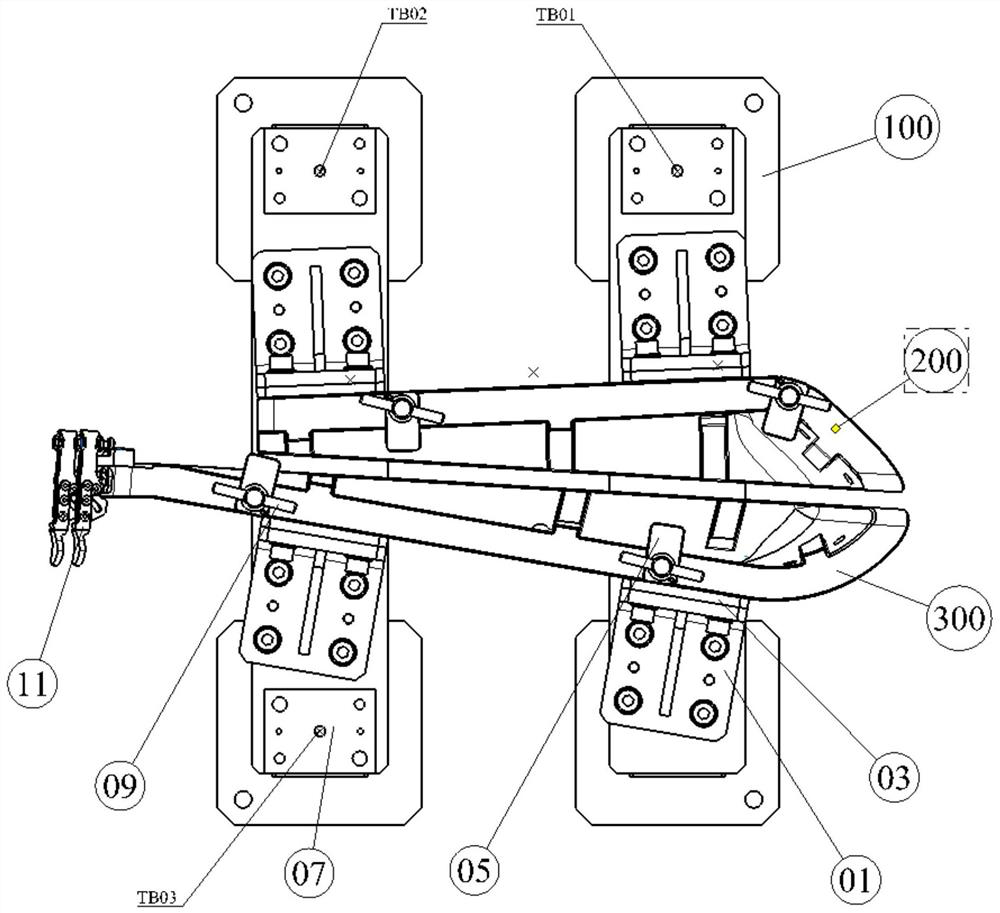

[0022] see Figure 1~9, a drilling jig with a special cover body, consisting of the first jig assembly 200, the second jig assembly 300, the mounting base 100, the connecting angle steel 01, the adjusting gasket 03, the three measuring standard seats 07, the clip The first drilling template assembly 200 consists of a left "half boat"-shaped drilling template 201, a first origin bushing 203, N first drill bushings 205, a A steel wire screw sleeve 207 and clamping pin steel wire screw sleeve 211 are formed. The outer surface of the left "half boat" shaped drilling template is provided with a datum plane A, which is perpendicular to the datum plane A on the left "half boat" shaped drilling template. There are three origin bushing bottom holes processed on the top, and the first origin bushing is installed on the origin bushing bottom hole with an interference fit. The coordinate system constructed with the datum plane A and the origin bushing bottom hole, the left "half" The inn...

Embodiment 2

[0026] The left "half boat" shaped drilling template and the right "half boat" shaped drilling template can also be movably installed on the mounting base in the form of slide rails. After the final theoretical correct positions of the left "half boat" shaped drill template and the right "half boat" shaped drill template are determined by the laser tracker, the left "half boat" shaped drill template and the right "half boat" shaped drill template are Positioning pins are set between the "boat"-shaped drilling templates for plug-in fixation. When the left "half-boat"-shaped drilling template and the right "half-boat"-shaped drilling template are slidable, the problem that the opening and closing angle of some special covers cannot be put into the drilling jig is solved, which is convenient for clamping Work.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com