A kind of negative electrode for lithium secondary battery and preparation method thereof and lithium secondary battery

A technology of lithium secondary battery and negative electrode, which is applied in the field of negative electrode for lithium secondary battery and its preparation, can solve the problems such as large change in the structure and morphology of lithium powder electrode, high specific surface area of powder porous electrode, and reduced negative electrode reactivity, etc. Achieve the effect of improving electrochemical performance, inhibiting growth and drastic volume change of electrodes, and improving interface stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

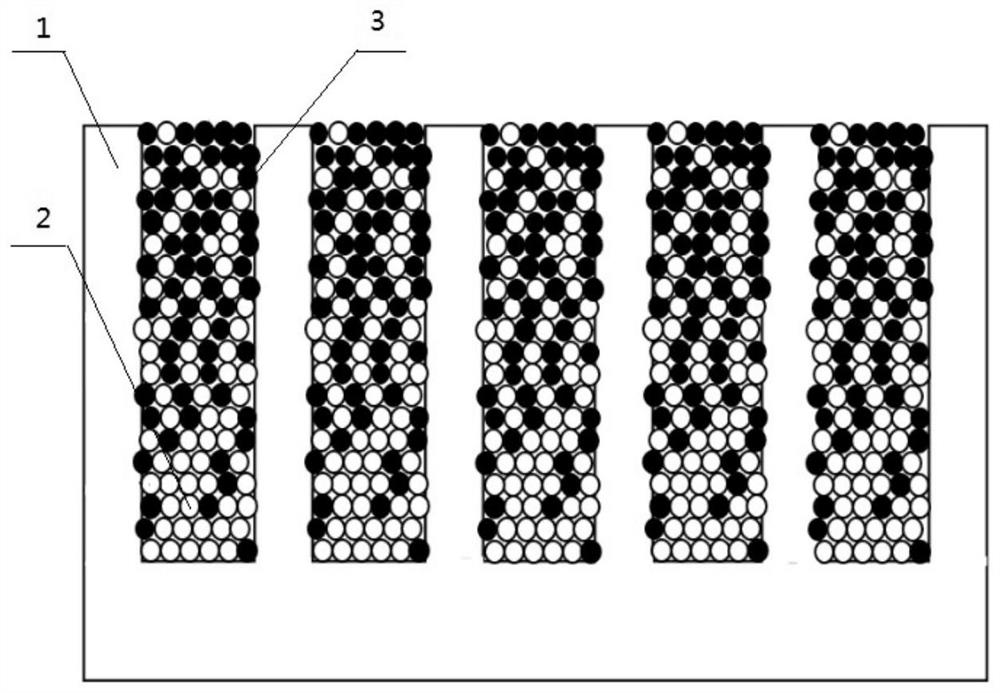

[0039]A negative electrode for a lithium secondary battery. The negative electrode for a lithium secondary battery is mainly composed of a raised array electrode skeleton 1, a nanoscale alloy skeleton 3, and an active metal lithium 2. The raised array electrode with a large aperture The material of the skeleton is any one of Cu, Al, Sn, Fe, Co, Ni, Zn, In, and the nanoscale alloy skeleton includes lithium and non-lithium elements, and the non-lithium element materials include Sn, At least one of Si, Cu, In, Al, Mg, Ge, Zn, Ni, the active metal lithium is filled in the pores of the nano-scale alloy framework, and fully contacts with the nano-scale alloy framework to form a lithium-rich alloy. The lithium-rich alloy is deposited in the pores of the raised array electrode skeleton.

[0040] In the negative electrode for a lithium secondary battery described in this embodiment, the cross-sectional shape of the protrusion array in the protrusion array electrode skeleton is any one ...

specific Embodiment approach 2

[0045] According to the preparation method of the lithium secondary battery negative electrode described in specific embodiment 1, comprises the following steps:

[0046] Step a, preparing a convex array electrode skeleton by a template method;

[0047] Step b, vacuum evaporation or magnetron sputtering to prepare a nanoscale alloy skeleton and fill it with active metal lithium.

[0048] In the preparation method of the negative electrode for lithium secondary battery described in this embodiment, the preparation of the porous template in the raised array electrode skeleton in step a adopts a polycarbonate film with a thickness of 20 μm, and the bombardment by nuclear fission fragments causes damage marks to appear, Then chemical etching is used to corrode the traces into holes to prepare a porous template.

[0049] In the preparation method of the negative electrode for lithium secondary battery described in this embodiment, the vacuum evaporation in step b is prepared in a ...

specific Embodiment approach 3

[0054] According to the lithium secondary battery described in Embodiment 1, the lithium secondary battery includes a casing and a negative electrode for a lithium secondary battery, a positive electrode, an organic electrolyte, and a separator placed in the casing, and the lithium secondary battery The negative electrode for the battery includes a convex array electrode framework, a nanoscale alloy framework and an excessive amount of active lithium metal. The active metal lithium is filled in the pores of the nanoscale alloy framework to form a lithium-rich alloy. The lithium-rich alloy is deposited on the In the pores of the array electrode skeleton.

[0055] According to the lithium secondary battery described in specific embodiment 1, the provided graded lithium-rich alloy negative electrode for the lithium secondary battery reduces the current density, promotes the uniform distribution of current in the lithium-rich alloy, and effectively suppresses the formation of lithi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com