Tire leakage speed detecting device

A detection device and tire technology, applied in tire measurement, measurement devices, tire parts, etc., can solve problems such as tire burst, slow driving, and unstable vehicle body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the embodiments given in the accompanying drawings.

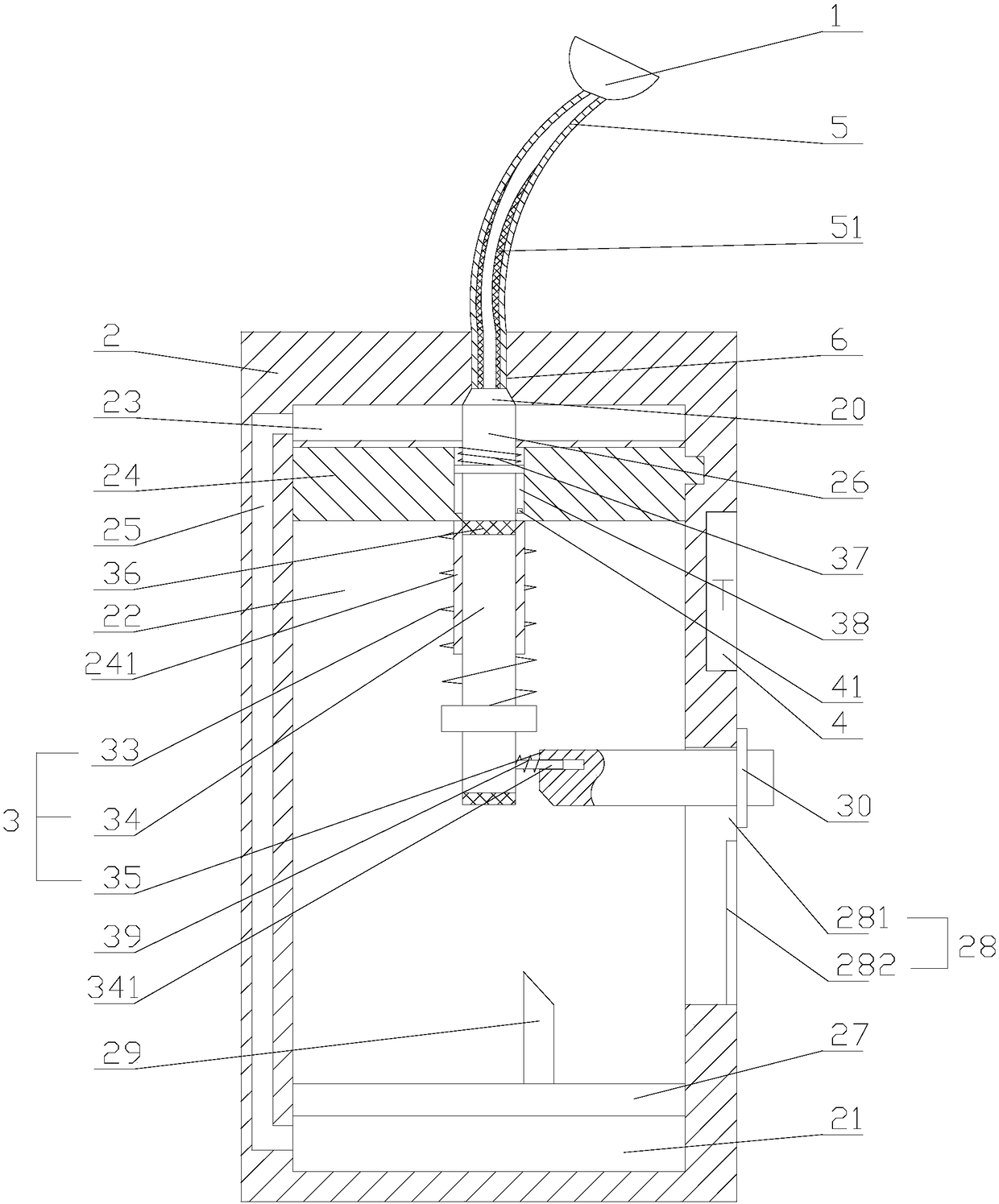

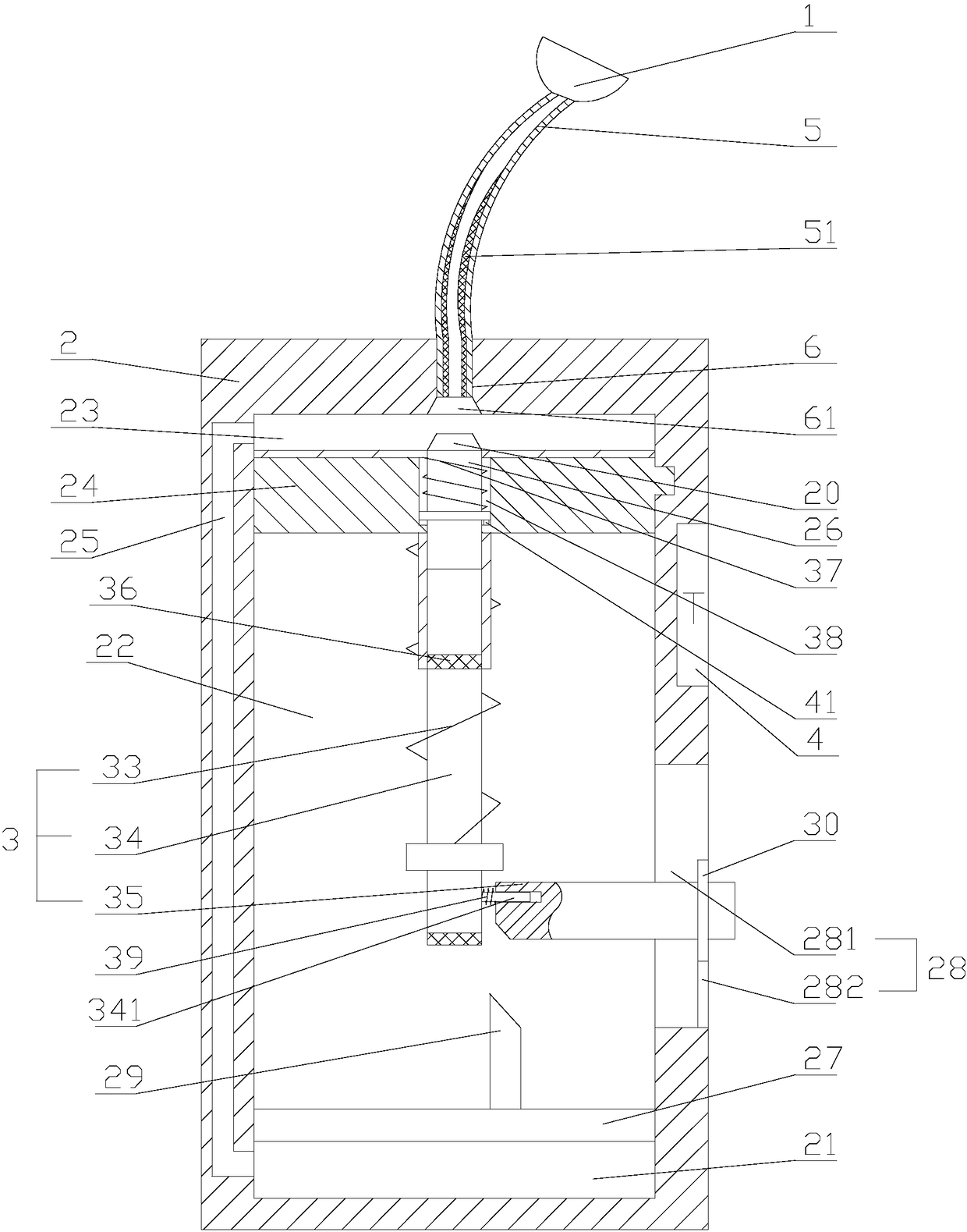

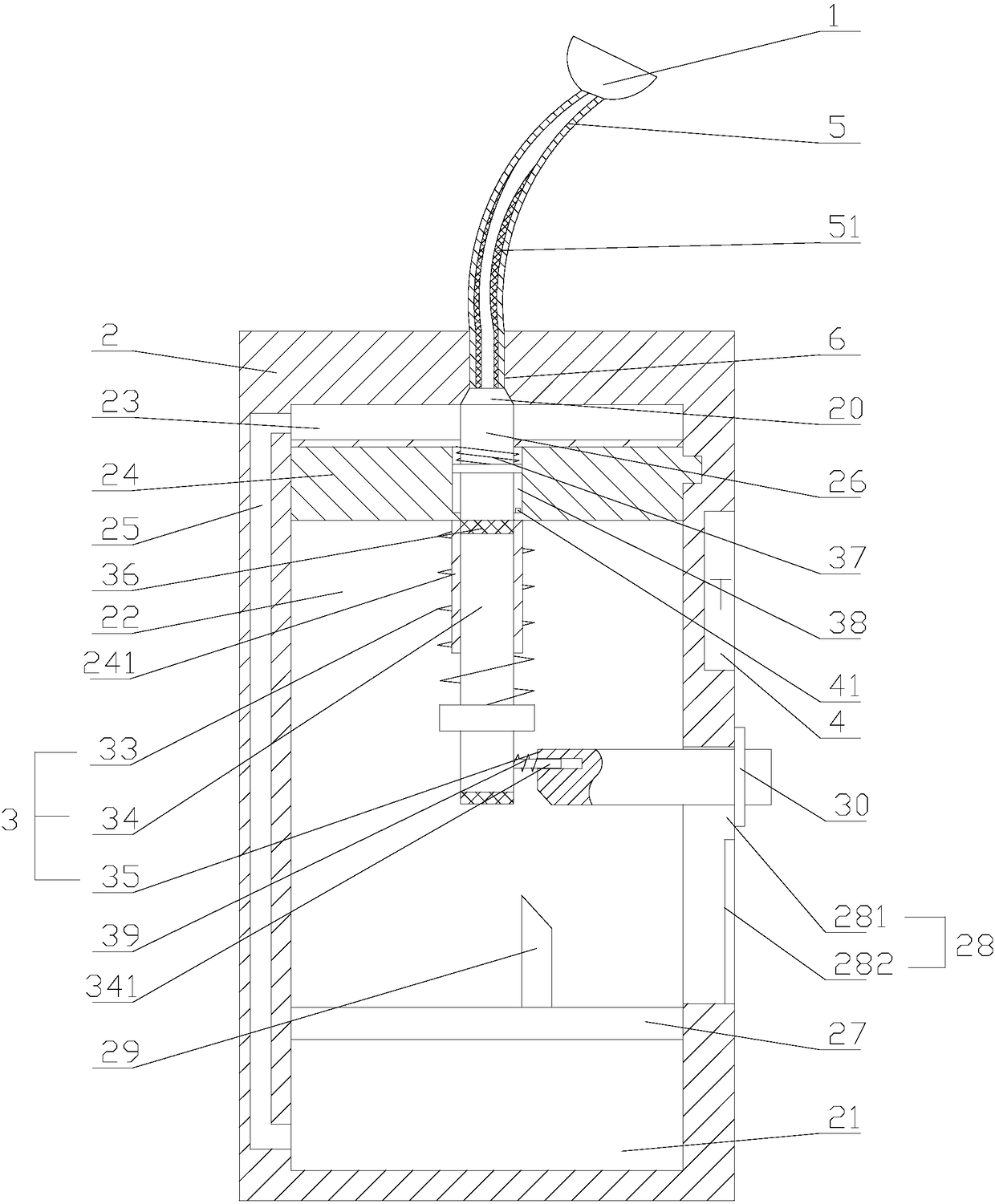

[0018] refer to Figure 1 to Figure 3 As shown, the detection device of a tire air leakage speed in this embodiment includes an air collector 2 and an air nozzle 1 used to connect with the hole on the tire. The air collector 2 is connected to the air nozzle 1 through an air pipe 5, and The interior of the air cylinder 2 is provided with an air collection chamber 21, a sliding chamber 22 and an air intake chamber 23 sequentially along the axial direction of the air collection chamber 2, and a piston plate 27 is arranged between the air collection chamber 21 and the sliding chamber 22, and the piston plate 27 can be relatively assembled. The air cylinder 2 slides, a fixed plate 24 is arranged between the sliding chamber 22 and the air inlet chamber 23, and the air hole 6 communicating with the air supply nozzle 1 and the air inlet chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com