A high temperature resistant fire smoke exhaust fan

A smoke exhaust fan and high temperature resistant technology, which is applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve problems such as increased operating power, increased operating jitter, and cooling water leakage, so as to reduce the risk of leakage and improve the use of Efficiency, the effect of improving heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below with reference to the accompanying drawings and examples, and the implementation of the present invention includes but not limited to the following examples.

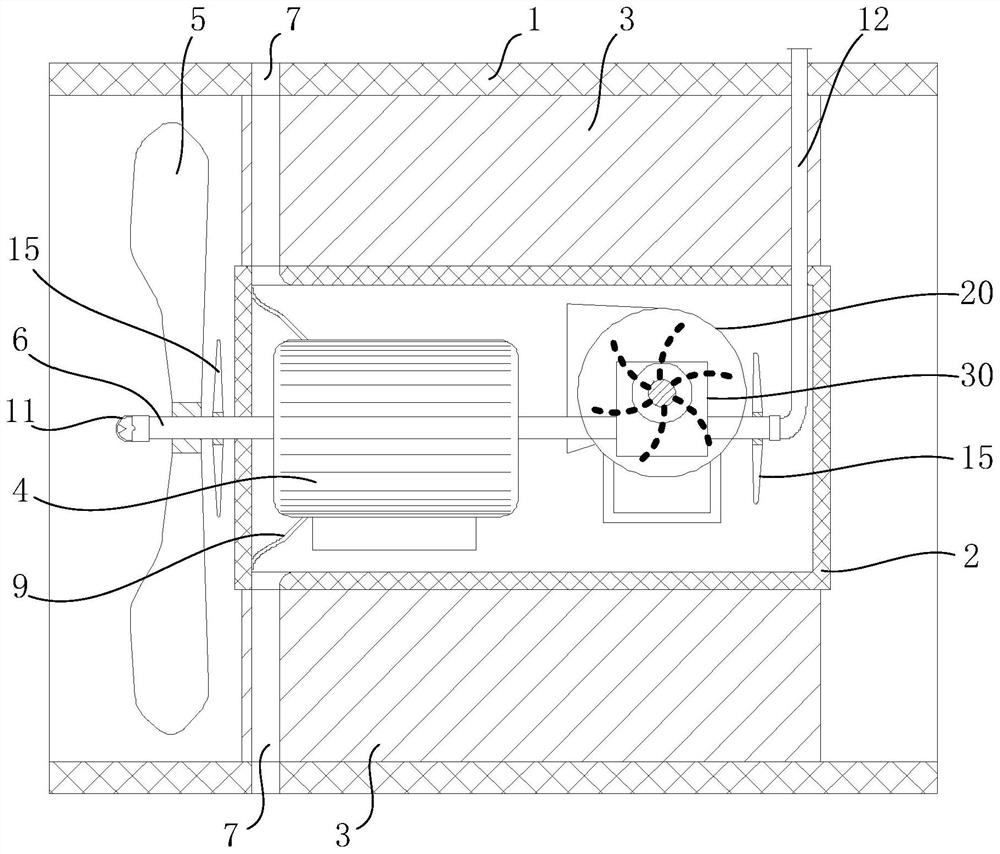

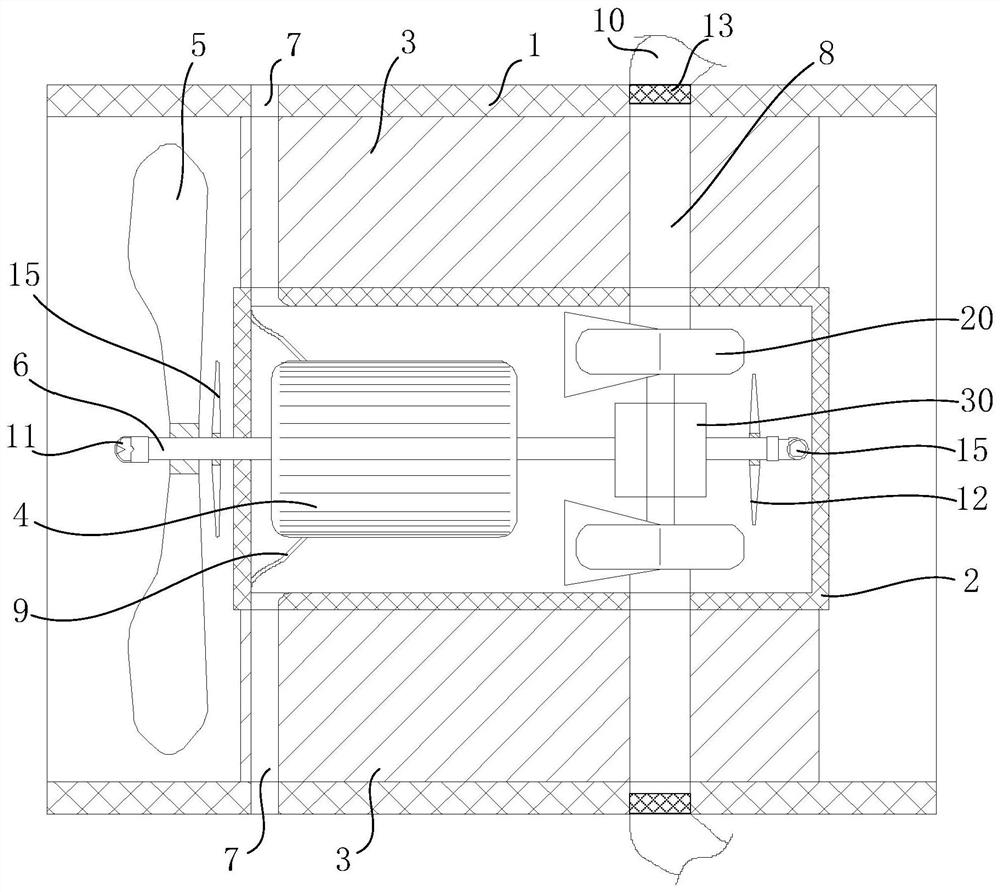

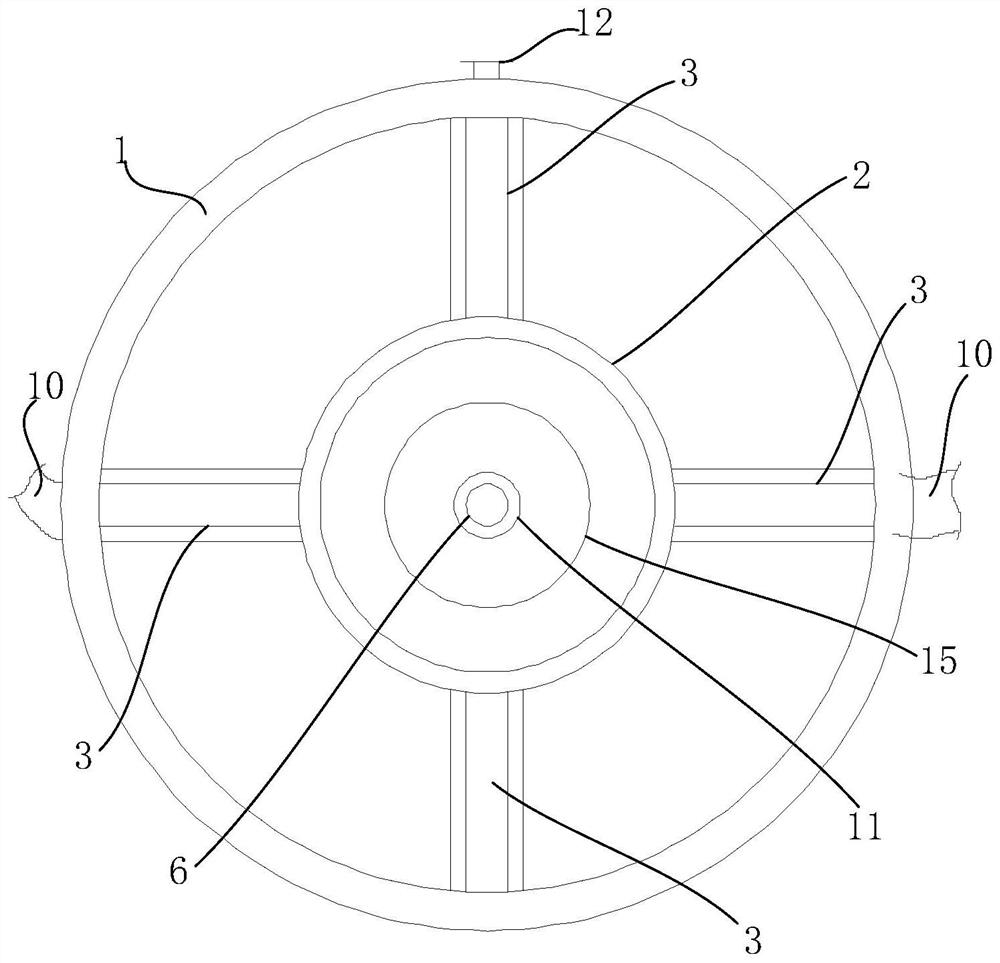

[0040] Such as Figure 1-10 As shown, the novel high-temperature-resistant fire-fighting smoke exhaust fan includes an outer cylinder 1 for exhausting smoke, a closed inner cylinder 2 coaxially arranged in the outer cylinder, and multiple connections between the outer cylinder and the inner cylinder. The flow guide support 3 fixed on the inner cylinder is coaxially placed in the inner cylinder and the through-axis motor 4 which maintains a certain heat dissipation gap with the inner wall of the inner cylinder is arranged in the outer cylinder and is located at the front end of the inner cylinder and protrudes from the through-axis motor. The smoke exhaust fan 5 connected to the rotating shaft 6 of the cylinder is opened inside the front part of the flow guidin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com