Aluminum silicon carbide material nickel plating method

A technology of aluminum silicon carbide and electroless plating, which is applied in the direction of liquid chemical plating, superimposed layer plating, metal material coating process, etc., can solve problems such as shedding, difficulty in metal plating on ceramic surfaces, and easy occurrence of pinhole plating, etc. Achieve the effect of bright coating, low cost and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

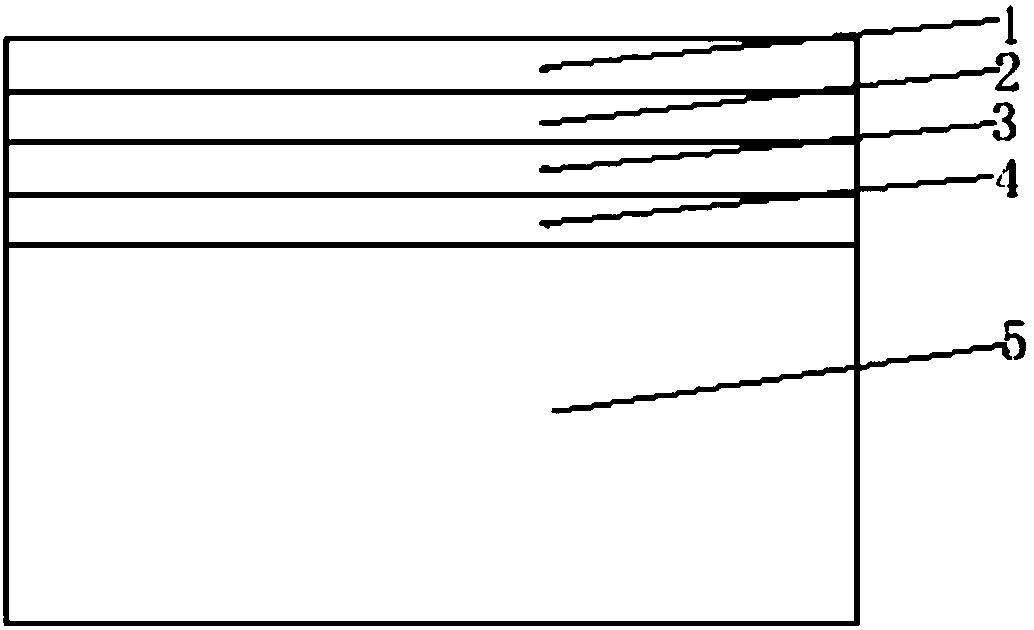

Image

Examples

Embodiment 1

[0037] S1. First degrease and dry with 40g / L acetone degreasing agent; then wash with water at a temperature of 30°C for 1min, clean with a special weak acid salt, decontaminate and activate the surface, room temperature (19°C), time 20Sec;

[0038] S2. The aluminum silicon carbide substrate is grounded with copper under vacuum, and then the surface is plated with nickel phosphorus with a thickness of 1um by physical vapor deposition, and washed with water according to step S1 after plating;

[0039] S3. Nickel immersion is prepared into a nickel plating solution by three solutions of nickel sulfate 300g / L, phosphoric acid 30g / L, and 40% hydrofluoric acid 30mL / L. The temperature is controlled at 19°C and the time is 20Sec for activation reaction, and then electroless nickel plating is carried out. Prime for 20 minutes, use Atotech 2060 medium phosphorus chemical nickel, wash with water according to step S1 after plating;

[0040] S4, carry out alkali washing by the solution pr...

Embodiment 2

[0043] S1. First degrease and dry with 40g / L acetone degreasing agent; then wash with water at a temperature of 50°C for 6 minutes, clean with a special weak acid salt, decontaminate and activate the surface, room temperature (26°C), time 40Sec;

[0044] S2. The aluminum silicon carbide substrate is grounded with copper under vacuum, and then the surface is plated with nickel phosphorus with a thickness of 3um by physical vapor deposition, and washed with water according to step S1 after plating;

[0045] S3. Nickel immersion is prepared by three solutions of nickel sulfate 300g / L, phosphoric acid 30g / L, and 40% hydrofluoric acid 30mL / L to prepare a nickel plating solution. The temperature is controlled at 22°C and the time is 40Sec to activate the reaction, and then electroless nickel phosphorus plating Prime for 50 minutes, use Atotech 2060 medium phosphorus chemical nickel, wash with water according to step S1 after plating;

[0046] S4, carry out alkali washing by the soluti...

Embodiment 3

[0049] S1. First degrease and dry with 40g / L acetone degreaser; then wash with water at a temperature of 70°C for 10 minutes, and then clean with a special weak acid salt to decontaminate and activate the surface at a temperature of 30°C and a time of 50Sec;

[0050] S2. The aluminum silicon carbide substrate is grounded with copper under vacuum, and then the surface is plated with nickel phosphorus with a thickness of 5um by physical vapor deposition, and washed with water according to step S1 after plating;

[0051] S3. Nickel immersion is prepared by three solutions of nickel sulfate 300g / L, phosphoric acid 30g / L, and 40% hydrofluoric acid 30mL / L to prepare a nickel plating solution. The temperature is controlled at 30°C and the time is 60Sec for activation reaction, and then electroless nickel phosphorus plating Prime for 80 minutes, use Atotech 2060 medium phosphorus chemical nickel, wash with water according to step S1 after plating;

[0052] S4, carry out alkali washing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com