Method of increasing content of polysaccharide in mycelia of lucid ganoderma by means of fungal polysaccharides, and lucid ganoderma product prepared therefrom

A technology of ganoderma mycelium and fungal polysaccharides, applied in the direction of microorganism-based methods, fungi, biochemical equipment and methods, etc., can solve the problems of low yield of ganoderma polysaccharides, limited effect of ganoderma polysaccharide content, etc., and achieve the goal of breaking polysaccharides The effect of low content, rich nutrition and high polysaccharide content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

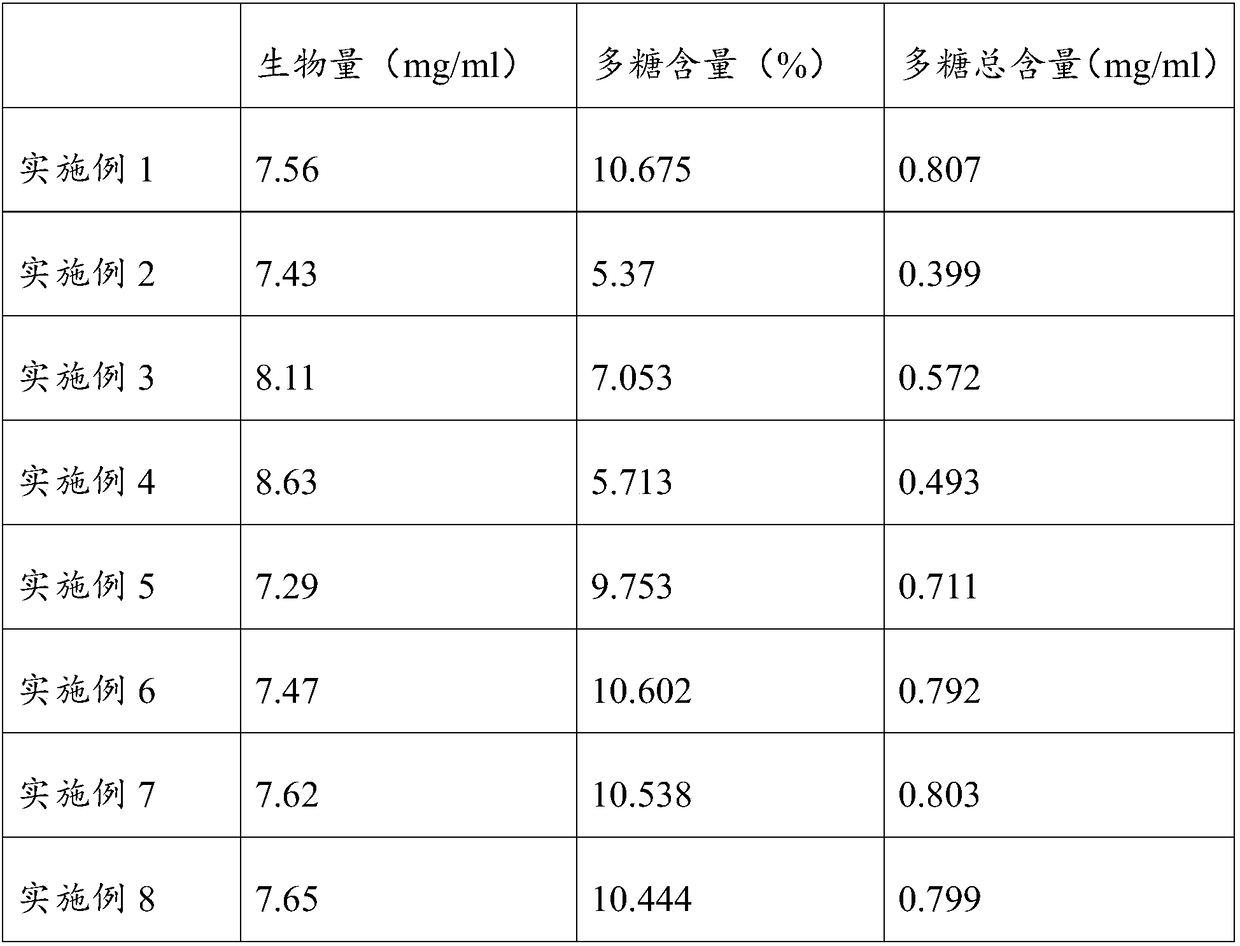

Examples

Embodiment 1

[0034] Embodiment 1 utilizes fungal polysaccharide to improve the method for polysaccharide content of ganoderma lucidum mycelium

[0035] 1. Preparation of fungal polysaccharides

[0036] 1.1. After activating the Monascus strain, inoculate it in a liquid medium for fermentation, and culture it in a shaker at 160r / min at 26°C for 6 days while avoiding light.

[0037] 1.2. After the cultivation, separate the mycelium, dry it in an oven at 55-65°C to constant weight, and grind it into powder.

[0038] 1.3. Add distilled water to the dry powder of filamentous mycelium at a ratio of 1:20, ultrasonically extract for 10 minutes (50°C, 200W), centrifuge for 20 minutes, and collect the supernatant.

[0039] 1.4. Add distilled water to the residue according to the above ratio, extract at 100°C, combine the supernatants, and add 3 times the volume of 95% ethanol for ethanol precipitation for 24 hours, centrifuge and discard the supernatant to obtain a precipitate.

[0040] 1.5. After...

Embodiment 2

[0049] Embodiment 2 utilizes fungal polysaccharide to improve the method for polysaccharide content of ganoderma mycelia

[0050]The liquid fermentation of Ganoderma lucidum was carried out with reference to the method described in Example 1, the only difference being that: the activated Aspergillus niger strain was inoculated in step 1, and the Aspergillus niger polysaccharide was prepared, and the polysaccharide added to the liquid medium in the step 2 was black Aspergillus polysaccharide.

Embodiment 3

[0051] Embodiment 3 utilizes fungal polysaccharide to improve the method for polysaccharide content of Ganoderma lucidum mycelia

[0052] The liquid fermentation of Ganoderma lucidum was carried out with reference to the method described in Example 1, the only difference being that the activated Fusarium oxysporum strain was inoculated in step 1, and the Fusarium oxysporum polysaccharide was prepared, and the step 2 was added to the liquid medium The polysaccharide is Fusarium oxysporum polysaccharide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com