Polyspirofluorene containing hole transport group on side chain and preparation method and application thereof

A hole-transporting group, polyspirofluorene technology, used in semiconductor/solid-state device manufacturing, photovoltaic power generation, electrical components, etc., can solve the problems of device performance degradation, unfavorable PLED, damage to interface surface morphology, etc., and achieve low startup. Voltage, Effects of High Device Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

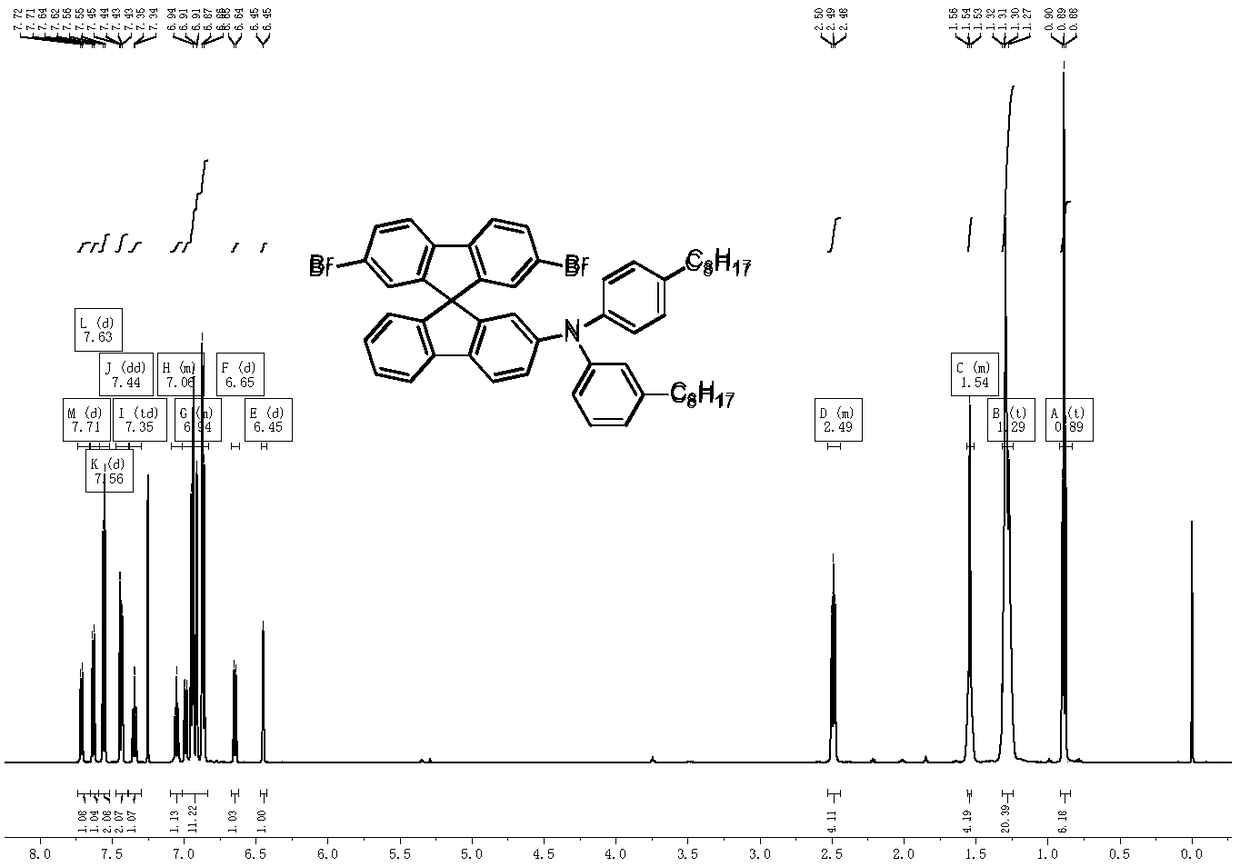

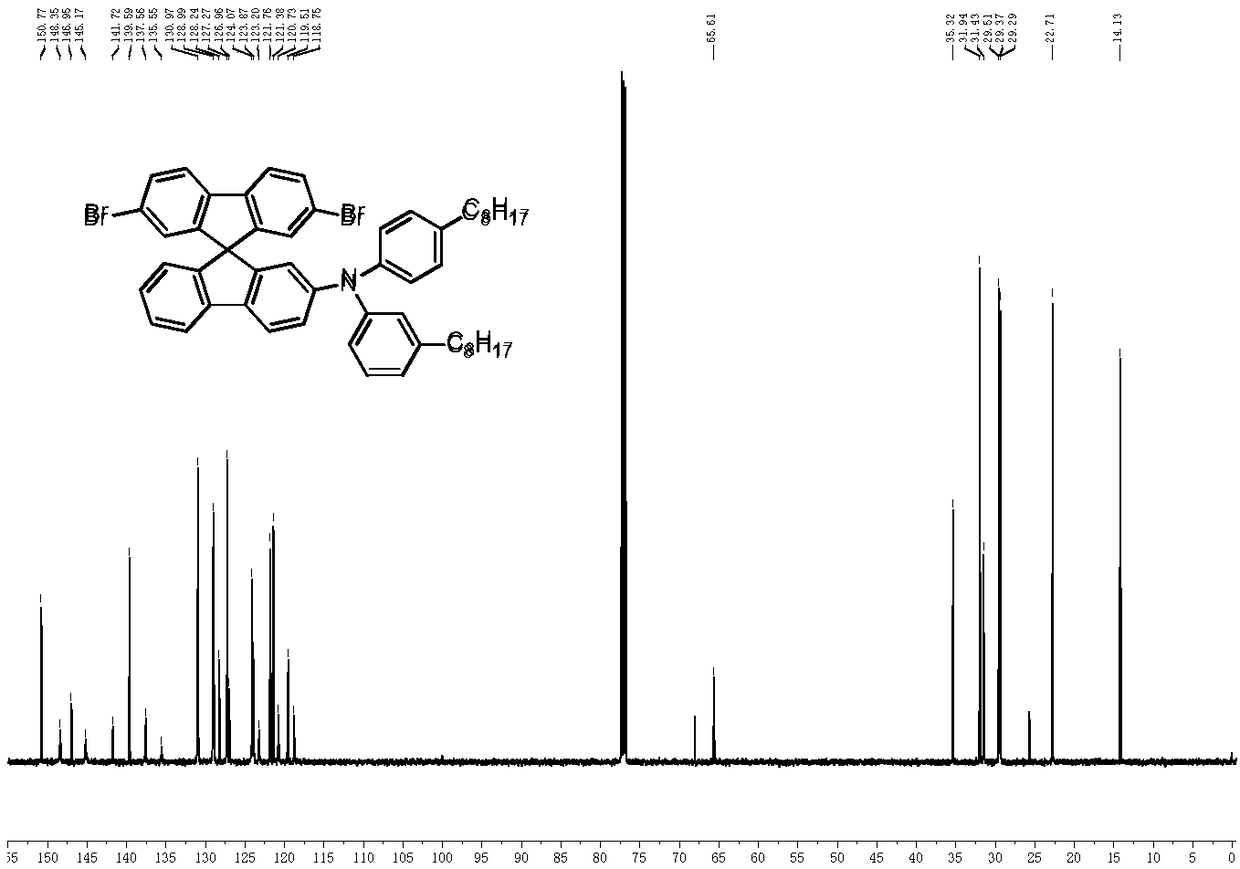

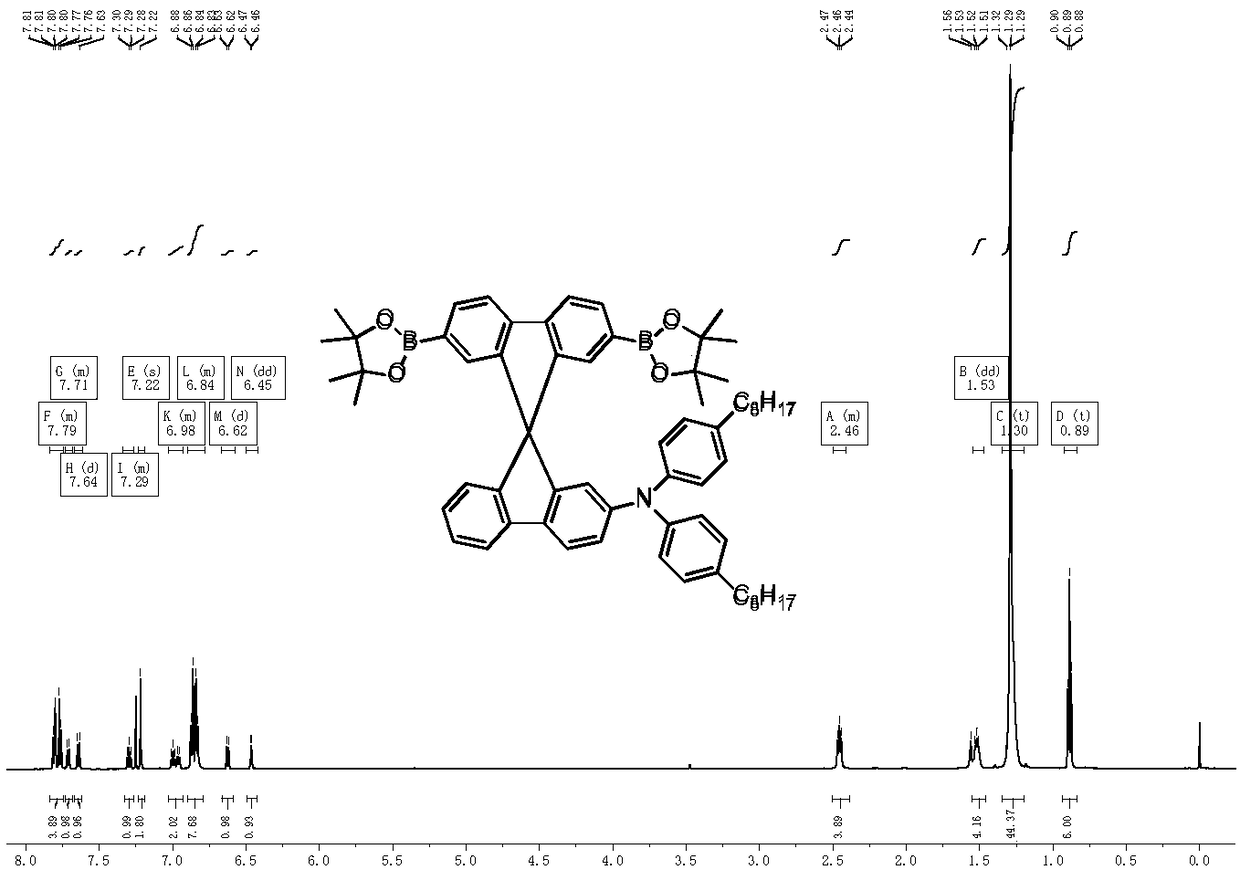

[0035] This embodiment provides a side chain containing polyspirofluorene P(C 8 The preparation method of TPA-SF).

[0036] (1) Preparation of 4-bromo-N,N-di(4-octylphenyl)aniline

[0037] Weigh 1-iodo-4-N-octylbenzene (22g, 70mmol), 4-bromoaniline (5.16g, 30mmol), 1,10-phenanthroline (0.632g, 3.5mmol), cuprous iodide ( 0.636g, 3.5mmol), potassium hydroxide (0.7mol, 39.2g) in a 250ml single-necked bottle, then add 84ml xylene and 56ml toluene. Under the protection of freezing liquid (absolute ethanol at about -40°C), the argon gas was changed three times, heated to 135°C, and refluxed for 24 hours. Cool down to room temperature, spread a layer of silica gel on a sand core funnel for suction filtration, and wash the filter cake three times with dichloromethane. Spin dry, pump dry, weigh, dissolve with dichloromethane, add 1 to 2 times of silica gel, spin dry, purify by silica gel chromatography, spin dry, pump dry, finally get 6.8g of colorless liquid product, yield = 41%. ...

Embodiment 2

[0069] This embodiment provides a method for preparing polyspirofluorene sPF whose side chain does not contain hole transport groups.

[0070] (1) Preparation of 2,7-dibromo-2'-(2-ethylhexyloxy)-9,9'-spirobifluorene

[0071] Weigh 2-bromo-4'-((2-ethylhexyl)oxy)-1,1'-biphenyl (4.33g, 12mmol) in a 250ml three-necked flask, change argon three times, inject 150ml of dried THF was dissolved, cooled to -78°C, and n-butyl lithium (7.5ml, 18.75mmol) was injected into the constant pressure dropping funnel, and added dropwise slowly. Reacted at -78°C for 2h, weighed dibromofluorenone (4.1g, 12mmol), quickly added it into a three-neck flask, reacted at about -60°C for 2h, raised the temperature naturally, and stirred overnight. The next day, 10 g of ammonium chloride and 100 ml of water were added to the reaction solution to quench it. Extracted three times with ethyl acetate, combined organic layers, washed with water, washed with saturated brine, dried over anhydrous magnesium sulfat...

Embodiment 3

[0087] This embodiment provides the polyspirofluorene P(C 8 TPA-SF) and the comparative application of the sPF prepared in Example 2 without a hole-transporting group in the side chain in an electroluminescent device.

[0088] Based on polymer P(C 8 Preparation of electroluminescent devices of TPA-SF) and sPF

[0089] The pre-made indium tin oxide (ITO) glass with a square resistance of ≤12Ω / mouth is ultrasonically cleaned with deionized water, acetone, detergent, deionized water and isopropanol for 20 minutes, and placed in an oven at 80°C. , dry overnight. Treat with oxygen plasma for 4 minutes before use; Spin-coat PEDOT:PSS on ITO, spin-coating speed is 3000r, 30s, and the thickness is about 40nm. After the spin coating is finished, place it on a heating platform at 120° C. for annealing for 20 min to remove the solvent; then add 16 mg / ml of P(C 8 TPA-SF) xylene solution, or a mixed solution of 16mg / ml sPF xylene and tetrahydrofuran, spin-coated on PEDOT:PSS, with a th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| luminance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com