Method for reducing loss of hot bending glass die and equipment thereof

A glass mold and mold technology, applied in glass manufacturing equipment, glass molding, glass re-molding and other directions, can solve the problems of destroying the structure of graphite molds, expensive graphite molds, affecting the cost of curved glass, etc. The effect of longevity and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

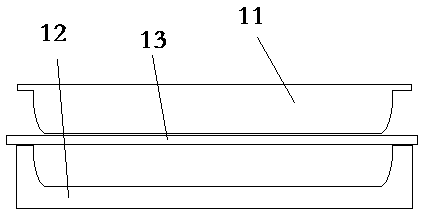

[0048] In this embodiment, nitrogen is used as the protective gas, high-pressure gas flushing is used for the first replacement of external air, and the second replacement of air inside the mold 1 is carried out by sending it into the equipment for vacuuming and then using nitrogen.

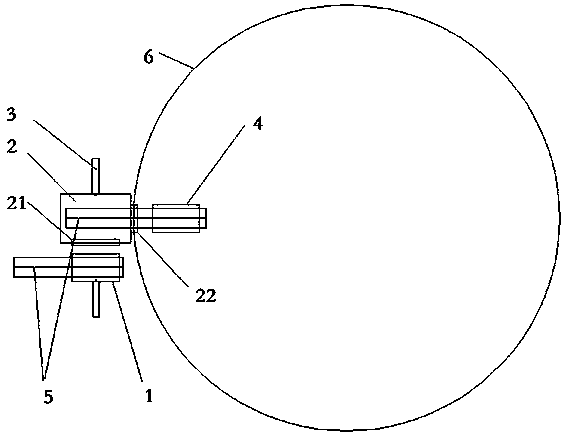

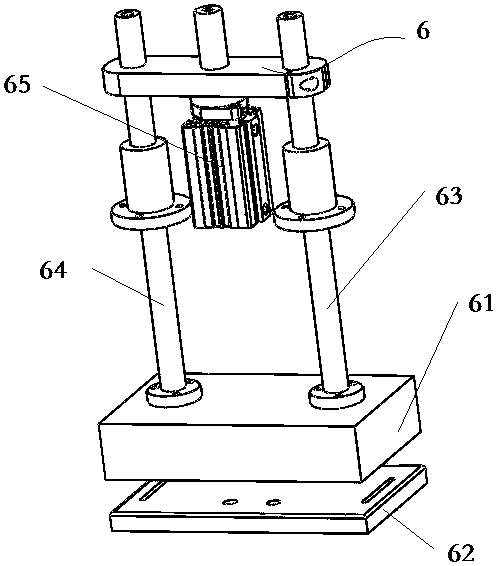

[0049] as attached figure 2 As shown, the mold 1 passes through the bottom bracket 62 on the track 5 for transportation, and when it is transmitted laterally, it is pushed laterally by the push cylinder 3 .

[0050] The sealed space 2 adopts a sealed glass cover, and a first automatic door 21 is arranged on one side of the sealed glass cover, which can be opened or closed according to program control. The sealed glass cover and the equipment are airtightly connected, and a The second automatic door 22 can also be controlled to open or close according to the program.

[0051] The processing equipment 4 is a high-temperature heating equipment, and the interior of the processing equipment 4 is a p...

Embodiment 2

[0059] In this embodiment, the difference from Embodiment 1 is that the vacuum extraction equipment is not installed in the processing equipment 4, but is installed in the enclosed space 2, and in addition, the enclosed space 2 is also provided with another machine to extract the enclosed space 2. Vacuum equipment.

[0060] After the mold 1 to be processed is sent into the closed space 2, the second automatic door 22 is not opened, but the vacuuming equipment of the closed space 2 is started to vacuumize the whole closed space 2 and inject nitrogen gas. Then vacuumize the inside of the mold 1 and inject nitrogen gas. After vacuuming twice, the second automatic door 22 is opened again, and the mold 1 is sent into the processing equipment 4 . The embodiments of the present invention have been described in detail above in conjunction with the accompanying drawings, but the present invention is not limited to the above-mentioned embodiments. kind of change.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com