Method for treating high-nitrogen and low-carbon rare earth ore mining wastewater step by step by using microalgae and activated sludge

A technology of activated sludge and mining wastewater, applied in mining wastewater treatment, water/sludge/sewage treatment, biological water/sewage treatment, etc., can solve the problems of lack of treatment methods, high cost, poor feasibility, etc. The effect of low speed, equipment requirements, and high economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1 The preparation method of the enriched microalgae of Scenedesmus and Chlorella spp., the steps are as follows:

[0034] 1) Take 1L of mining wastewater from Zudong Rare Earth Mine in Longnan, Ganzhou City, Jiangxi Province, and use dipotassium hydrogen phosphate to adjust the nitrogen-to-phosphorus ratio of the rare earth mining wastewater to 5:1. The wastewater is directly inoculated from the vicinity of Chaoyang Bridge on the Ganjiang River without disinfection. 0.5mL of river water in the water body was placed in the corridor of the experimental building Q building of Nanchang Hangkong University in Jiangxi Province for 30 days at a temperature of 30°C, a humidity of 60%, and natural light conditions to obtain domesticated microalgae. The samples were submitted to the Freshwater Algae Species Bank of the Typical Culture Collection Committee of the Chinese Academy of Sciences for identification. The identification report showed that the algae contained in ...

Embodiment 2

[0038] 1) Dicalcium hydrogen phosphate is used to adjust the nitrogen-phosphorus ratio of rare earth mining wastewater to 0.5:2 to obtain wastewater to be purified;

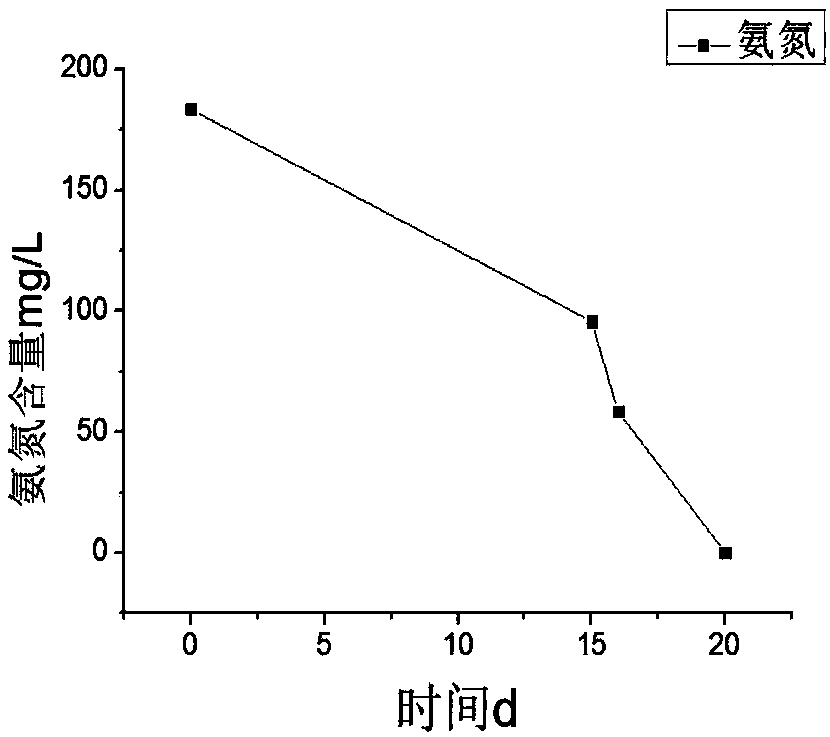

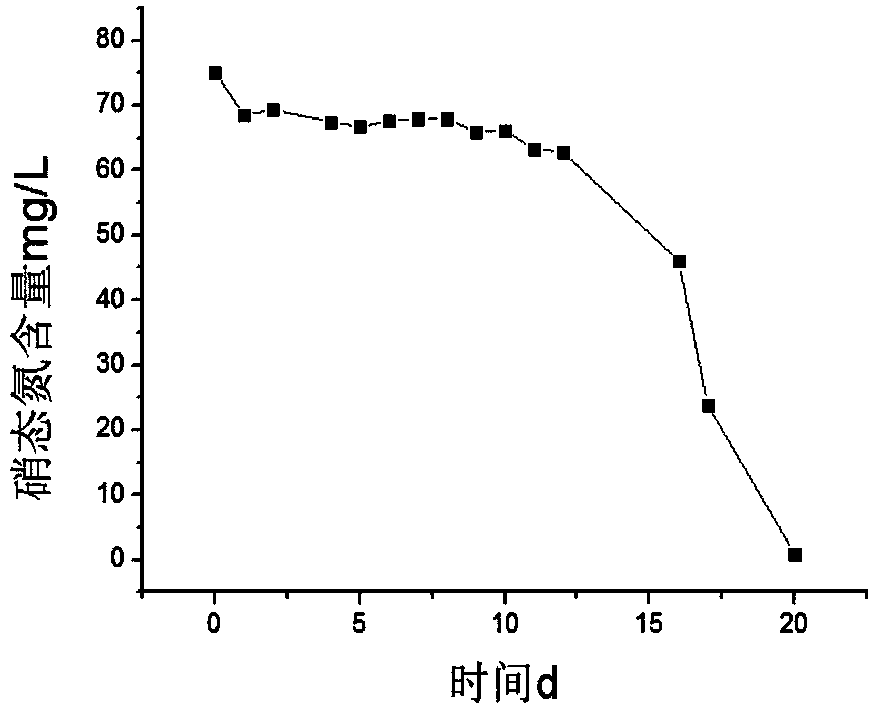

[0039] 2) Take the enriched microalgae solution of Scenedesmus and Chlorella parasitic prepared in Example 1 with a dry weight of 1.5 g and add it to 300 mL of wastewater to be purified. Perform 22 days of preliminary purification treatment under light conditions, and obtain preliminary purified water after separation of algal water;

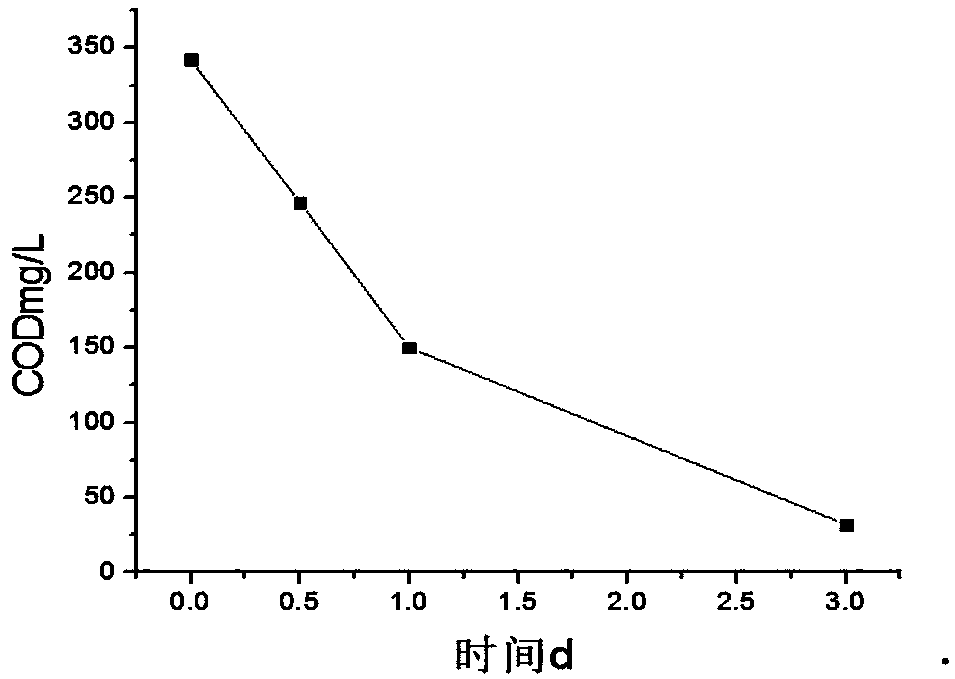

[0040] 3) Add 35mL of activated sludge to the preliminary purified water in step 2), put the Erlenmeyer flask into a shaker, and perform another purification treatment for 3 days under the conditions of 26° C. and 500 rpm to obtain purified water.

Embodiment 3

[0042] 1) Use potassium dihydrogen phosphate to adjust the nitrogen-phosphorus ratio of the rare earth mining wastewater to 1:3 to obtain the wastewater to be purified;

[0043] 2) Take the enriched microalgae solution containing Scenedesmus and Chlorella parasitic prepared in Example 1 with a dry weight of 1 g and add it to 300 mL of wastewater to be purified. Perform 20d preliminary purification treatment under the same conditions, and obtain preliminary purified water after separation of algae water;

[0044] 3) Add 25mL of activated sludge to the preliminary purified water in step 2), put the Erlenmeyer flask into a shaker, and perform another purification treatment for 4 days under the conditions of 25°C and 700 rpm to obtain purified water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com