Workpiece automatic clearing device

An automatic cleaning and workpiece technology, applied in the field of additive manufacturing, can solve problems affecting processing quality, dust pollution damage of operators, serious production environment pollution, etc., to achieve thorough cleaning effect, outstanding economy and high cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

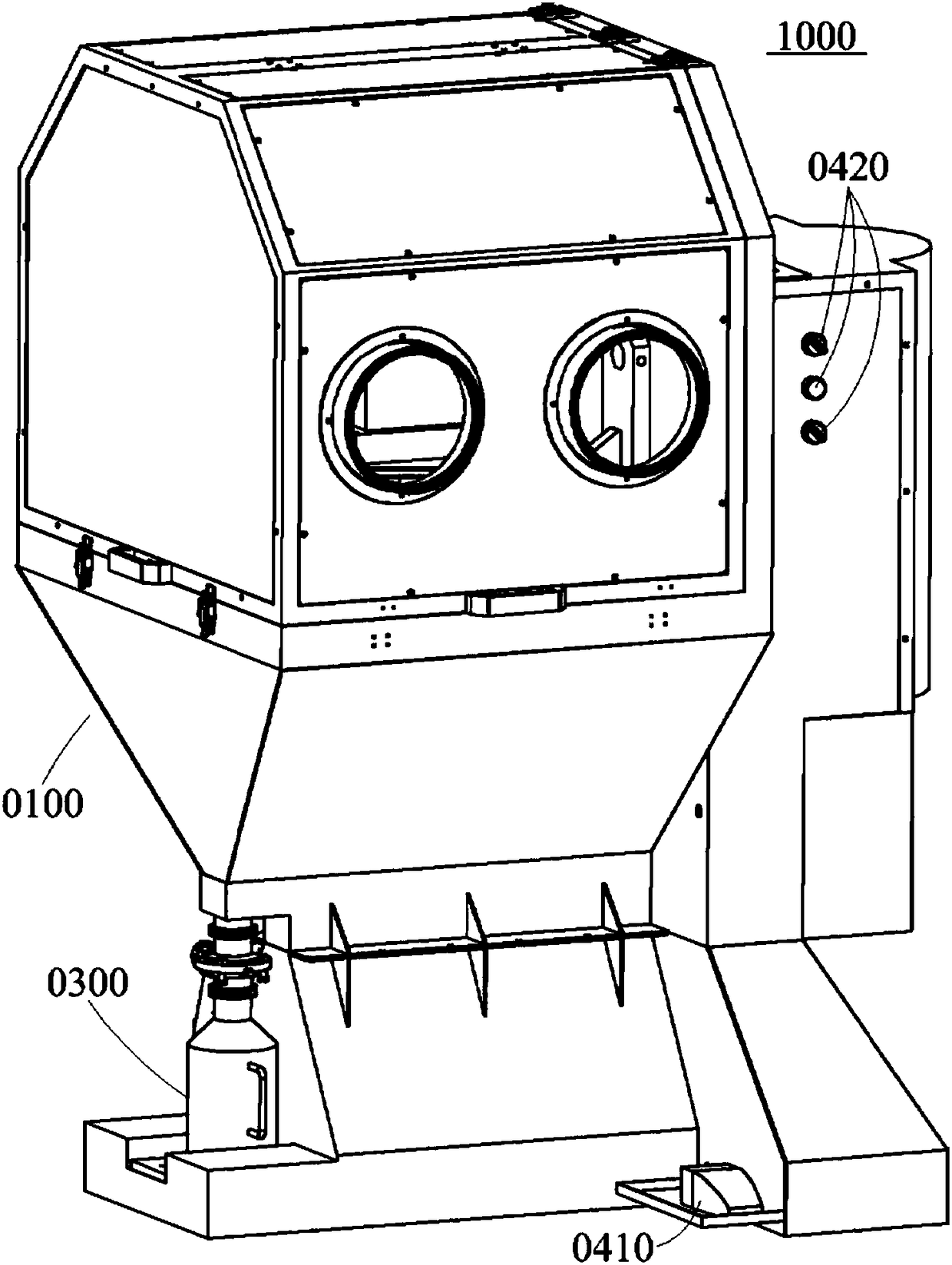

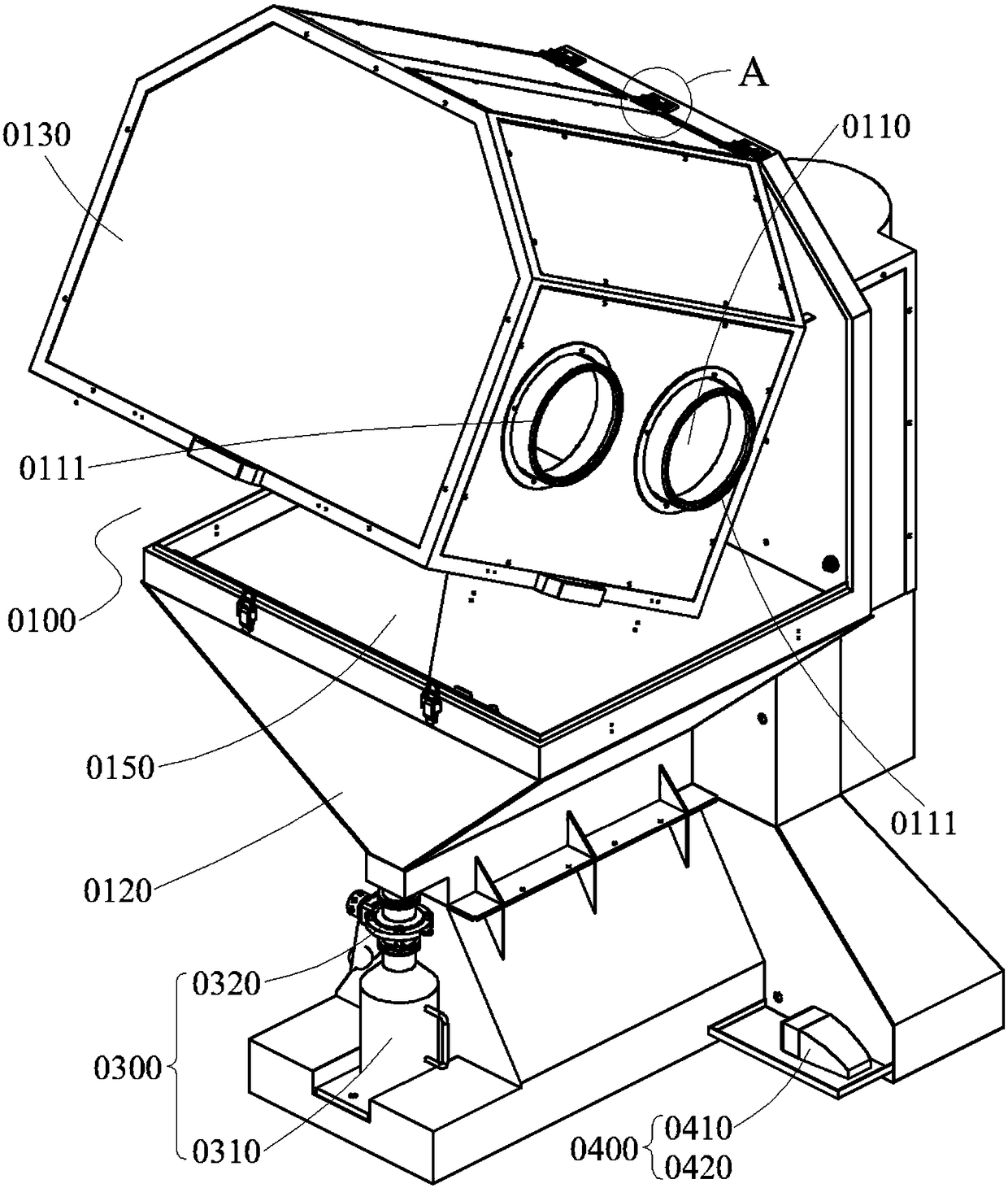

[0037] Please refer to Figure 1~2 and Figure 7-8 , this embodiment discloses an automatic workpiece cleaning device 1000, including a glove box 0100, a purging device 0200, and a collecting device 0300, which are used to realize multi-directional automatic cleaning and powder material recovery in an inert gas environment, with high efficiency and The safety is good, the powder can be recovered and recycled, and the economic advantages are obvious.

[0038] Please refer to Figure 1~6 , the glove box 0100 is the main component of the automatic workpiece cleaning equipment 1000, which has the function of isolating the inside and outside and bearing the main load. The glove box 0100 can be made of different materials, such as metal (steel, aluminum alloy, etc.), polymer material (resin), glass, etc., to maintain stable physical and chemical properties during the cleaning process.

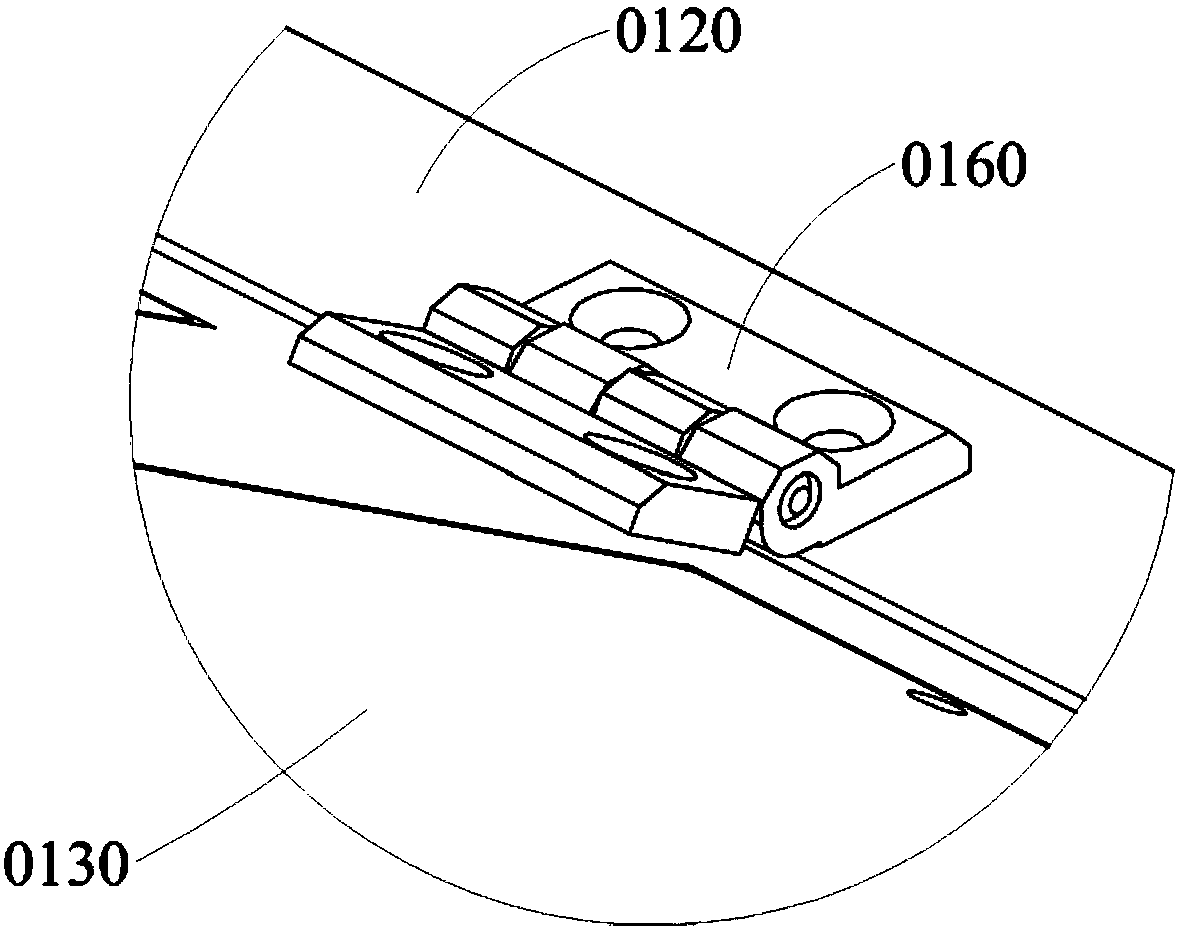

[0039] A dust-free operation chamber 0110 is provided inside the glove box 0100, and the dust-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com