Novel lightweight electromagnetic self-piercing riveting gun

A lightweight, self-piercing riveting technology, which is applied in the field of electromagnetic riveting equipment and riveting equipment, can solve the problems of seldom research on portable electromagnetic self-piercing riveting guns, riveting recoil cannot be offset, and the structure of the riveting system is complex, etc., to achieve shock absorption effect Obvious effect of increased forming force and low control cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

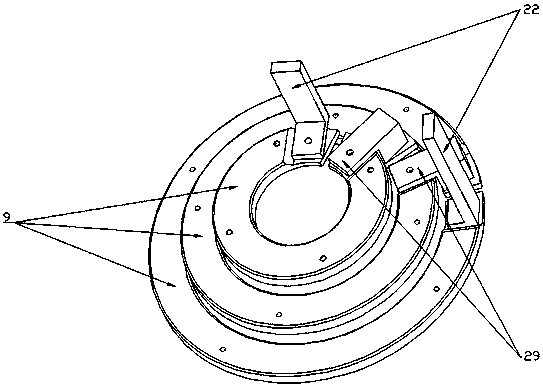

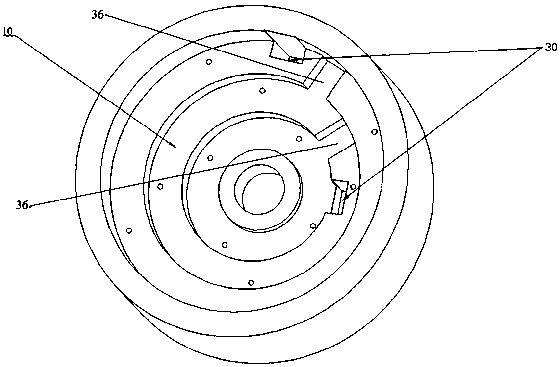

[0031] Depend on figure 1 As shown, a new lightweight electromagnetic self-piercing riveting gun includes a punch 1, an amplifier 5, a driver plate carrier 37, a driver plate 7, a shell 8, a coil 9, a coil carrier 10, a rubber cushion 11, and a fixing plate 12. Guide rod sleeve 13, buffer block 14, guide rod 15, spring upper pressure block 16, connection seat 18, return spring 19, guide cylinder 20, spring lower pressure block 21, electromagnetic equipment 28, connector 29, terminal 22. Compression screw 17 and die 3, the coil carrier 10 is fixedly installed on the bottom of the fixed plate 12, the rubber buffer pad 11 is fixedly installed on the fixed plate 12, and the buffer block 14 is fixedly installed on the rubber buffer pad 11, the buffer block 14 can adopt No. 45 steel material. Depend on Figure 12 As shown, the spring lower pressure block 21 is fixedly installed on the fixed plate 12, by Figure 13 As shown, the guide cylinder 20 is fixedly installed on the spring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com