Double-layer steel bar mesh machining device

A steel mesh sheet and processing device technology, applied to wire processing, wire mesh, and other household appliances, can solve problems such as large welding quality constraints, large fluctuations in steel bar forming quality, and unstable welding quality, and achieve a reduction in slope. The difficulty of bundling and installing surface steel bars, reducing the number of operators on the warehouse surface, and reducing the effect of safety production risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

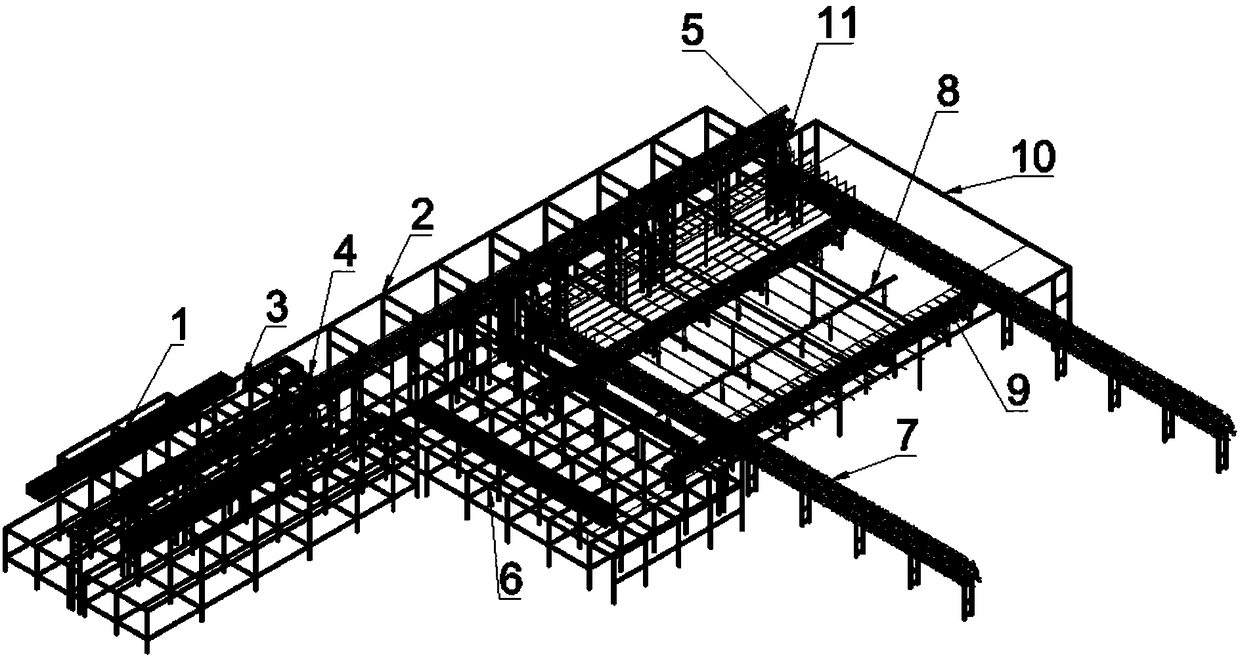

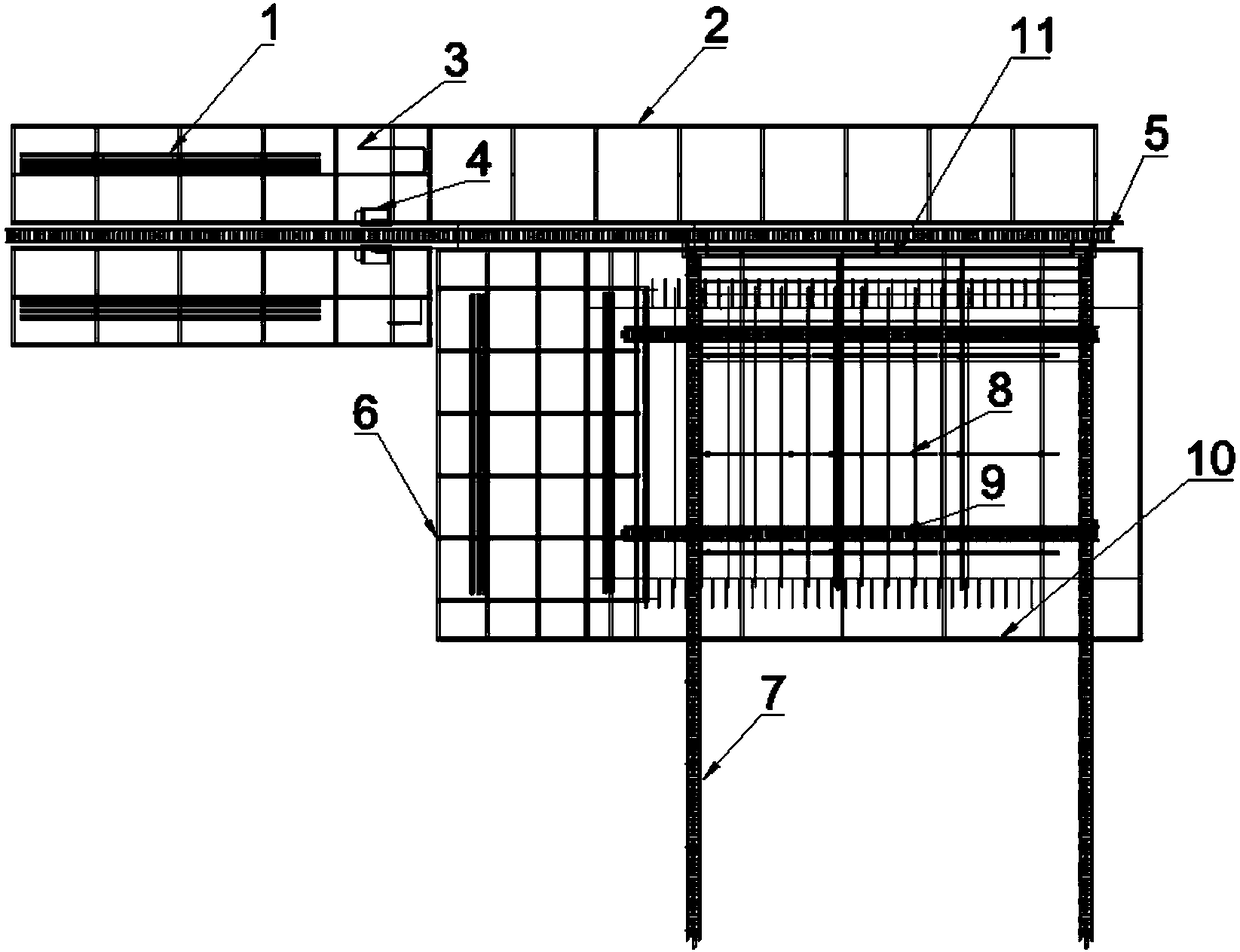

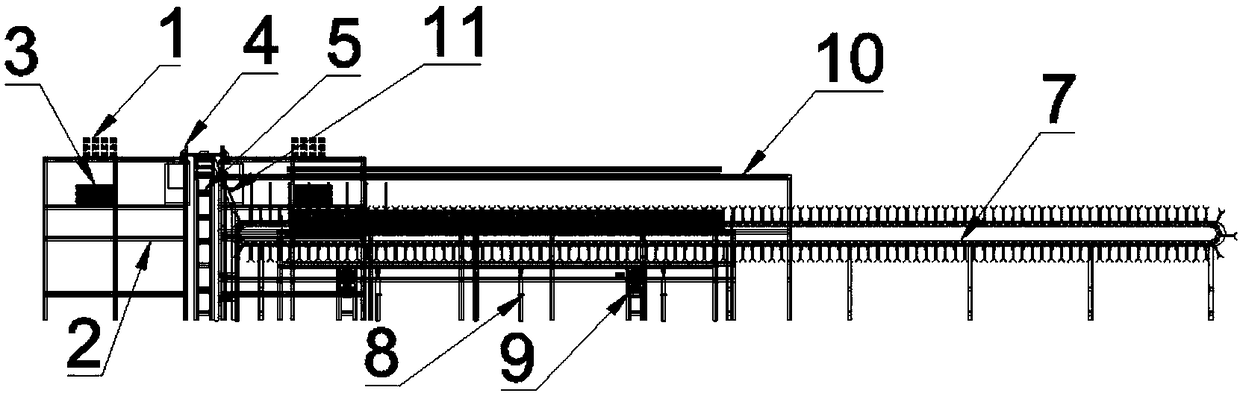

[0032] Such as Figure 1-10 As shown, a double-layer reinforced mesh processing device includes a stirrup conveying device 5, a steel bar erecting device 23 and a flash butt welding machine 4 are arranged at a corresponding position at one end, and a transverse conveying device 7 perpendicular to it is provided at a corresponding position at the other end The stirrup delivery device 5 is provided with a first sliding device 11 for erecting the stirrups from the plane to the vertical direction near the end of the horizontal delivery device 7; The force bar is lifted to the force bar lifting device 8 under the stirrup; it also includes a stacking and distribution platform 10 arranged above the corresponding position of the transverse conveying device 7 for distributing the upper layer of force bar on the upper surface of the stirrup; The tendon ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com