Porous volatile organic compound absorbing calcium carbonate-kaolin composite material and preparation method thereof

A technology of organic volatiles and composite materials, which is applied in separation methods, chemical instruments and methods, and air quality improvement, etc., can solve the problems of cumbersome preparation methods, poor calcium carbonate performance, and inability to effectively control heating conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

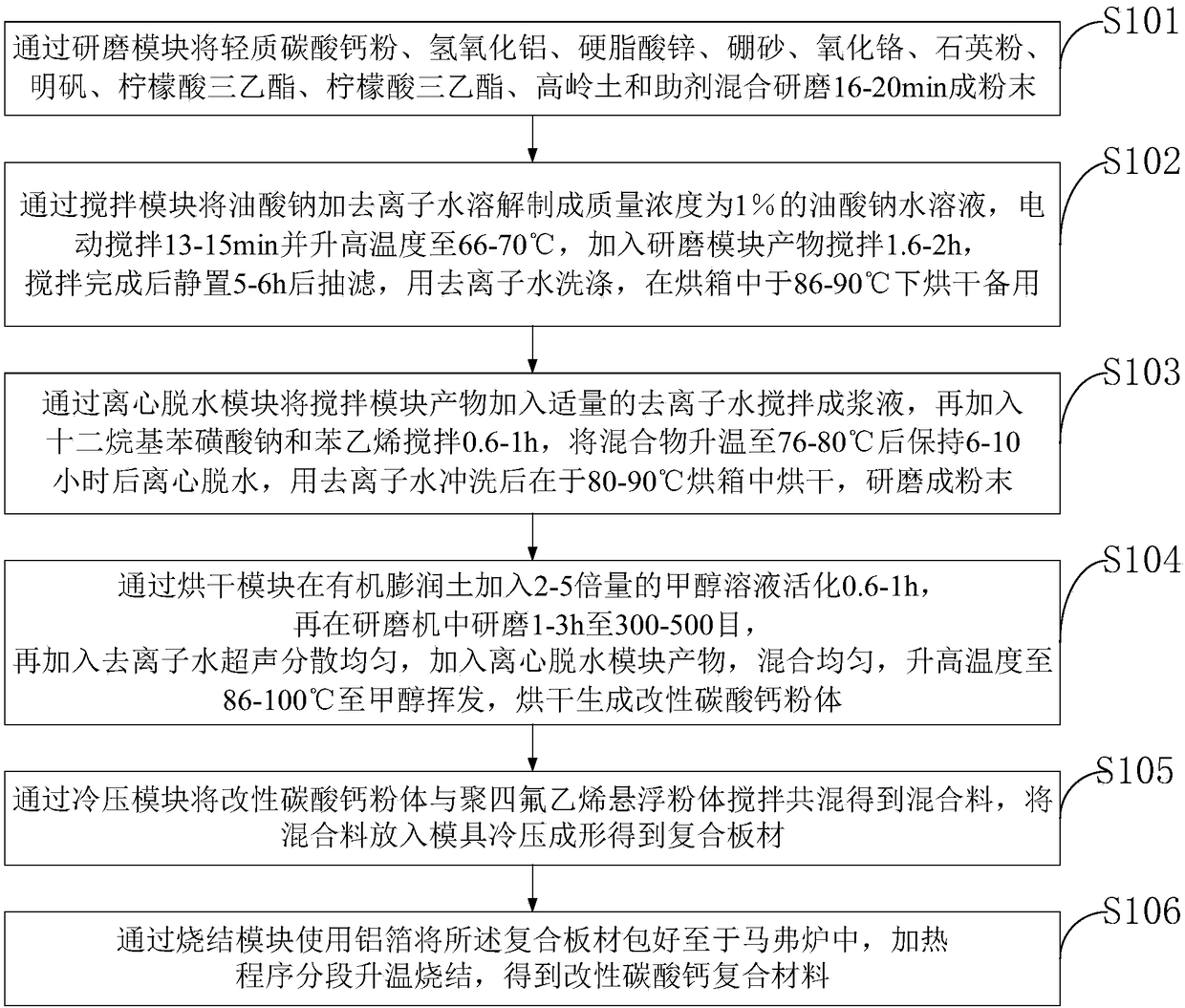

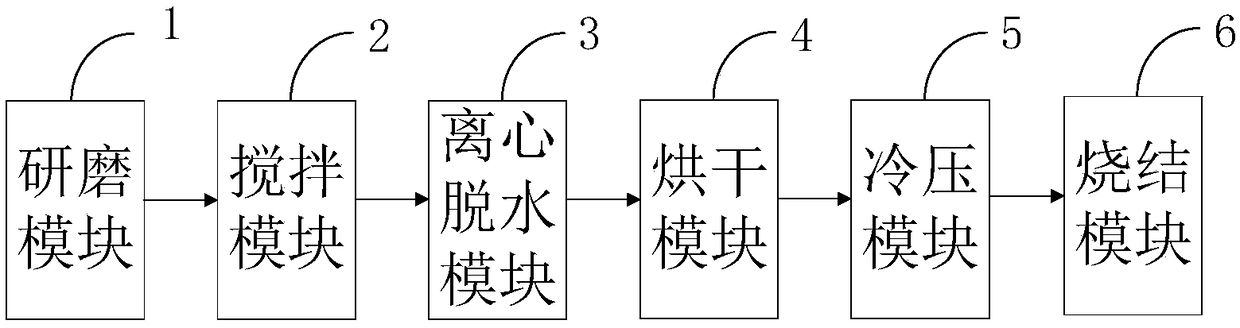

[0066] like figure 1 Shown, the preparation method of a kind of multi-void adsorption organic volatile matter calcium carbonate kaolin composite material provided by the invention comprises the following steps:

[0067] S101, through the grinding module, light calcium carbonate powder, aluminum hydroxide, zinc stearate, borax, chromium oxide, quartz powder, alum, triethyl citrate, triethyl citrate, kaolin and auxiliary agents are mixed and ground 16 -20min into powder;

[0068] S102, dissolving sodium oleate and deionized water through the stirring module to make a sodium oleate aqueous solution with a mass concentration of 1%, electric stirring for 13-15min and raising the temperature to 66-70°C, adding the product in the grinding module and stirring for 1.6-2h After the stirring is completed, let it stand for 5-6 hours, then filter it with suction, wash it with deionized water, and dry it in an oven at 86-90°C for later use;

[0069] S103, add an appropriate amount of dei...

Embodiment 1

[0112] The multi-void adsorption organic volatile calcium carbonate kaolin composite material provided by the embodiments of the present invention is composed of:

[0113] 10 parts of light calcium carbonate powder, 10 parts of aluminum hydroxide, 5 parts of zinc stearate, 10 parts of borax, 5 parts of chromium oxide, 10 parts of quartz powder, 5 parts of alum, 5 parts of triethyl citrate, 5 parts of triethyl citrate, 5 parts of ethyl ester, 10 parts of kaolin, 5 parts of additives, 3 parts of sodium oleate, 3 parts of sodium dodecylbenzenesulfonate, 5 parts of styrene, 5 parts of organic bentonite and 5 parts of polytetrafluoroethylene.

Embodiment 2

[0115] The multi-void adsorption organic volatile calcium carbonate kaolin composite material provided by the embodiments of the present invention is composed of:

[0116] 15 parts of light calcium carbonate powder, 15 parts of aluminum hydroxide, 10 parts of zinc stearate, 15 parts of borax, 8 parts of chromium oxide, 15 parts of quartz powder, 6 parts of alum, 15 parts of triethyl citrate, triethyl citrate 15 parts of ethyl ester, 15 parts of kaolin, 7 parts of additives, 5 parts of sodium oleate, 5 parts of sodium dodecylbenzenesulfonate, 10 parts of styrene, 10 parts of organic bentonite and 10 parts of polytetrafluoroethylene.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com