Konjac glucomannan-liposome composite nano food delivery system and preparation method and application thereof

A technology of konjac glucomannan and delivery system, which is applied in food science and other fields, and can solve the problems of poor stability of the carrier system and difficulty in co-loading food functional factors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

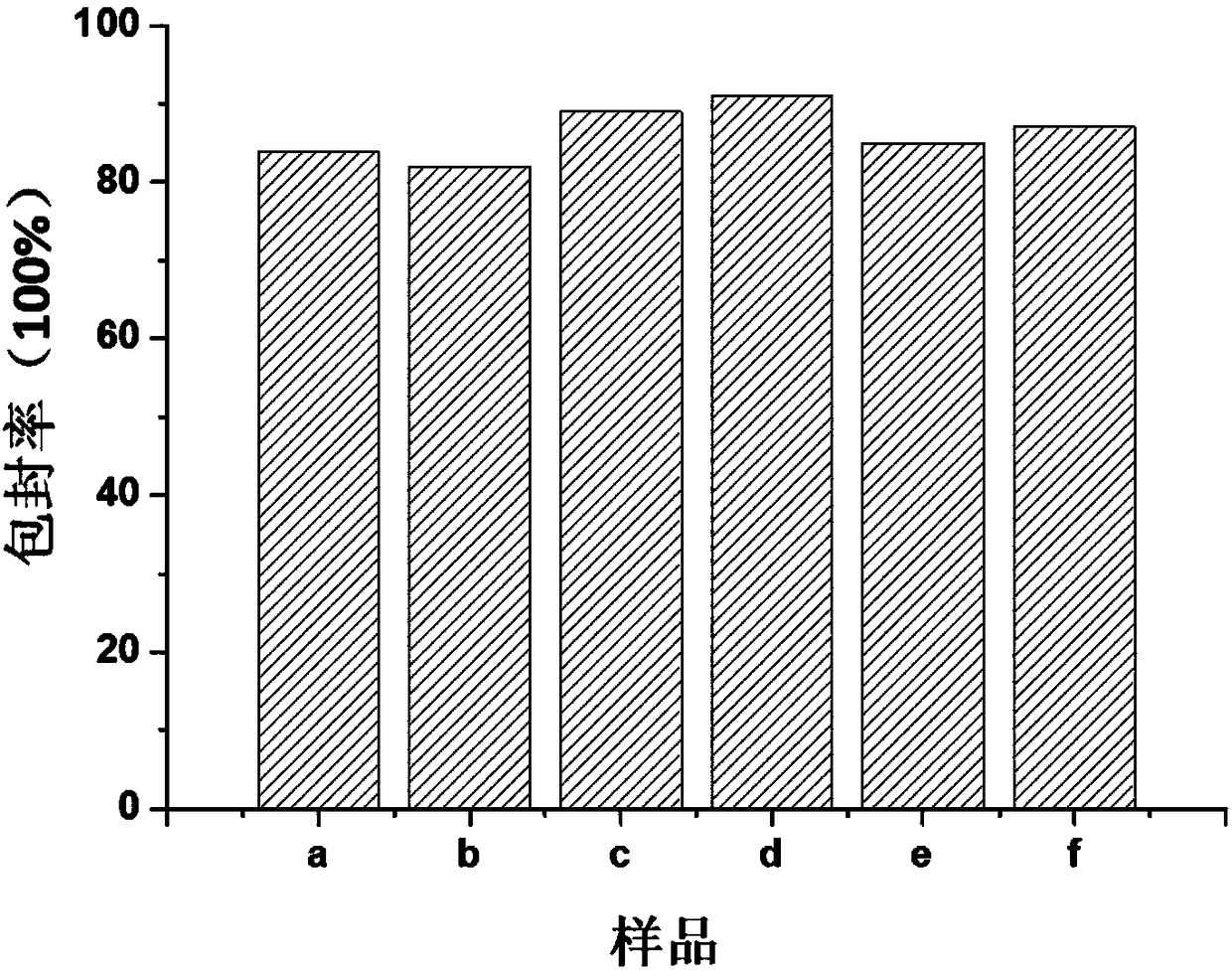

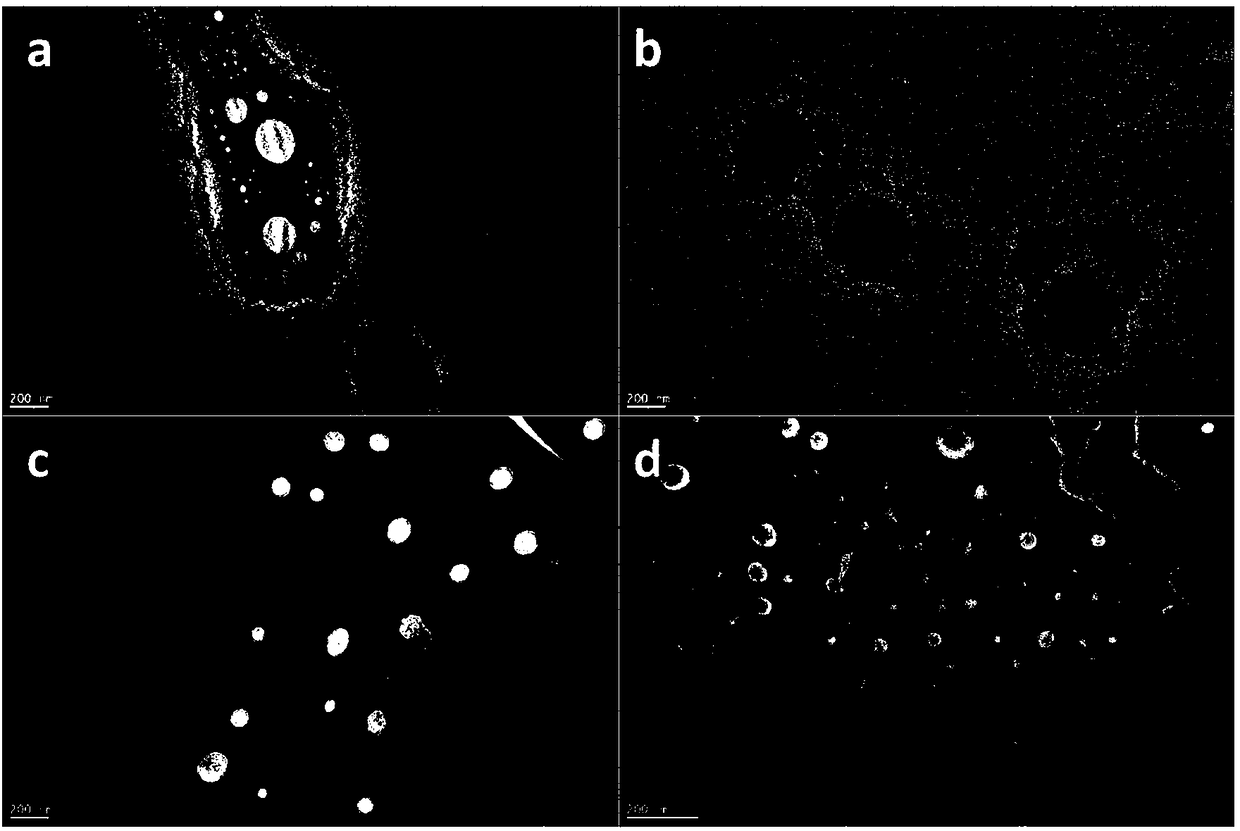

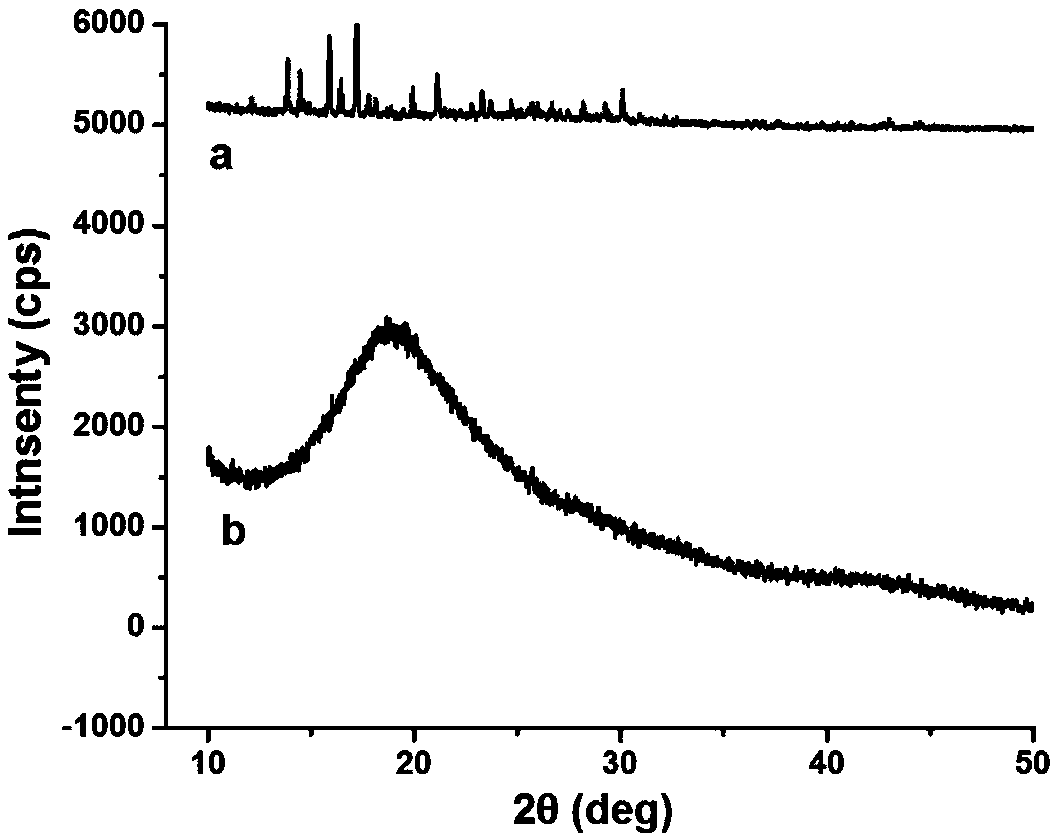

Embodiment 1

[0094] 1) Weigh 1 gram of KGM and disperse it in 500 mL of double distilled water, mechanically stir and swell for 12 hours at room temperature; obtain KGM1 dispersion;

[0095] 2) Weigh 0.4 g of sodium periodate and dissolve it in 20 mL of double-distilled water, add it dropwise to KGM dispersion 1, stir and react at room temperature in the dark for 48 hours; concentrate the reaction solution at 40°C to 100 mL under reduced pressure, filter, and use 3500 MW for dialysis The bag was dialyzed in double distilled water for 7 days, and then the dialysate was freeze-dried for 48 hours to obtain white DAK1 powder.

Embodiment 2

[0097] 1) Weigh 1 gram of KGM and disperse it in 500 mL of double-distilled water, mechanically stir and swell for 12 hours at room temperature to obtain a KGM2 dispersion;

[0098] 2) Weigh 0.6 g of sodium periodate and dissolve it in 30 mL of double-distilled water, add it dropwise into KGM dispersion 2, and stir for 36 hours at room temperature in the dark. The reaction solution was concentrated under reduced pressure at 45°C to 100 mL, filtered, dialyzed in double distilled water for 7 days using a 3500 MW dialysis bag, and then the dialysate was freeze-dried for 48 hours to obtain white DAK2 powder.

Embodiment 3

[0100] 1) Weigh 1 gram of KGM and disperse it in 500 mL of double-distilled water, mechanically stir and swell for 12 hours at room temperature to obtain a KGM3 dispersion;

[0101] 2) Weigh 0.8 g of sodium periodate and dissolve it in 40 mL of double-distilled water, add it dropwise into KGM dispersion 3, and stir for 24 hours at room temperature in the dark. The reaction solution was concentrated under reduced pressure at 50°C to 100 mL, filtered, dialyzed in double distilled water for 7 days using a 3500 MW dialysis bag, and then the dialysate was freeze-dried for 48 hours to obtain white DAK3 powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com