Method for detecting residual iron content in degreasing agent

A detection method and degreasing agent technology, applied in the direction of material excitation analysis, thermal excitation analysis, etc., can solve the problem that the residual iron content of the degreasing agent cannot be accurately detected, and achieve the effect of high degree of automation, high accuracy, and guaranteed degreasing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

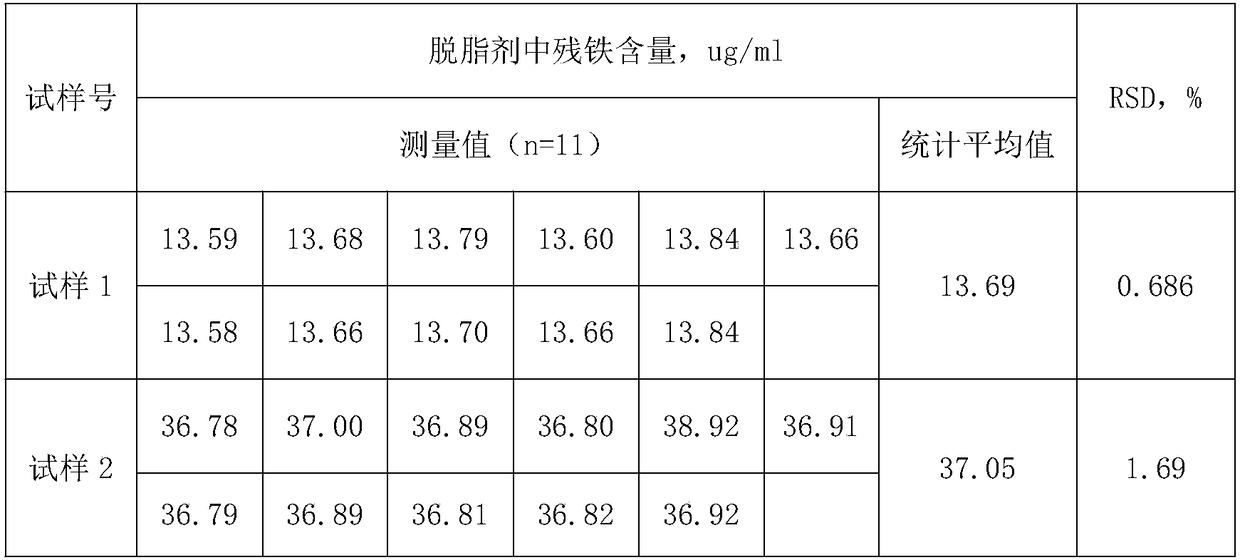

Examples

Embodiment Construction

[0017] A method for detecting residual iron content in a degreasing agent, comprising the following steps:

[0018] 1) Prepare the solution to be tested, pipette 10ml of the degreasing agent sample solution to be tested and place it in a 150ml Erlenmeyer flask, inject 5ml of hydrochloric acid solution with a volume concentration of 1:3 (excellent grade pure hydrochloric acid and deionized The water volume ratio is 1:3) the degreasing agent solution to be tested is acidified, and the degreasing agent solution to be tested after the acidification treatment is transferred to the 100ml volumetric flask, and the volume is fixed to the mark, and the solution to be tested is obtained after shaking up;

[0019] 2) measure the spectral intensity I of iron in the solution to be measured in step 1) when the wavelength is 239.562nm with the American thermoelectric company to produce the model as iCAP6300 inductively coupled plasma emission spectrometer Fe ;

[0020] 3) calculate the resi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com