Scale and corrosion inhibition microcapsule and preparation method thereof

A technology for scale and corrosion inhibition and microcapsules is applied in the field of scale and corrosion inhibition microcapsules and their preparation, which can solve the problems of poor control of dosage, eutrophication of water bodies, secondary environmental pollution, etc., and achieve excellent corrosion inhibition. Synergistic effect, lower disposal cost, easy biodegradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

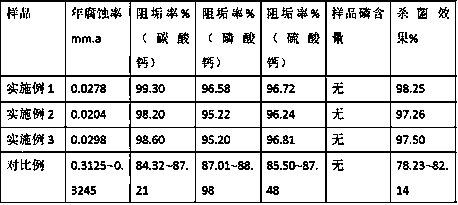

Examples

preparation example Construction

[0020] The preparation method of the polyaspartic acid complex: in parts by mass, take 6~10 parts of water, 3~5 parts of sodium hydroxide solution, mix and stir, and finally take 20~30 parts of polyaspartic acid, 15~20 parts 1 part of acrylic acid-hydroxyethyl acrylate copolymer, 13~18 parts of citric acid, 16~22 parts of ammonia water, mixed and stirred for 20~30min, and the temperature was kept at 30~35°C to obtain a modified polyaspartic acid compound;

[0021] The preparation method of the corrosion-inhibiting compound: in parts by mass, at 20-25°C, take 40-50 parts of polyacrylamide, 15-23 parts of 2,3-diaminonaphthalene, 8-13 parts of hydrogen bromide, 7 ~10 parts of OP-15, 12~15 parts of sodium secondary alkyl sulfonate, 10~15 parts of water are mixed and stirred, and the temperature is adjusted to 40~45°C to obtain the corrosion inhibition compound;

[0022] Composite emulsifier: in parts by mass, take 20-25 parts of polyoxyethylene oleate, 10-14 parts of polyoxyethyle...

Embodiment 1

[0029] The preparation method of the polyaspartic acid complex: in parts by mass, 6 parts of water and 3 parts of sodium hydroxide solution are mixed and stirred, and then 20 parts of polyaspartic acid and 15 parts of acrylic acid-hydroxyethyl acrylate are copolymerized Compound, 13 parts of citric acid, and 16 parts of ammonia water were mixed and stirred for 20 minutes, and the temperature was kept at 30°C to obtain a modified polyaspartic acid complex;

[0030] The preparation method of the corrosion-inhibiting compound: in parts by mass, at 20°C, take 40 parts of polyacrylamide, 15 parts of 2,3-diaminonaphthalene, 8 parts of hydrogen bromide, 7 parts of OP-15, 12 parts of secondary Sodium alkylsulfonate and 10 parts of water were mixed and stirred, and the temperature was adjusted to 40°C to obtain a corrosion-inhibiting compound;

[0031] Composite emulsifier: in parts by mass, 20 parts of polyoxyethylene oleate, 10 parts of polyoxyethylene ether, and 20 parts of water ar...

Embodiment 2

[0038]The preparation method of the polyaspartic acid complex: in parts by mass, 10 parts of water and 5 parts of sodium hydroxide solution are mixed and stirred, and then 30 parts of polyaspartic acid and 20 parts of acrylic acid-hydroxyethyl acrylate are copolymerized Compound, 18 parts of citric acid, 22 parts of ammonia water, mixed and stirred for 30 minutes, and the temperature was kept at 35°C to obtain a modified polyaspartic acid complex;

[0039] The preparation method of the corrosion inhibition compound: in parts by mass, at 25°C, take 50 parts of polyacrylamide, 23 parts of 2,3-diaminonaphthalene, 13 parts of hydrogen bromide, 10 parts of OP-15, 15 parts of secondary Sodium alkyl sulfonate and 15 parts of water were mixed and stirred, and the temperature was adjusted to 45°C to obtain a corrosion-inhibiting compound;

[0040] Composite emulsifier: in parts by mass, 25 parts of polyoxyethylene oleate, 14 parts of polyoxyethylene ether, and 30 parts of water are mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com