A catalyst and a method for preparing light olefins by direct carbon monoxide hydrogenation conversion

A technology of catalysts and oxides, applied in the direction of hydrocarbon production from carbon oxides, heterogeneous catalyst chemical elements, catalysts, etc., to achieve low methane selectivity, good application prospects, and the effect of product separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1. Preparation of Catalyst A Component

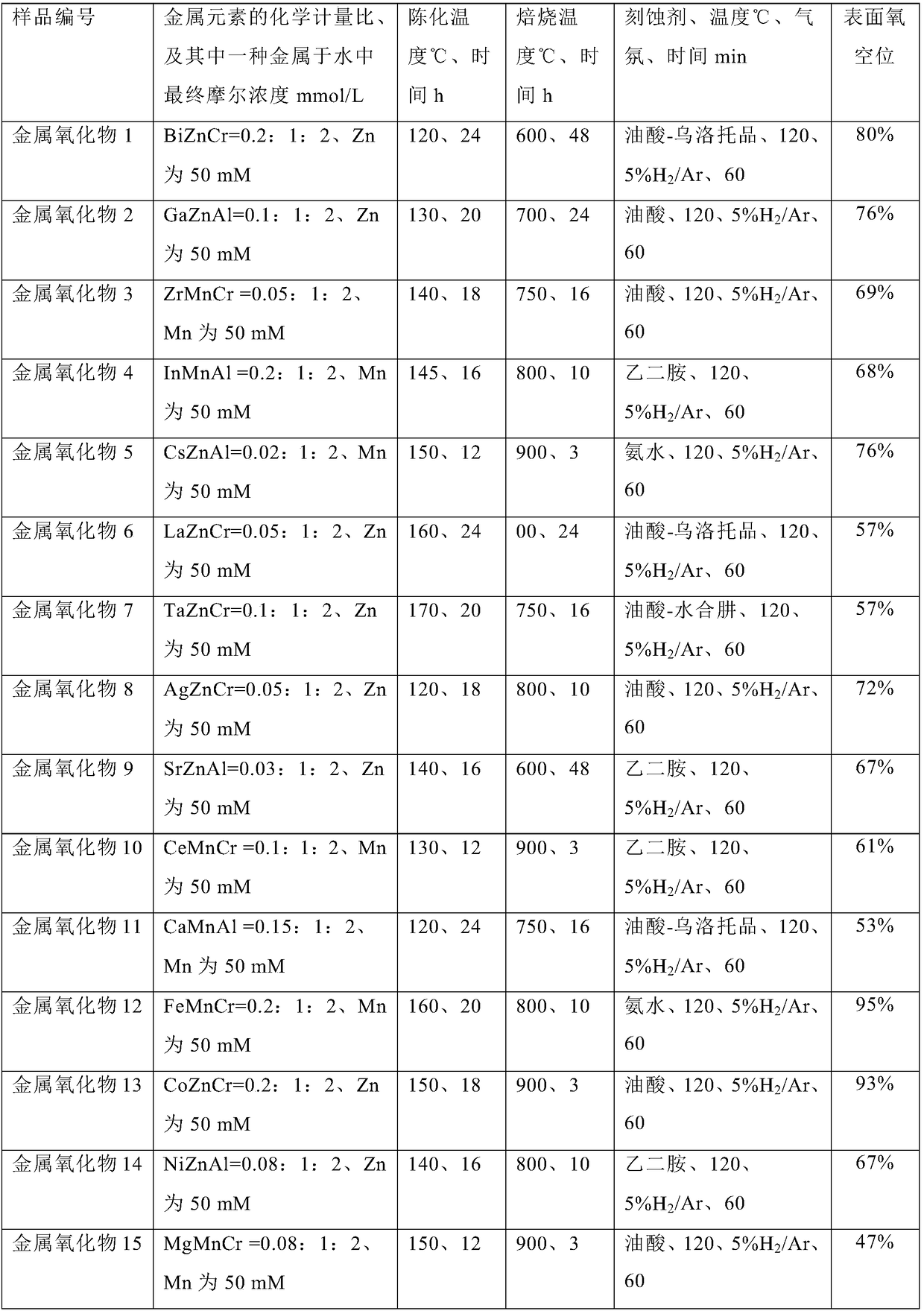

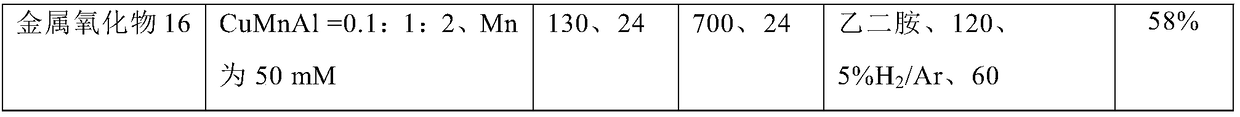

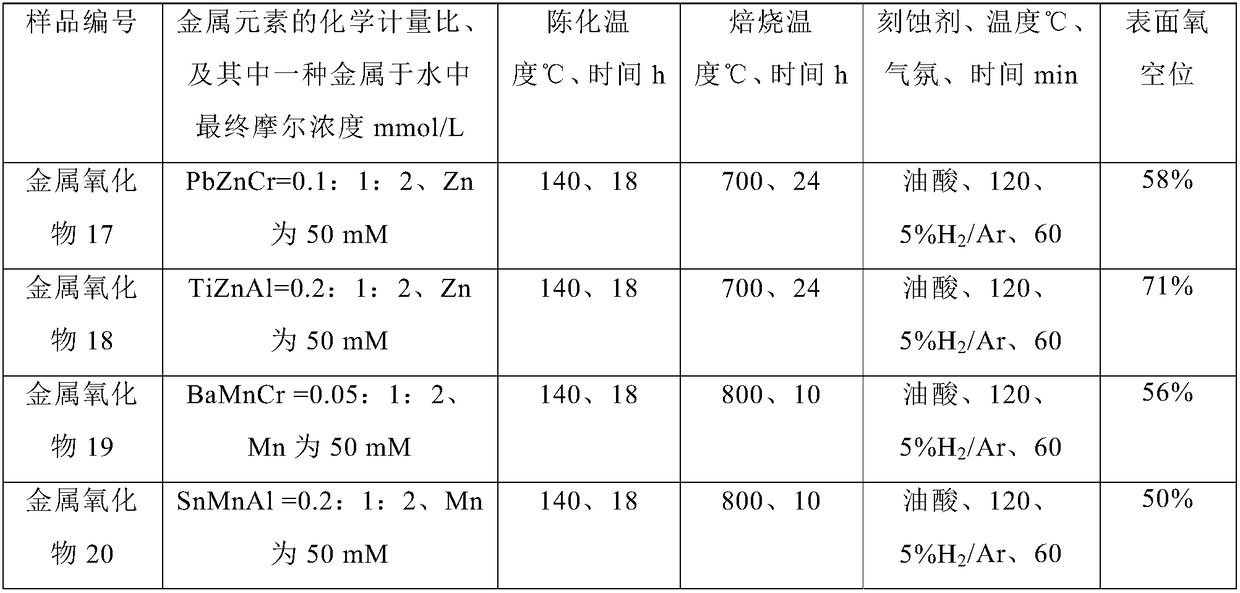

[0027] (1) The active metal oxide is M n+ MnCr 2 o 4+n / 2 , M n+ MnAl 2 o 4+n / 2 , M n+ ZnCr 2 o 4+n / 2 , M n+ ZnAl 2 o 4+n / 2 preparation of

[0028] (1) Use zinc nitrate, aluminum nitrate, chromium nitrate, and manganese nitrate as precursors, and then add 1-10% other metal nitrates and urea to mix with each other in water at room temperature; age the above mixed solution, and then take it out Washing, filtering and drying, the resulting solid is roasted under air atmosphere to obtain M n+ MnCr 2 o 4+n / 2 , M n+ MnAl 2 o 4+n / 2 , Mn+ ZnCr 2 o 4+n / 2 , M n+ ZnAl 2 o 4+n / 2 Metal oxide.

[0029] (2) Using etchant such as oleic acid, urotropine, ethylenediamine, ammonia water, hydrazine hydrate, etc., the above sample is ultrasonically mixed with the metal oxide at room temperature, and the metal oxide is soaked in the etchant solution, The etchant forms a complex with the metal oxide or undergoes a direct reductio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com