Graphene thin film electrode, preparation method thereof, graphene composite thin film interdigital electrode with conductive line formed on surface and capacitor

A technology of graphene film and film electrode, which is applied in the manufacture of hybrid capacitor electrodes, hybrid capacitor current collectors, and hybrid/electric double layer capacitors. Promotion and application, easy integration, and the effect of improving energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

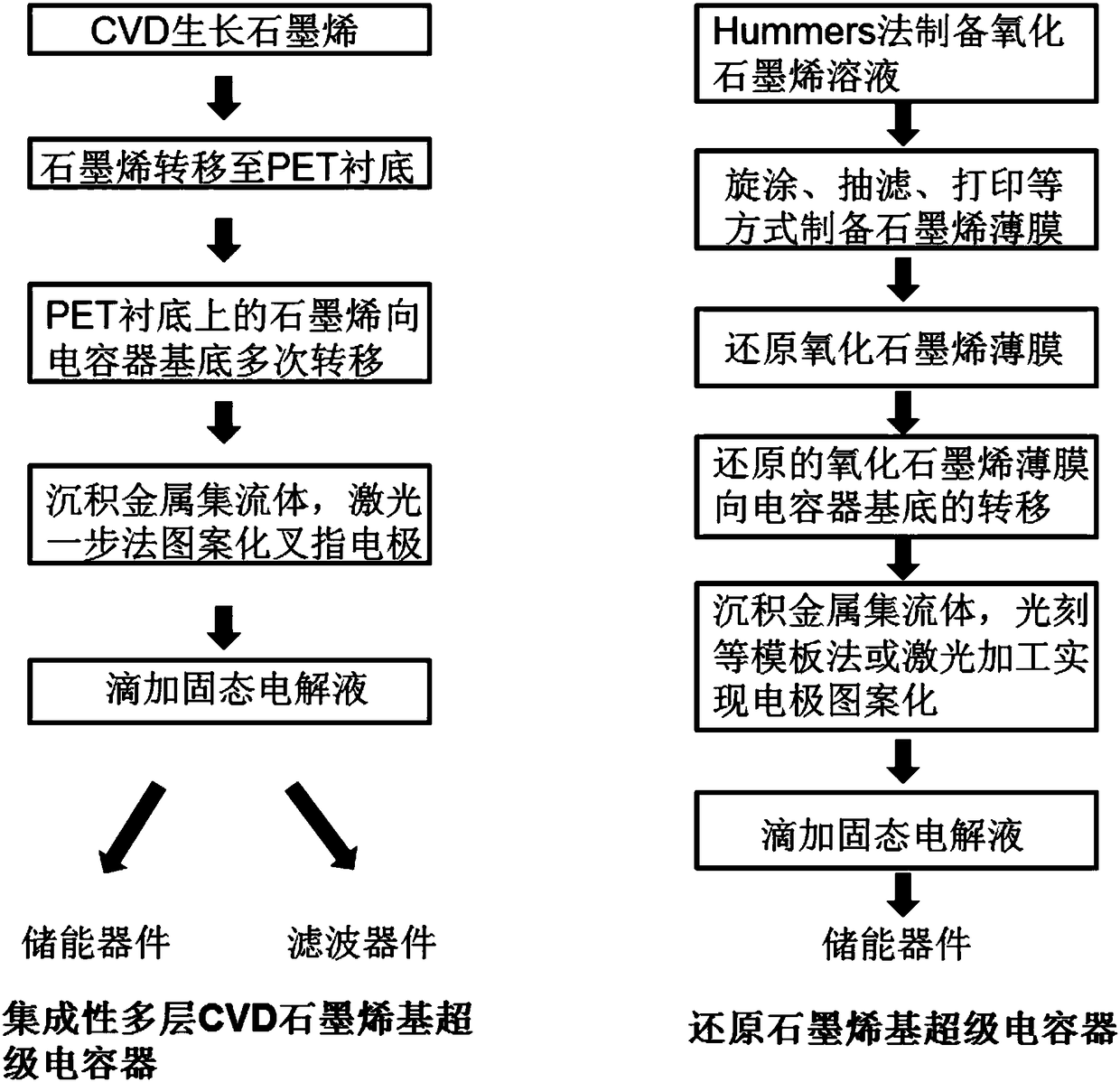

Method used

Image

Examples

preparation example Construction

[0092] The present invention also provides a kind of preparation method of graphene film electrode, comprises the following steps:

[0093] a) Composite a single-layer graphene sheet grown on a metal substrate on a flexible substrate, and remove the metal substrate by an etching solution to obtain an intermediate product;

[0094] b) transferring the single-layer graphene sheet on the intermediate product obtained in the above steps to the electrode substrate to obtain an electrode substrate composited with a graphene film;

[0095] Said transfer includes a single transfer or multiple transfers;

[0096] c) Depositing a metal film on the graphene film of the electrode substrate compounded with the graphene film obtained in the above steps to obtain a graphene film electrode.

[0097] The selection, combination and preferred range of materials in the preparation method of the graphene thin film electrode in the present invention preferably correspond to the selection, combinat...

Embodiment 1

[0128] a) High-quality graphene was grown on copper foil (thickness 20 μm, area the size of a standard A4 paper) by chemical vapor deposition, the growth temperature was 1000 °C, the growth time was 10 min, CH 4 Gas flow rate is 10sccm, hydrogen 10sccm;

[0129] b) The copper foil grown with graphene is tightly attached to the PET substrate (Cu / PET) by rolling, and the Cu / PET film is placed in 0.5M (NH 4 )S 2 o 8 In the etching solution, the etching time is 2 to 4 hours to completely etch Cu;

[0130] c) Lay the resulting flexible PET / graphene substrate to the supercapacitor PET substrate (125 μm), or to the PTFE film substrate, and after keeping it at 90°C for 20 minutes, slowly peel off the PET substrate to realize graphene Transfer to PET substrate / PTFE substrate;

[0131] d) Repeat step c) 3 times to obtain a 3-layer graphene film conductive film electrode, the size of which is the size of a standard A4 paper.

Embodiment 2

[0133] a) High-quality graphene was grown on copper foil (thickness 20 μm, area the size of a standard A4 paper) by chemical vapor deposition, the growth temperature was 1030 °C, and the growth time was 20 min; CH 4 The gas flow rate is 3 sccm, and the hydrogen gas is 10 sccm;

[0134] b) The graphene-grown copper foil is tightly attached to the PET substrate (Cu / PET) by rolling, and the Cu / PET film is placed in 0.5M FeCl 3 In the etching solution, the etching time is 1 to 2 hours to completely etch Cu;

[0135] c) cutting the resulting flexible PET / graphene substrate into a size of 25 cm 2 A small piece; and bonded to the supercapacitor PET substrate (50 μm), after maintaining at 100 ° C for 20 minutes, slowly peel off the PET substrate, so as to realize the transfer of graphene to the PET substrate;

[0136] d) Repeat step c) 6 times to obtain a 6-layer graphene film conductive film electrode with a size of 25cm 2 .

[0137] see figure 2 , figure 2 It is the physical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

| Layer spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com