Radial flow dividing and concentrating apparatus for water-erosion-monitored district

A hydraulic erosion and flow collecting device technology, which is applied in the direction of soil material testing, material inspection products, etc., can solve the problems of easy peeling off of the pool wall, inconsistent flow, and difficult cleaning, so as to achieve fast and easy mixing of samples and improve sampling accuracy , The effect of convenient sampling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

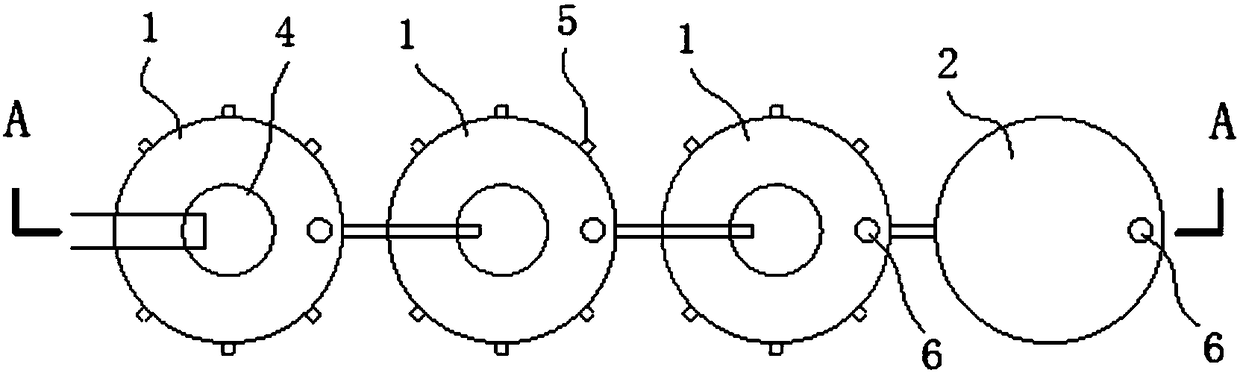

[0025] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the runoff diversion and collection device used in the hydraulic erosion monitoring community includes a collecting barrel 2 and more than one diverting barrel 1, and each diverging barrel 1 is connected in series in sequence. The splitter barrel 1 is connected to the collector barrel 2.

[0026] The shunt barrel 1 is a cylindrical barrel body 3, and the material of the barrel body 3 is a high-strength anti-corrosion alloy (such as galvanized iron sheet, etc.), and its inner diameter is 1m, which better avoids the dead angle problem inside the barrel body, and the sampling process is more convenient. A discharge port 6 is reserved at the bottom to make cleaning more convenient. The barrel body 3 is provided with a flexibly detachable flow grid 4, which can be circular, and a plural...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com