A kind of iron-based amorphous strip material and its preparation method and the preparation method of high-frequency high-permeability nanocrystalline alloy

A nanocrystalline alloy, iron-based amorphous technology, applied in the field of magnetic materials, can solve the problems of low industrial production efficiency, high production cost, complex process, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

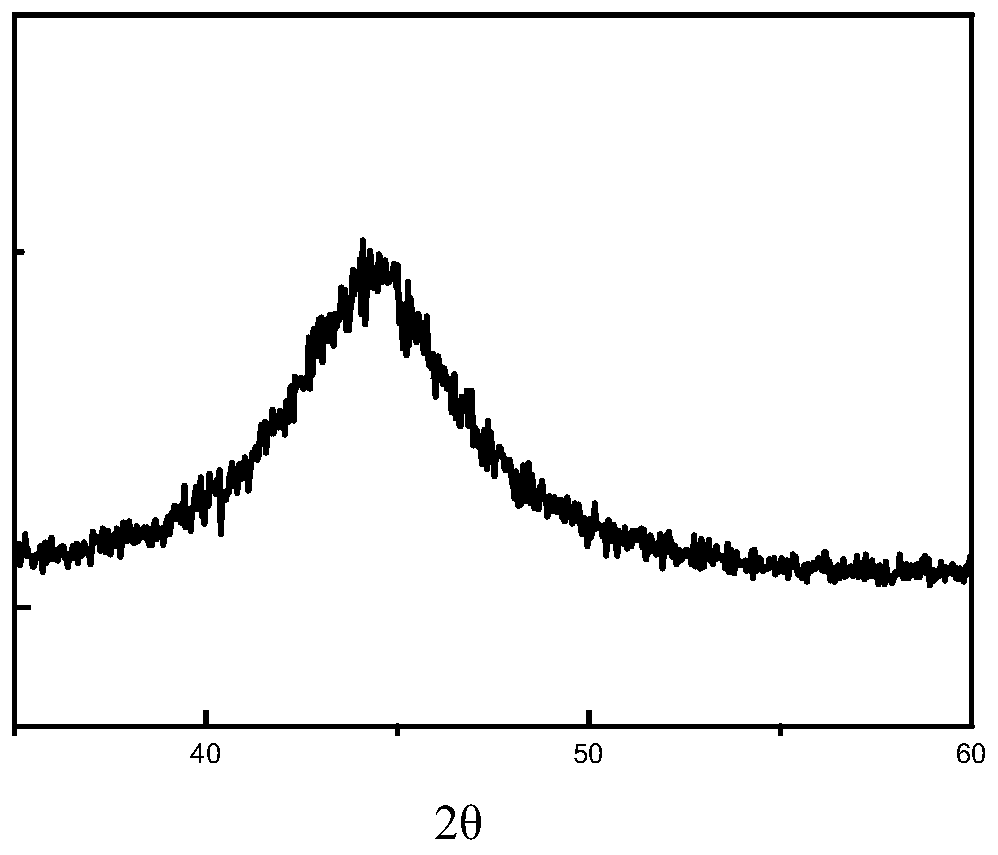

Image

Examples

preparation example Construction

[0037] The present invention provides a method for preparing the iron-based amorphous strip described in the above technical solution, comprising: subjecting the master alloy including the iron-based amorphous strip with a limited composition to strip-spinning treatment to obtain the iron-based amorphous strip.

[0038] In the present invention, the master alloy is preferably obtained by self-preparation. The present invention has no special requirements on the preparation process of the master alloy, and uses a medium frequency induction heating process well known to those skilled in the art for smelting. In the present invention, the preparation method of the master alloy preferably includes: melting and casting metal raw materials satisfying the defined composition ratio of the iron-based amorphous strip. The present invention has no special requirements on the type and amount of the metal raw material, as long as the composition of the iron-based amorphous strip can be sat...

Embodiment 1

[0059] Using an intermediate frequency furnace, the metal raw materials that meet the defined composition ratio of the iron-based amorphous strip: electrical pure iron (>99.9%), metal silicon (>99%), ferroboron (16-18% boron content) , ferroniobium (64-66% niobium content), ferro-vanadium (50-55% vanadium content), pure copper (>99.9%) and pure cobalt (>99.9%), smelted in a vacuum environment before casting, A master alloy comprising the defined components of the iron-based amorphous strip was obtained, wherein the molar fractions of each metal element were: 69.5 parts of iron, 16.5 parts of silicon, 8.5 parts of boron, 3.0 parts of niobium, 1.0 part of vanadium, and 1.3 parts of copper parts and 0.2 parts of cobalt, that is, the composition of the master alloy is Fe 69.5 Si 16.5 B 8.5 Nb 3.0 V 1. 0 Cu 1.3 co 0.2 .

[0060] After the master alloy is melted, strip stripping treatment is carried out by using a pressure single-roll strip stripping machine, and the tempera...

Embodiment 2

[0065] Using an intermediate frequency furnace, the metal raw materials that meet the defined composition ratio of the iron-based amorphous strip: electrical pure iron (>99.9%), metal silicon (>99%), ferroboron (16-18% boron content) , ferroniobium (containing 64-66% niobium), ferro-vanadium (containing 50-55% vanadium), pure copper (>99.9%) and pure cobalt (>99.9%), smelted in a vacuum environment before casting, A master alloy comprising the defined components of the iron-based amorphous strip was obtained, wherein the molar fractions of each metal element were: 70.5 parts of iron, 17 parts of silicon, 7.5 parts of boron, 2.5 parts of niobium, 0.5 parts of vanadium, and 1.3 parts of copper parts and 0.8 parts of cobalt, that is, the composition of the master alloy is Fe 70.5 Si 17 B 7.5 Nb 2.5 V 0.5 Cu 1. 2 co 0.8 .

[0066] After the master alloy is melted, strip stripping treatment is carried out by using a pressure single-roll strip stripping machine, and the temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com