Processing method of matcha handmade soap and obtained matcha handmade soap

A processing method and handmade soap technology, applied in chemical instruments and methods, alkali soap/ammonium soap composition, molded soap, etc., can solve problems such as the inability to meet consumers' health and environmental protection concepts, achieve elimination of computer radiation hazards, and improve efficiency and quality, the effect of speeding up the degree of completion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

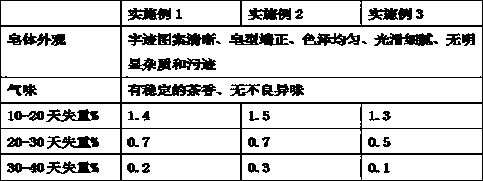

Embodiment 1

[0029] This embodiment provides a kind of processing method of matcha handmade soap and the matcha handmade soap obtained by the method, wherein the processing method comprises:

[0030] Ingredients: quantitatively weigh oil, sodium hydroxide, and water, wherein the molar ratio of oil to sodium hydroxide is 1:3, and the mass ratio of sodium hydroxide to water is 1:2.4;

[0031] Saponification: Dissolve sodium hydroxide in water, mix it with oil, add matcha which accounts for 2% of the total weight of raw materials and react, the reaction temperature is 70 degrees Celsius, the stirring rate is 15 rpm, and the reaction time is 4 hours; Wherein, the matcha is tea leaves picked within one day, steamed and microwaved, the temperature of steaming is 160 degrees Celsius, the humidity is 80%, the time is 8 minutes, and the time of microwave curing is 3 minutes; Squeeze the tea cake after the steam fixation and microwave fixation, separate the liquid phase therein, and use it as water ...

Embodiment 2

[0037] This embodiment provides a kind of processing method of matcha handmade soap and the matcha handmade soap obtained by the method, wherein the processing method comprises:

[0038] Ingredients: quantitatively weigh oil, potassium hydroxide, and water, wherein the molar ratio of oil to potassium hydroxide is 1: 3.5, and the mass ratio of potassium hydroxide to water is 1: 2.8;

[0039] Saponification: Dissolve potassium hydroxide in water, mix it with oil, add matcha which accounts for 5% of the total weight of the raw materials, and react. The reaction temperature is 80 degrees Celsius, the stirring rate is 8 revolutions per minute, and the reaction time is 6 hours. , the matcha is tea leaves picked within one day, steamed and microwaved, the steaming temperature is 180 degrees Celsius, the humidity is 83%, the time is 6 minutes, and the microwave cleaning time is 4 minutes; Extruding the tea cakes after the steam-fixing and microwave-fixing, separating the liquid phase ...

Embodiment 3

[0045] This embodiment provides a kind of processing method of matcha handmade soap and the matcha handmade soap obtained by the method, wherein the processing method comprises:

[0046] Ingredients: Quantitatively weigh oil, sodium hydroxide, potassium hydroxide, and water, wherein the molar ratio of oil to the total amount of sodium hydroxide and potassium hydroxide is 1:3-3.5, and the ratio of sodium hydroxide, potassium hydroxide to water The mass ratio is 1:2.6;

[0047] Saponification: Dissolve sodium hydroxide and potassium hydroxide in water, mix them with oil, add matcha which accounts for 3.5% of the total weight of raw materials and react, the reaction temperature is 75 degrees Celsius, the stirring speed is 11 revolutions per minute, and the reaction time is 5 hours; wherein, the matcha tea leaves were picked within one day, steamed and microwaved, the steaming temperature was 170 degrees Celsius, the humidity was 81%, and the time was 7 minutes, and the microwave ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com