Meta drawing oil

A drawing oil and metal technology, applied in the field of lubricating oil, can solve the problems of dispersion, small production scale, no unified quality standard for drawing oil, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The invention provides a metal drawing oil, which consists of the following components by weight:

[0032] Antioxidant anticorrosion agent: 2.5 parts;

[0033] Rust inhibitor: 3.5 parts;

[0034] Metal deactivator: 3.5 parts;

[0035] Antifoaming agent: 0.001 part;

[0036] Friction modifier: 1.4 parts;

[0037] Viscosity index improver: 0.5 parts;

[0038] Extreme pressure antiwear agent: 13.0 parts;

[0039] Oily agent: 0.5 parts;

[0040] Base oil: balance.

Embodiment 2

[0042] A metal drawing oil, consisting of the following components by weight:

[0043] Antioxidant anticorrosion agent: 3.0 parts;

[0044] Rust inhibitor: 6.5 parts;

[0045] Metal deactivator: 4.0 parts;

[0046] Antifoaming agent: 0.0015 parts;

[0047] Friction modifier: 2.1 parts;

[0048] Viscosity index improver: 1.0 parts;

[0049] Extreme pressure antiwear agent: 20.5 parts;

[0050] Oily agent: 1.0 parts;

[0051] Base oil: balance.

Embodiment 3

[0053] The invention provides a metal drawing oil, which consists of the following components by weight:

[0054] Antioxidant anticorrosion agent: 3.5 parts;

[0055] Rust inhibitor: 8.0 parts;

[0056] Metal deactivator: 4.5 parts;

[0057] Antifoaming agent: 0.002 parts;

[0058] Friction modifier: 2.6 parts;

[0059] Viscosity index improver: 1.5 parts;

[0060] Extreme pressure antiwear agent: 26.5 parts;

[0061] Oily agent: 1.5 parts;

[0062] Base oil: balance.

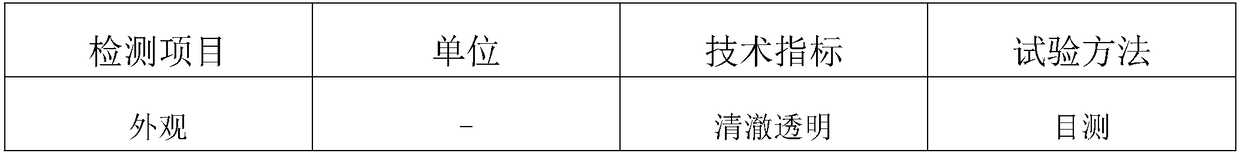

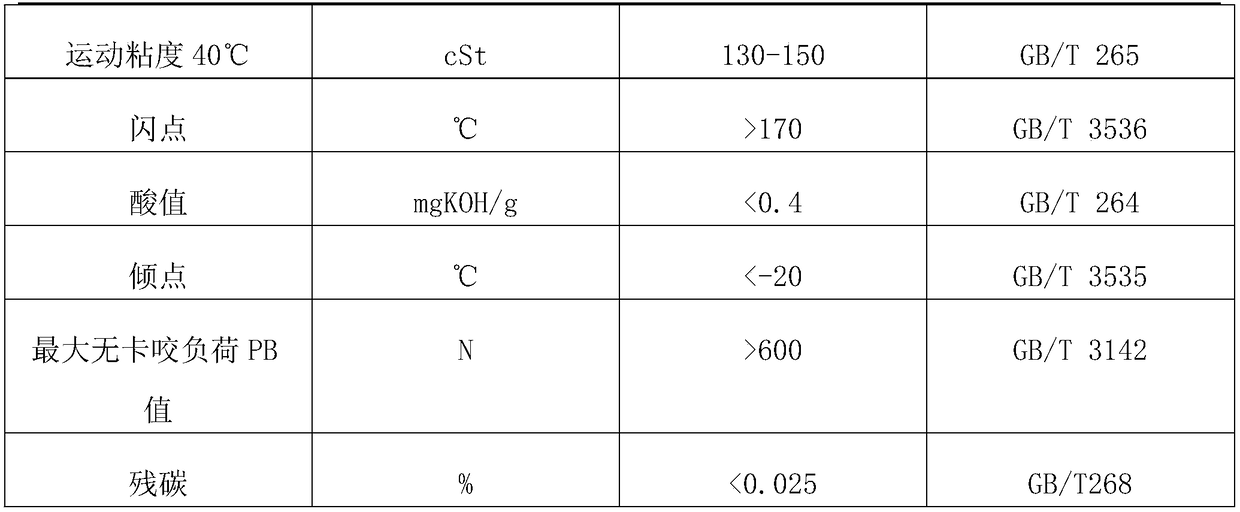

[0063] Drawing oil of the present invention draws result as follows after testing:

[0064]

[0065]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com