Environment-friendly plasticizer

An environmentally friendly plasticizer and adhesive technology, applied in the field of chemical additives, can solve the problems of plasticizer toxic substances, human injury, etc., and achieve the effects of enhanced insect repellent function, good adhesion performance and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] An environmentally friendly plasticizer, consisting of the following components by weight: 7 parts of 3-phthalic acid bis(4-chlorophenyl) ester, 28 parts of phthalic anhydride, 18 parts of 2-propylheptanol, plant 17 parts of sterols, 18 parts of organic solvents, 14 parts of oxides, 13 parts of soft polyvinyl chloride, 0.2 parts of roseic acid, 15 parts of acetalized polyvinyl alcohol, 40 parts of glycerin, 30 parts of vegetable oil, 0.8 parts of sodium alkoxide, fatty acid methyl 18 parts of ester, 17 parts of butyl acrylate, 13 parts of glycidyl methacrylate, 13 parts of epoxy fatty acid methyl ester, 7 parts of flying graphite, 7 parts of rosin, appropriate amount of palm oil and 11 parts of adhesive.

Embodiment 2

[0019] 7 parts of 3-di(4-chlorophenyl) phthalate, 22 parts of phthalic anhydride, 15 parts of 2-propylheptanol, 15 parts of phytosterol, 17 parts of organic solvent, 12 parts of oxide, soft 13 parts of polyvinyl chloride, 0.2 parts of rose acid, 12 parts of acetalized polyvinyl alcohol, 35 parts of glycerin, 25 parts of vegetable oil, 0.5 parts of sodium alkoxide, 10 parts of fatty acid methyl ester, 16 parts of butyl acrylate, glycidyl methacrylate 12 parts, 12 parts of epoxy fatty acid methyl ester, 6 parts of flying graphite, 6 parts of rosin, appropriate amount of palm oil and 10 parts of adhesive.

Embodiment 3

[0021] 8 parts of 3-di(4-chlorophenyl) phthalate, 30 parts of phthalic anhydride, 20 parts of 2-propylheptanol, 18 parts of phytosterol, 19 parts of organic solvent, 15 parts of oxide, soft 14 parts of polyvinyl chloride, 0.3 parts of rose acid, 18 parts of acetalized polyvinyl alcohol, 45 parts of glycerin, 35 parts of vegetable oil, 1 part of sodium alkoxide, 20 parts of fatty acid methyl ester, 18 parts of butyl acrylate, glycidyl methacrylate 14 parts of ester, 15 parts of epoxy fatty acid methyl ester, 8 parts of flying graphite, 8 parts of rosin, appropriate amount of palm oil and 12 parts of adhesive.

[0022] In the above three embodiments, the organic solvent includes perchlorethylene, ethylene glycol ether and triethanolamine, and the perchlorethylene, ethylene glycol ether and triethanolamine are composed in a mass ratio of 5:8:12.

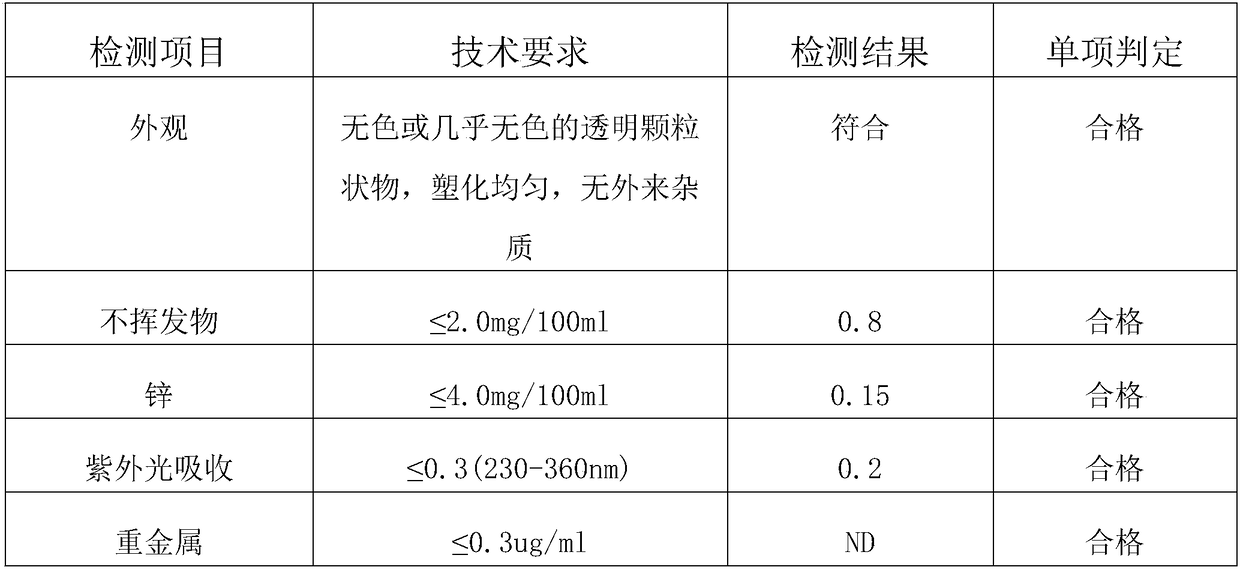

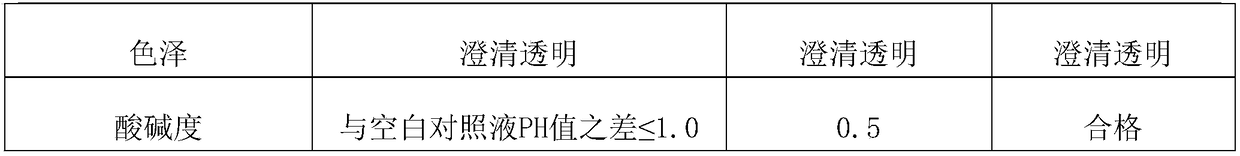

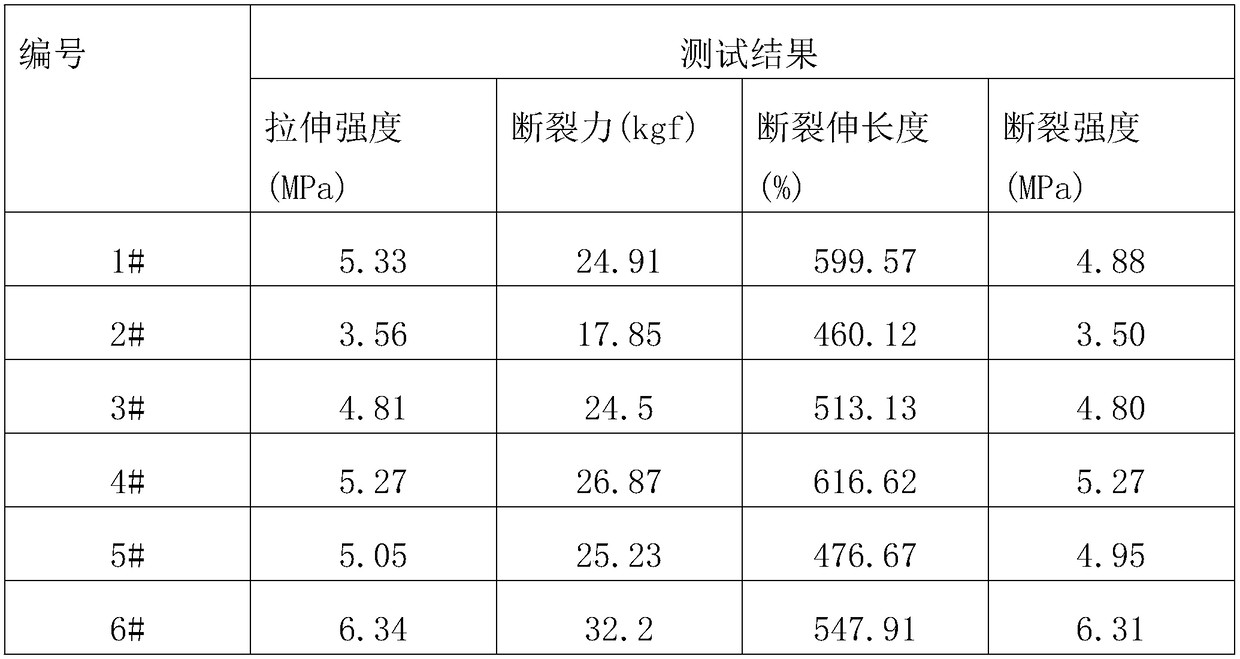

[0023] Use the performance parameter of plasticizer of the present invention (referring to table 1 and table 2):

[0024] Table 1:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com