Surface hydrophilic modified film and preparation method thereof

A hydrophilic and thin film technology, applied in the field of surface hydrophilic modified thin films and their preparation, can solve the problems of low pure water flux, reduced pore size and porosity, and inability to obtain permanent hydrophilic multilayer films.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

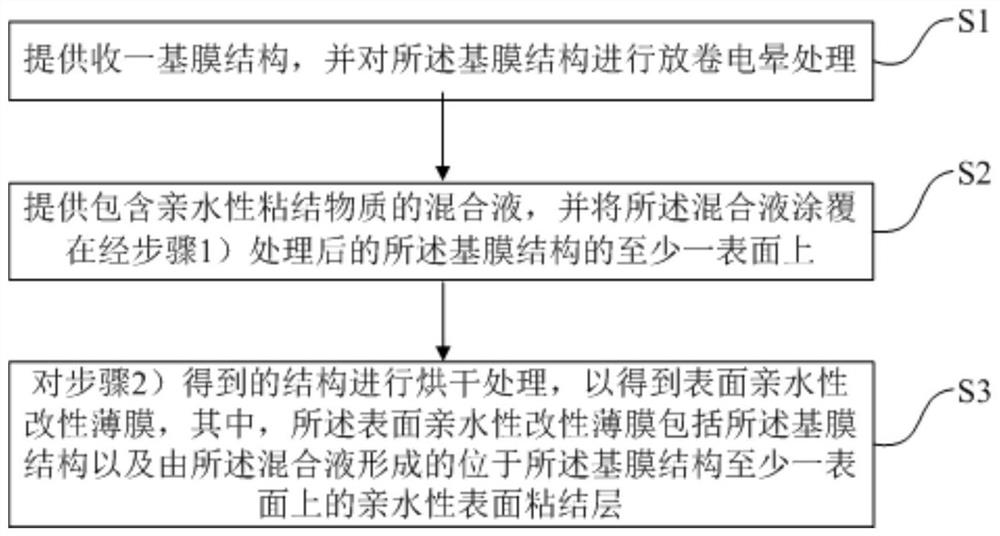

[0031] Such as figure 1 As shown, the present invention provides a kind of preparation method of surface hydrophilic modified film, and described preparation method comprises steps:

[0032] 1) Provide a base film structure, and carry out unwinding corona treatment on the base film structure;

[0033] 2) providing a mixed solution comprising a hydrophilic binding substance, and coating the mixed solution on at least one surface of the basement membrane structure treated in step 1); and

[0034] 3) drying the structure obtained in step 2) to obtain a surface hydrophilic modified film, wherein the surface hydrophilic modified film includes the base film structure and the structure formed by the mixed solution. A hydrophilic surface adhesive layer on at least one surface of the base membrane structure.

[0035] The preparation process of the surface hydrophilic modified film of the present invention will be described in detail below.

[0036] First, iffigure 1 As shown in S1, ...

Embodiment 1

[0073] Carry out unwinding corona treatment with the good polyethylene porous film (porosity 40%, aperture 40nm) of winding, processing voltage 5kV, processing line speed 50m / min, will contain the isopropyl alcohol of the polyvinyl alcohol of 20% weight part afterwards The alcohol solution was uniformly coated on the surface of the corona-treated film, then dried at 50°C for 1 hour, and the obtained film was wound up at a speed of 50 m / min to finally obtain a surface-hydrophilic modified film.

[0074] Porosity 40% Aperture 40nm Contact angle 53° pure water flux 1200L / m 2 ·h·0.1MPa

Embodiment 2

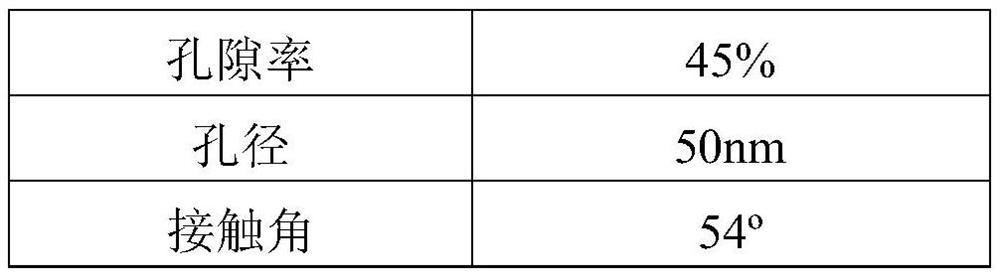

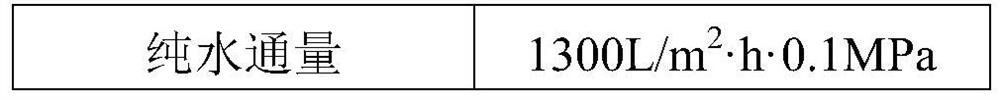

[0076] Carry out unwinding corona treatment with the good polypropylene porous membrane (porosity 45%, pore diameter 50nm) of winding, processing voltage 5kV, processing line speed 50m / min, will contain the isopropyl alcohol of the polyvinyl alcohol of 20% weight part afterwards The alcohol solution was uniformly coated on the surface of the corona-treated film, then dried at 50°C for 1 hour, and the obtained film was wound up at a speed of 50 m / min to finally obtain a surface-hydrophilic modified film.

[0077]

[0078]

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com