Method for synthesizing 1,8-cineole from terpilenol

A technology for terpineol and cineole, which is applied in the field of 1,8-cineole synthesis, can solve the problems of complex steps, difficult to control purity, low yield and the like, and achieves easy operation, short reaction time and high yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

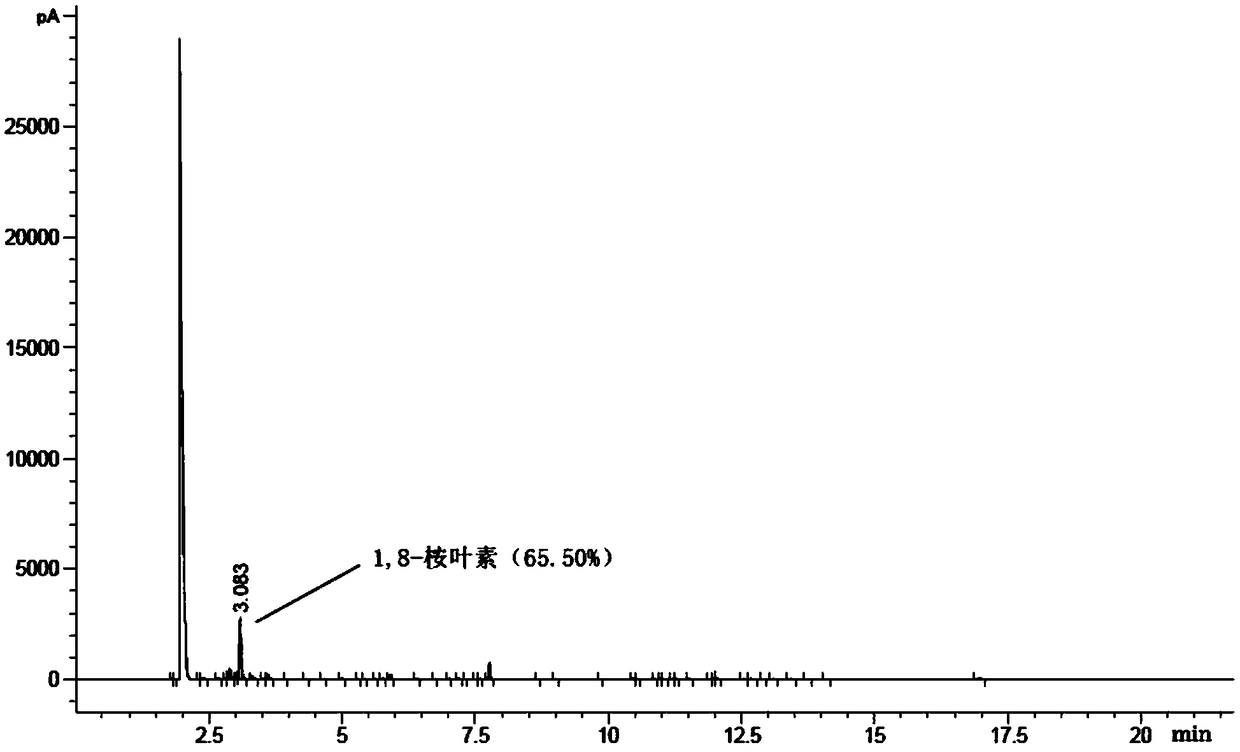

Embodiment 1

[0025] The method that terpineol synthesizes 1,8-cineole comprises the steps:

[0026] 1) The mass ratio of terpineol to dichloromethane is 1:13, and the mass ratio of terpineol to solid catalyst zinc trifluoromethanesulfonate is 1:10.4 into the reaction flask; under normal temperature and pressure, under nitrogen protection Stir with a stirrer for 4 hours at a speed of 80 rpm, and let it stand for 25 minutes after the reaction is completed to obtain the reaction solution I;

[0027] 2) Add dichloromethane to the reaction solution I, the mass ratio of terpineol to dichloromethane is 1:6, stir with a stirrer for 1 hour, and the rotation speed is 40 rpm to obtain the reaction solution II;

[0028] 3) Add saturated sodium bicarbonate solution to reaction solution II for extraction, the mass ratio of terpineol to saturated sodium bicarbonate solution is 1:19, let the layers stand for 10 minutes, and remove the lower layer solution to obtain reaction solution III;

[0029] 4) Wash...

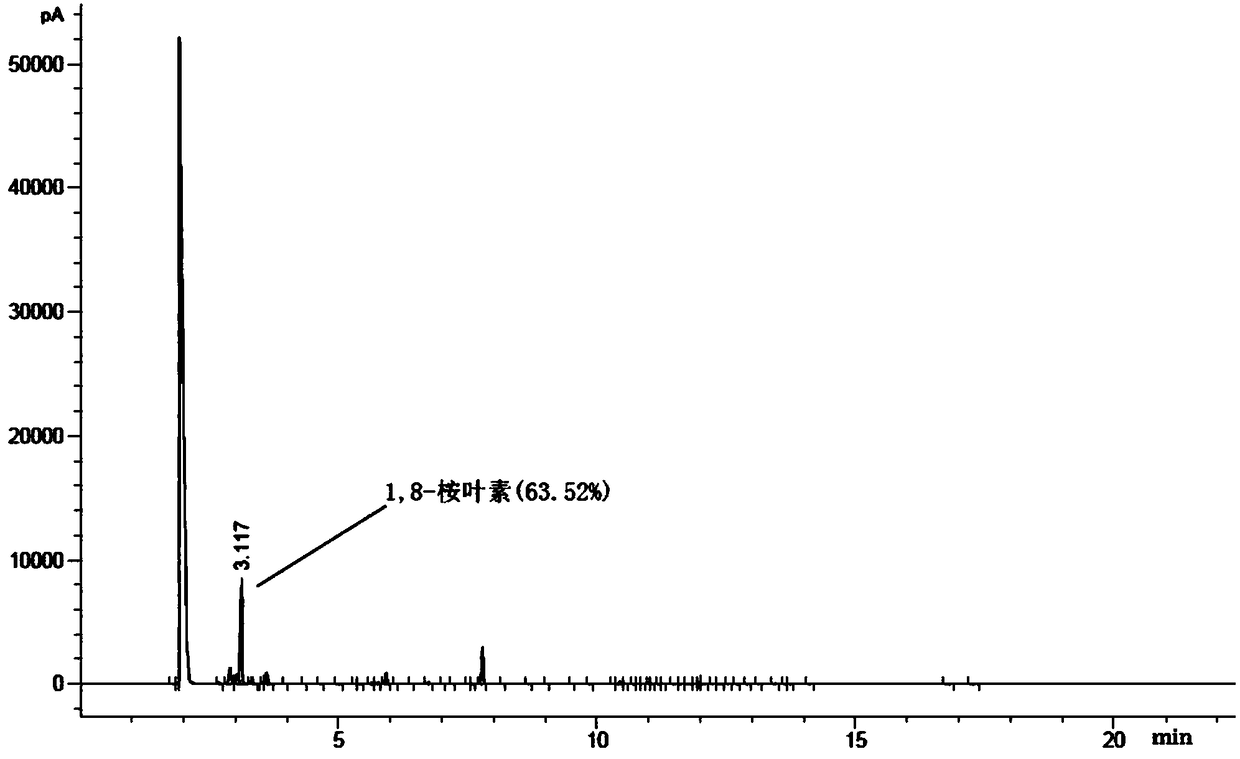

Embodiment 2

[0031] The method that terpineol synthesizes 1,8-cineole comprises the steps:

[0032] 1) The mass ratio of terpineol to dichloromethane is 1:8, and the mass ratio of terpineol to solid catalyst zinc trifluoromethanesulfonate is 1:7.4 and added to the reaction flask; under normal temperature and pressure, under nitrogen protection Stir with a stirrer for 4 hours at a speed of 85 rpm, and let it stand for 25 minutes after the reaction is complete to obtain a reaction solution I;

[0033] 2) Add dichloromethane to the reaction solution I, the mass ratio of terpineol to dichloromethane is 1:4.5, stir with a stirrer for 1 hour, and the rotation speed is 45 rpm to obtain the reaction solution II;

[0034] 3) Add saturated sodium bicarbonate solution to reaction solution II for extraction, the mass ratio of terpineol to saturated sodium bicarbonate solution is 1:13.5, let the layers stand for 10 minutes, and remove the lower layer solution to obtain reaction solution III;

[0035] ...

Embodiment 3

[0037] The method that terpineol synthesizes 1,8-cineole comprises the steps:

[0038] 1) The mass ratio of terpineol to dichloromethane is 1:3.5, and the mass ratio of terpineol to solid catalyst zinc trifluoromethanesulfonate is 1:4.3 into the reaction flask; under normal temperature and pressure, under nitrogen protection Stir with a stirrer for 4 hours at a speed of 90 rpm, and let stand for 25 minutes after the reaction is complete to obtain a reaction solution I;

[0039] 2) Add dichloromethane to the reaction solution I, the mass ratio of terpineol to dichloromethane is 1:2.8, stir with a stirrer for 1 hour, and the rotation speed is 50 rpm to obtain the reaction solution II;

[0040] 3) adding saturated sodium bicarbonate solution to the reaction solution II for extraction, the mass ratio of terpineol to saturated sodium bicarbonate solution was 1:8.2, standing for 10 minutes, and removing the lower layer solution to obtain reaction solution III;

[0041] 4) Wash the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com