Spent bleaching clay-based organic fertilizer, and preparation method and application thereof

A technology of waste white soil base and organic fertilizer, which is applied in the preparation, application and application of organic fertilizers, can solve the problems of life and property hazards, endanger the groundwater quality, increase the economic burden, etc., so as to improve soil conditions and increase production. Efficiency and economic benefits, the effect of protecting the ecological environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

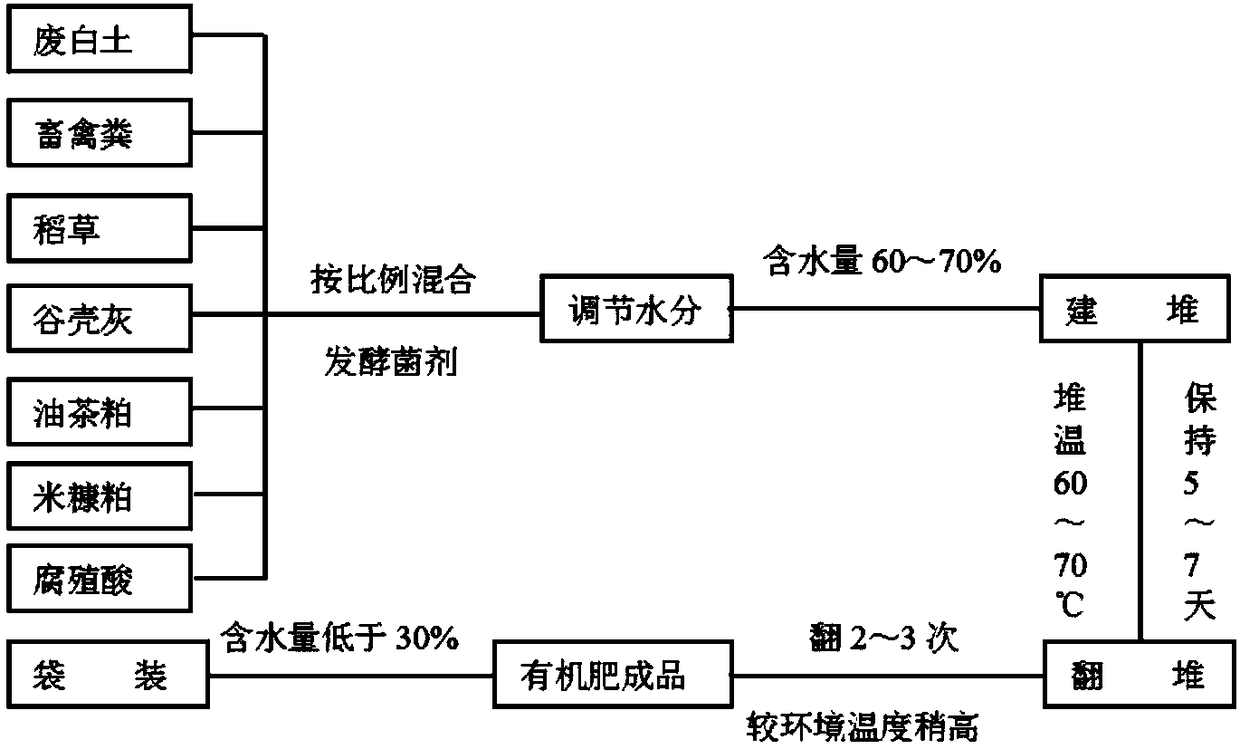

Method used

Image

Examples

Embodiment 1

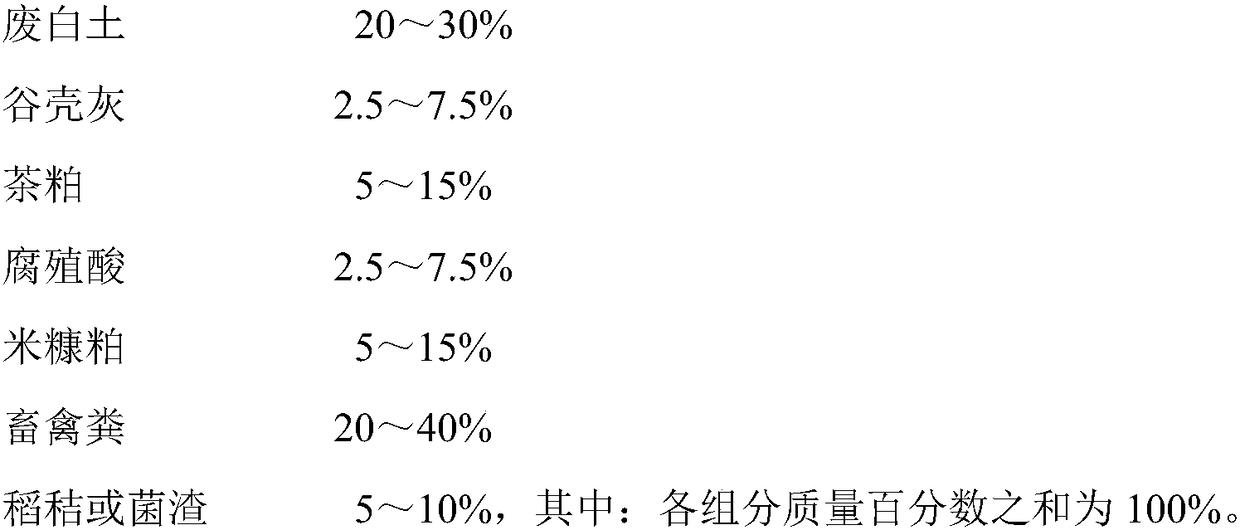

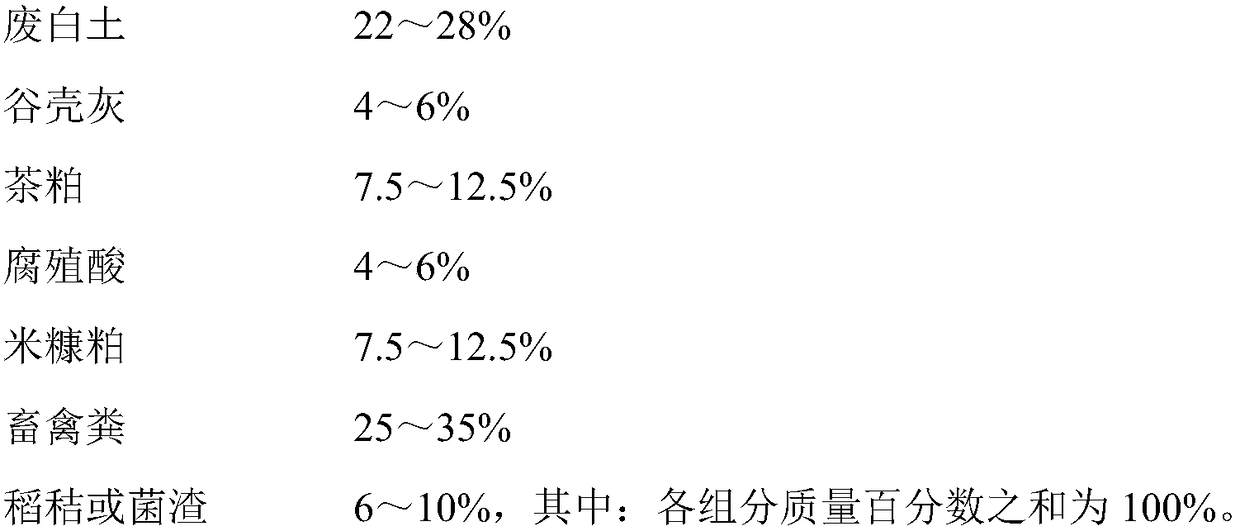

[0051] A waste clay-based organic fertilizer of this embodiment is calculated on a dry basis. The organic fertilizer is prepared from the following components in mass percent: 30 kg of waste clay, 5 kg of chaff ash, 10 kg of tea dregs, 5kg of phytic acid, 10kg of rice bran meal, 30kg of livestock and poultry manure, and 10kg of rice straw, of which: the total mass of each component is 100kg.

[0052] The above-mentioned waste clay-based organic fertilizer of the present embodiment is prepared by the following method, including the following steps:

[0053] (1) Selection of raw materials for composting

[0054] Waste white clay: high organic matter content, strong adsorption, good deodorization, can prevent and reduce the volatilization of ammonia, comprehensive nutrients, clean and hygienic, low raw material cost.

[0055] Chaff ash: Alkaline, high in silicon and potassium, strong in adsorption, good for nutrient retention;

[0056] Tea dregs and rice bran dregs: high in eff...

Embodiment 2

[0068] A kind of waste clay-based organic fertilizer of the present embodiment is calculated on a dry basis, and the organic fertilizer is prepared from the raw materials of the following components in mass percent: 20 kg of waste clay, 7.5 kg of chaff ash, 15 kg of tea dregs, Humic acid 7.5kg, rice bran meal 15kg, livestock and poultry manure 30kg, fungus residue 5kg, of which: the total mass of each component is 100kg.

[0069] This example adopts the same preparation method as Example 1 to prepare the organic fertilizer, the only difference being that the quality of the raw material components is different.

Embodiment 3

[0071] A kind of waste clay-based organic fertilizer of the present embodiment is calculated on a dry basis, and the organic fertilizer is prepared from the following components in mass percent: 30 kg of waste clay, 2.5 kg of chaff ash, 5 kg of tea dregs, Humic acid 2.5kg, rice bran meal 10kg, livestock manure 40kg, rice straw 10kg, of which: the total mass of each component is 100kg.

[0072] This example adopts the same preparation method as Example 1 to prepare the organic fertilizer, the only difference being that the quality of the raw material components is different.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com