Separation and recovery device and method of micro-nano composite powder and its application

A micro-nano composite, separation and recovery technology, applied in solid separation, chemical instruments and methods, wet separation, etc., can solve the problems affecting the fluidity, bulk density, and high energy consumption of spherical powders, and achieve mass production. , Improve the fluid linear velocity, the effect of high ultrasonic utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

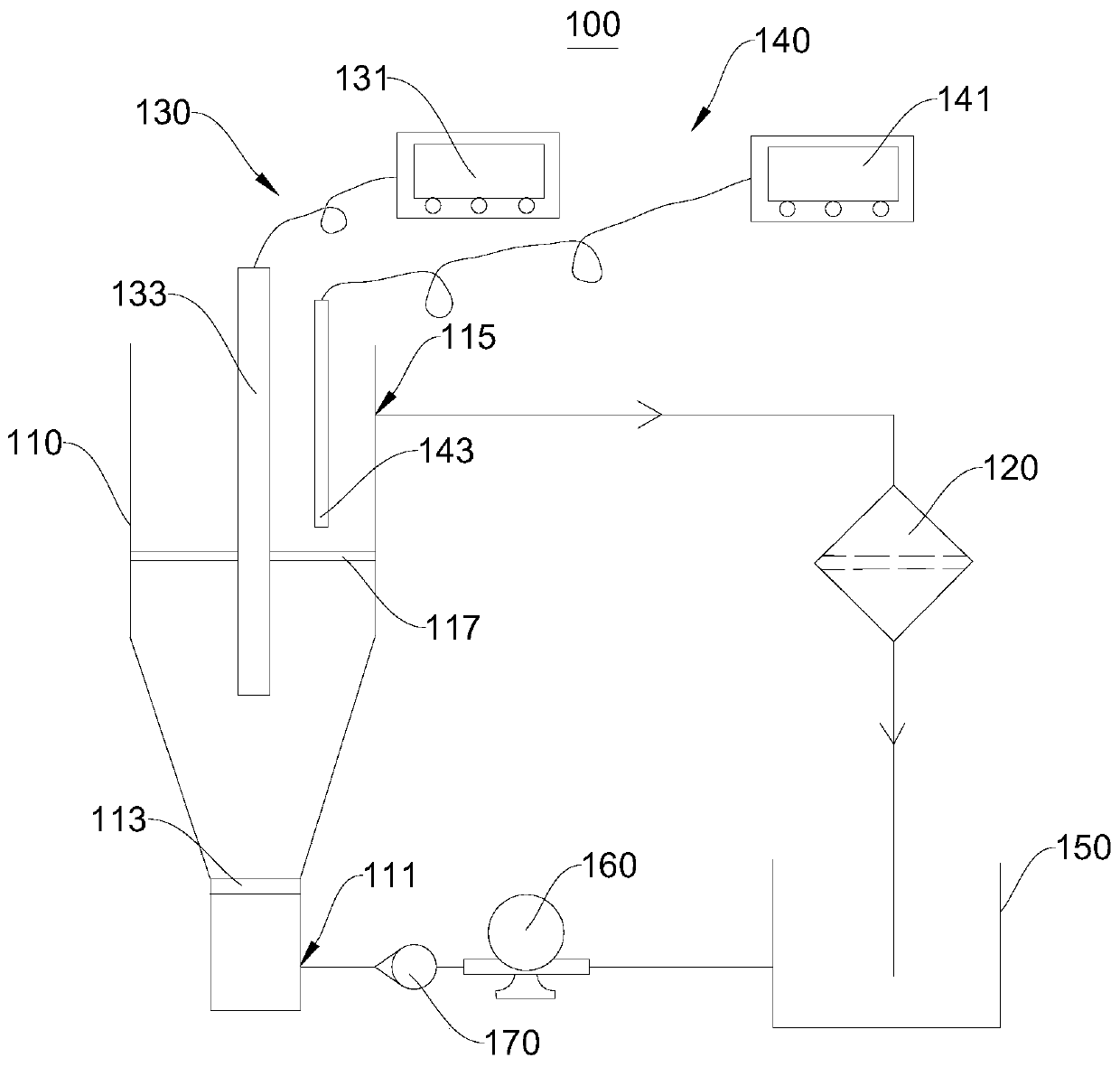

[0059] This embodiment provides a method for separating and recovering micro-nano composite powder, which uses the separation and recovery device for micro-nano composite powder provided by the present invention for separation and recovery. mainly includes:

[0060] Raw material: spherical tungsten powder produced by plasma spheroidization technology, average particle size (D 50 ) Is 26μm.

[0061] Parameter setting: the inclination angle of the side wall of the fluidized bed is 10 degrees, the opening rate of the distribution plate is 1%, and the pore size of the filter screen is 1000 mesh.

[0062] Put 20kg spherical tungsten powder in the fluidized bed, turn on the water pump, make the water in the liquid storage device enter from the inlet of the fluidized bed, adjust the flow regulator so that the water flow rate is 2L / min, make the spherical tungsten powder in Fluidized state.

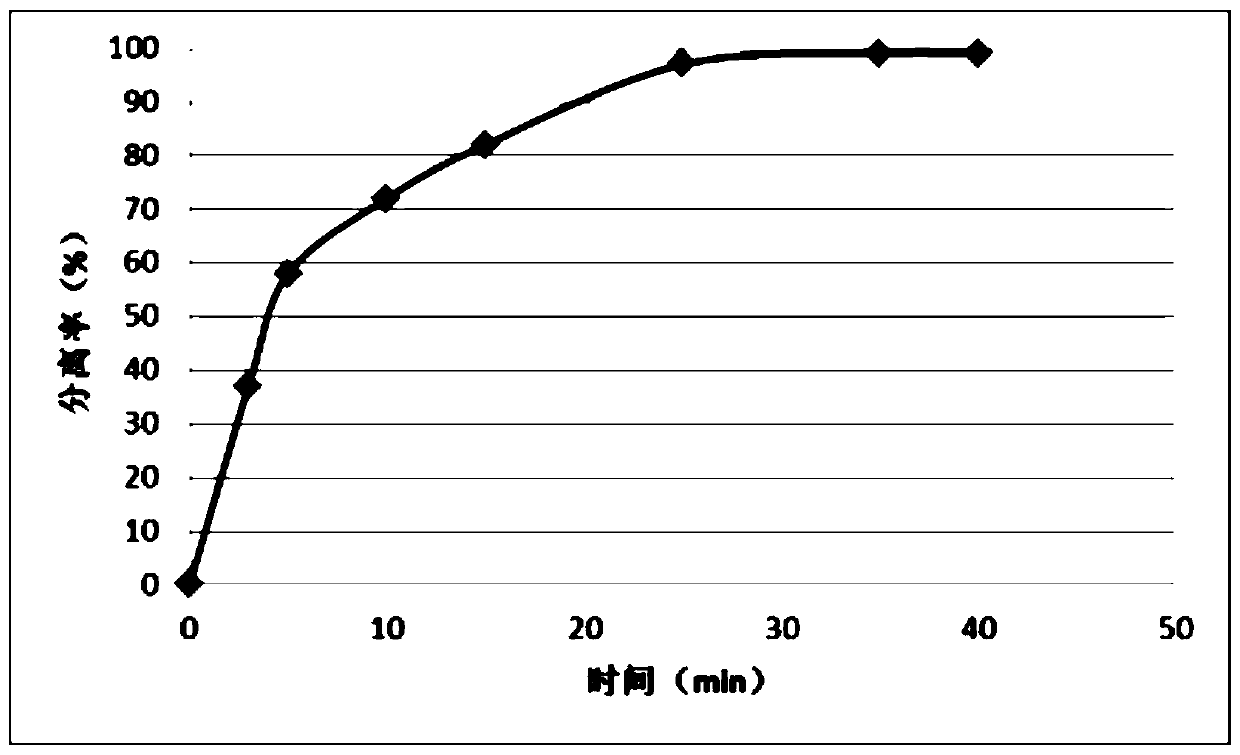

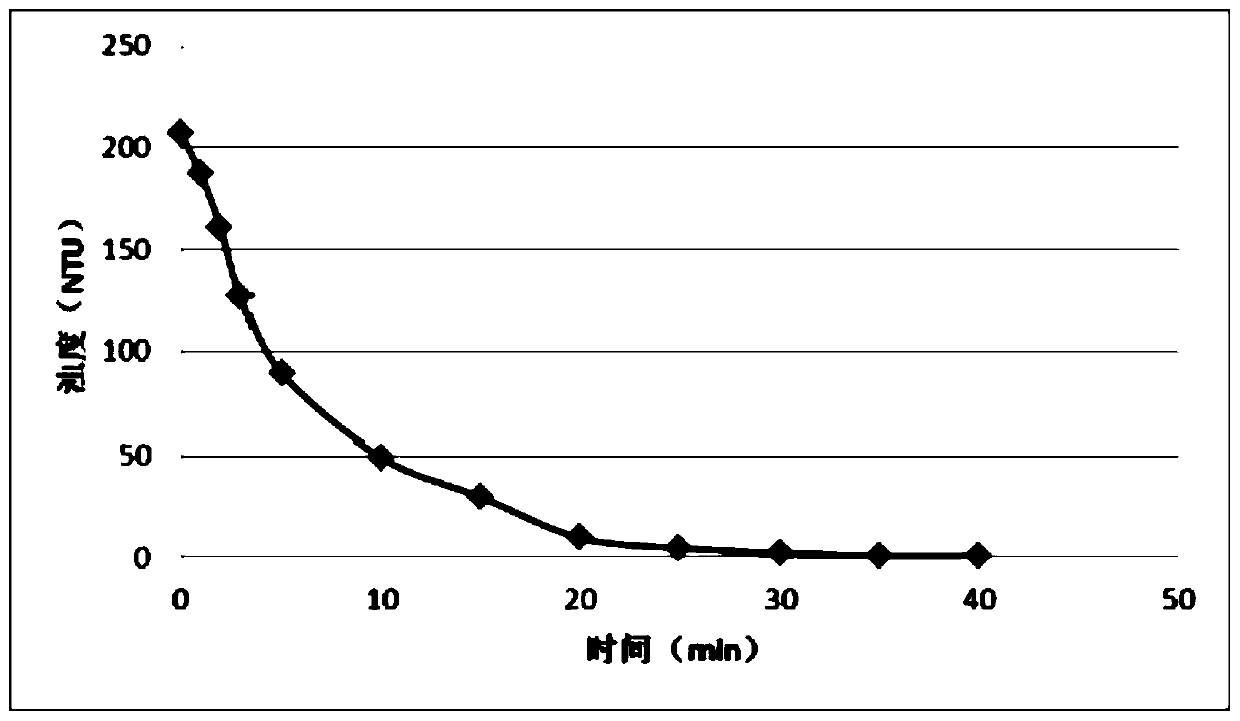

[0063] Place the ultrasonic vibrating rod and the water detection probe in the water in the fluidize...

Embodiment 2

[0067] This embodiment provides a method for separating and recovering micro-nano composite powder, which uses the separation and recovery device for micro-nano composite powder provided by the present invention for separation and recovery. mainly includes:

[0068] Raw material: spherical chromium powder produced by plasma spheroidization technology, average particle size (D 50 ) Is 16μm.

[0069] Parameter setting: the inclination angle of the side wall of the fluidized bed is 5 degrees, the opening rate of the distribution plate is 1.5%, and the pore size of the filter screen is 1500 mesh.

[0070] Put 1kg of spherical chromium powder in the fluidized bed, turn on the water pump, make the water in the liquid storage device enter from the inlet of the fluidized bed, adjust the flow regulator to make the water flow rate 0.5L / min, make the spherical chromium powder In a fluidized state.

[0071] Place the ultrasonic vibrating rod and the water detection probe in the water in the flui...

Embodiment 3

[0075] This embodiment provides a method for separating and recovering micro-nano composite powder, which uses the separation and recovery device for micro-nano composite powder provided by the present invention for separation and recovery. mainly includes:

[0076] Raw material: spherical Ti alloy powder produced by plasma spheroidization technology, average particle size (D 50 ) Is 30μm.

[0077] Parameter setting: the inclination angle of the side wall of the fluidized bed is 30 degrees, the opening rate of the distribution plate is 0.1%, and the pore size of the filter screen is 500 mesh.

[0078] Put 20kg spherical Ti alloy powder in the fluidized bed, turn on the water pump, make the water in the liquid storage device enter from the inlet of the fluidized bed, adjust the flow regulator so that the water flow rate is 1.5L / min, so that the spherical Ti The alloy powder is in a fluidized state.

[0079] Place the ultrasonic vibrating rod and the water detection probe in the water ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com