Difunctional cobalt diselenide material as well as preparation method and application thereof

A technology of cobalt diselenide and selenization, which is applied in the direction of binary selenium/tellurium compounds, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of unsatisfactory catalytic activity, stability, and electrocatalytic properties, and achieve the goal of preparing The effect of simple method and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The present invention provides a method for preparing cobalt diselenide, which includes the following steps:

[0034] (1) Place a mixed aqueous solution of soluble cobalt salt, soluble ammonium salt and carbon-containing precipitant together with a conductive substrate in a hydrothermal reaction vessel for hydrothermal reaction to obtain a cobalt precursor; wherein the mixed aqueous solution is soluble The molar ratio of cobalt salt, soluble ammonium salt and carbon-containing precipitant may be 1: (1-20): (10-50), and the concentration of the soluble ammonium salt in the mixed aqueous solution may be 0.01-0.3 mol / L;

[0035] The conductive substrate can be conductive glass or conductive metal substrate, such as foamed nickel, foamed copper, etc., preferably foamed nickel; foamed nickel can be of various sizes. The carbon-containing precipitant is preferably urea. Under the hydrothermal reaction temperature, urea reacts with other raw materials to combine metal atoms after...

Embodiment 1

[0041] figure 1 The preparation process of the dual-functional catalyst cobalt diselenide provided in this example is shown, including the following steps:

[0042] (1) Precursor preparation: 2.5mmol of cobalt nitrate, 10mmol of ammonium fluoride, 25mmol of urea raw materials were dissolved in 40mL of deionized water and reacted hydrothermally at 120°C for 16 hours. The precursor is obtained by washing and drying.

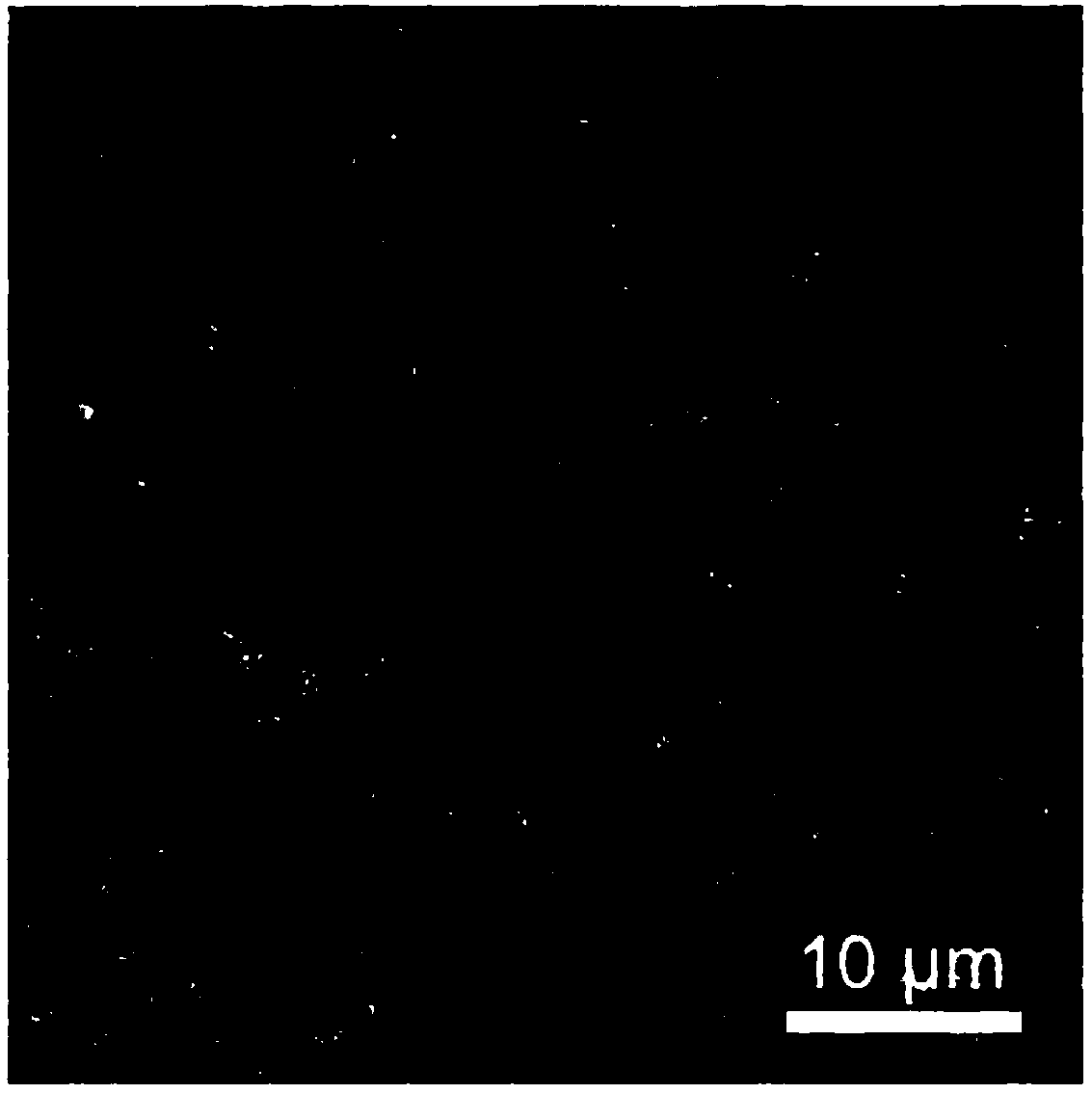

[0043] (2) Stable cobalt diselenide nanotubes: Mix selenium powder and sodium hydroxide at a molar ratio of 3.75 millimoles to 7.5 millimoles with 0.14 milliliters of hydrazine hydrate (85% by mass) and 50 milliliters of dimethylamide. Put the cobalt basic carbonate precursor into a two-step hydrothermal selenization reaction, react at 180°C for 1 hour, and obtain a cobalt diselenide catalyst after the reaction is dried. figure 2 The scanning electron microscope image of the stable cobalt diselenide catalyst provided by the example of the present invention is shown. i...

Embodiment 2

[0046] (1) Precursor preparation: 2.5mmol of cobalt nitrate, 10mmol of ammonium fluoride, 25mmol of urea raw materials were dissolved in 40mL of deionized water and reacted hydrothermally at 120°C for 16 hours. The precursor is obtained by washing and drying.

[0047] (2) Stable cobalt diselenide nanotubes: Mix selenium powder and sodium hydroxide at a molar ratio of 3.75 millimoles to 7.5 millimoles with 1 ml of hydrazine hydrate (85% by mass) and 50 ml of dimethylamide. Put the cobalt basic carbonate precursor into a two-step hydrothermal selenization reaction, react at 180°C for 1 hour, and obtain a cobalt diselenide catalyst after the reaction is dried.

[0048] (3) Preparation of electrode: The cobalt diselenide catalyst was finally dried at 60° C. for 6 hours, and small pieces of 1 square centimeter were cut out to obtain electrodes. The electrochemical performance of the catalyst was carried out in a three-electrode test cell. Ag / AgCl was used as the reference electrode, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com