A kind of epigallocatechin gallate nanowire preparation and its preparation method and application

A technology for epigallocatechin and gallate, which is applied to epigallocatechin gallate nanowire preparations and the fields of preparation and application thereof, can solve problems such as failure to achieve bacteriostatic or bactericidal effects, and achieve obvious effects , high repeatability, high safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

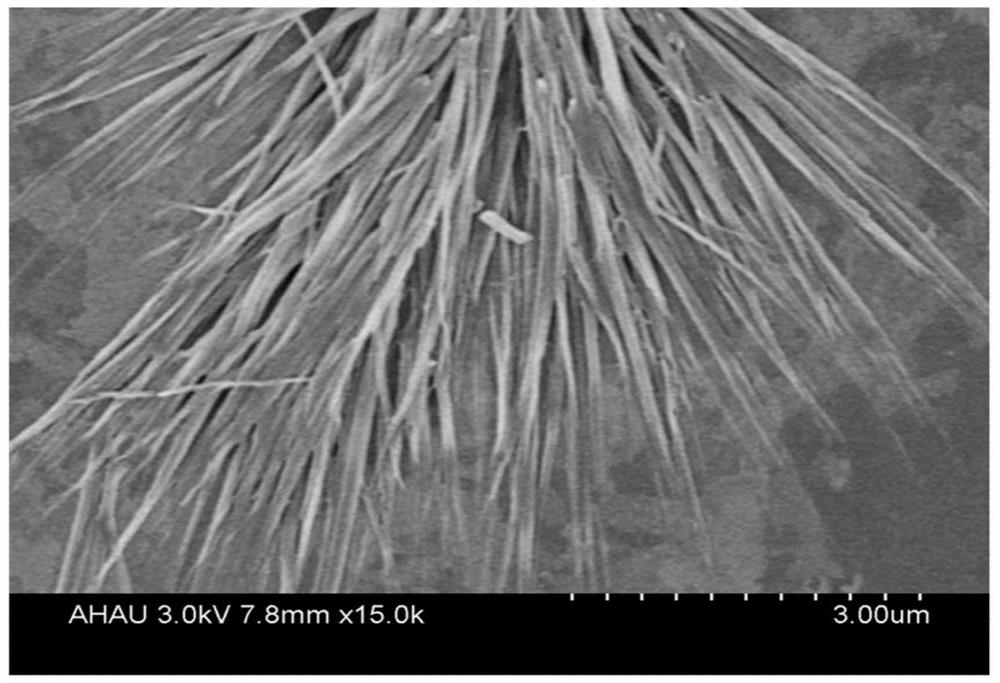

[0043] Preparation of Epigallocatechin Gallate Nanowire Preparation

[0044] The preparation method comprises the following steps:

[0045] (1) Raw material configuration

[0046] The configuration of organic phase raw materials: add 0.04 g of EGCG to 100 ml of anhydrous acetone, ultrasonically for 5 minutes, fully dissolve to obtain solution 1, and set aside; mix 0.2 ml of n-butyl α-cyanoacrylate and 4.0 ml of ethyl acetate thoroughly Immediately after adding solution 1, mix well to obtain the organic phase raw material, set aside;

[0047]The configuration of the water phase raw material: mix 0.8 g of sodium lauryl sulfate, 1.0 g of dextran-70 and 100 ml of ultrapure water, then adjust the pH value to 3.0 with 1mol / L hydrochloric acid to obtain the water phase raw material, and set aside;

[0048] (2) Polymerization reaction

[0049] After the organic phase raw material was magnetically stirred at room temperature for 20 minutes, it was slowly added dropwise to the aqueou...

Embodiment 2

[0056] Preparation of Epigallocatechin Gallate Nanowire Preparation

[0057] The preparation method comprises the following steps:

[0058] (1) Raw material configuration

[0059] The configuration of organic phase raw materials: add 0.06 g of EGCG to 100 ml of anhydrous acetone, ultrasonically for 5 minutes, fully dissolve to obtain solution 1, set aside; fully mix 0.3 ml of n-butyl α-cyanoacrylate and 6.0 ml of ethyl acetate Immediately after adding solution 1, mix well to obtain the organic phase raw material, set aside;

[0060] The configuration of the water phase raw material: mix 0.6 g of sodium lauryl sulfate, 0.8 g of dextran-70 and 100 ml of ultrapure water, then adjust the pH value to 2.5 with 1 mol / L hydrochloric acid to obtain the water phase raw material, and set aside;

[0061] (2) Polymerization reaction

[0062] After the organic phase raw material was magnetically stirred at room temperature for 23 minutes, it was slowly added dropwise to the aqueous phase...

Embodiment 3

[0067] Preparation of Epigallocatechin Gallate Nanowire Preparation

[0068] The preparation method comprises the following steps:

[0069] (1) Raw material configuration

[0070] The configuration of organic phase raw materials: add 0.08 grams of EGCG to 100 milliliters of anhydrous acetone, sonicate for 5 minutes, fully dissolve to obtain solution 1, and set aside; fully mix 0.4 milliliters of n-butyl α-cyanoacrylate and 8.0 milliliters of ethyl acetate Immediately after adding solution 1, mix well to obtain the organic phase raw material, set aside;

[0071] The configuration of the water phase raw material: mix 1.0 g of sodium lauryl sulfate, 1.2 g of dextran-70 and 100 ml of ultrapure water, then adjust the pH value to 2.0 with 1 mol / L hydrochloric acid to obtain the water phase raw material, and set aside;

[0072] (2) Polymerization reaction

[0073] After the organic phase raw material was magnetically stirred at room temperature for 27 minutes, it was slowly added ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorbance | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com