Battery tail piece pasting device

A tail piece and battery technology, applied in the field of battery tail piece sticking equipment, can solve the problems of unaligned tail piece sticking, low battery production efficiency, rework, etc., and achieve the effect of tight sticking, high alignment efficiency, and speeding up production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below by means of specific embodiments:

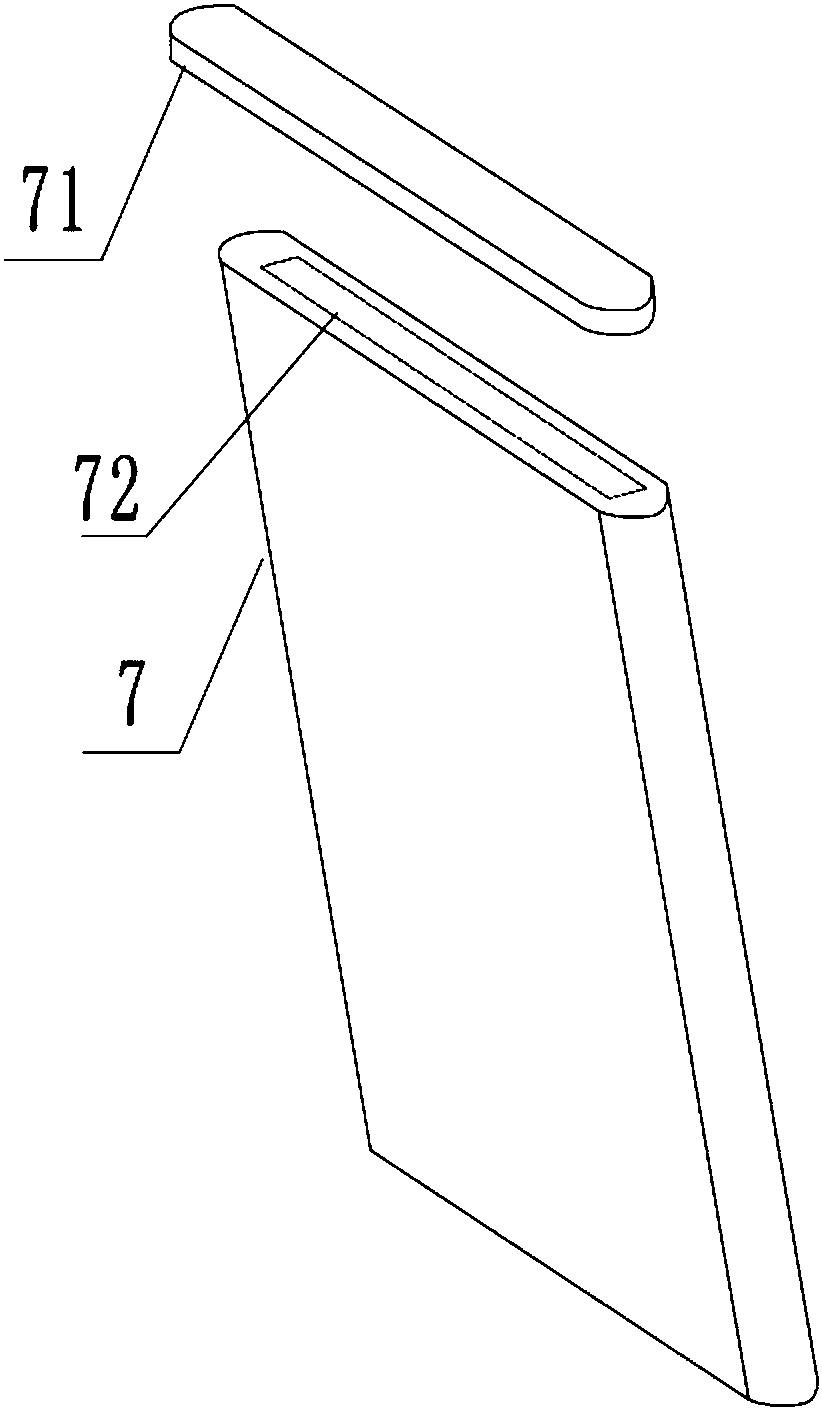

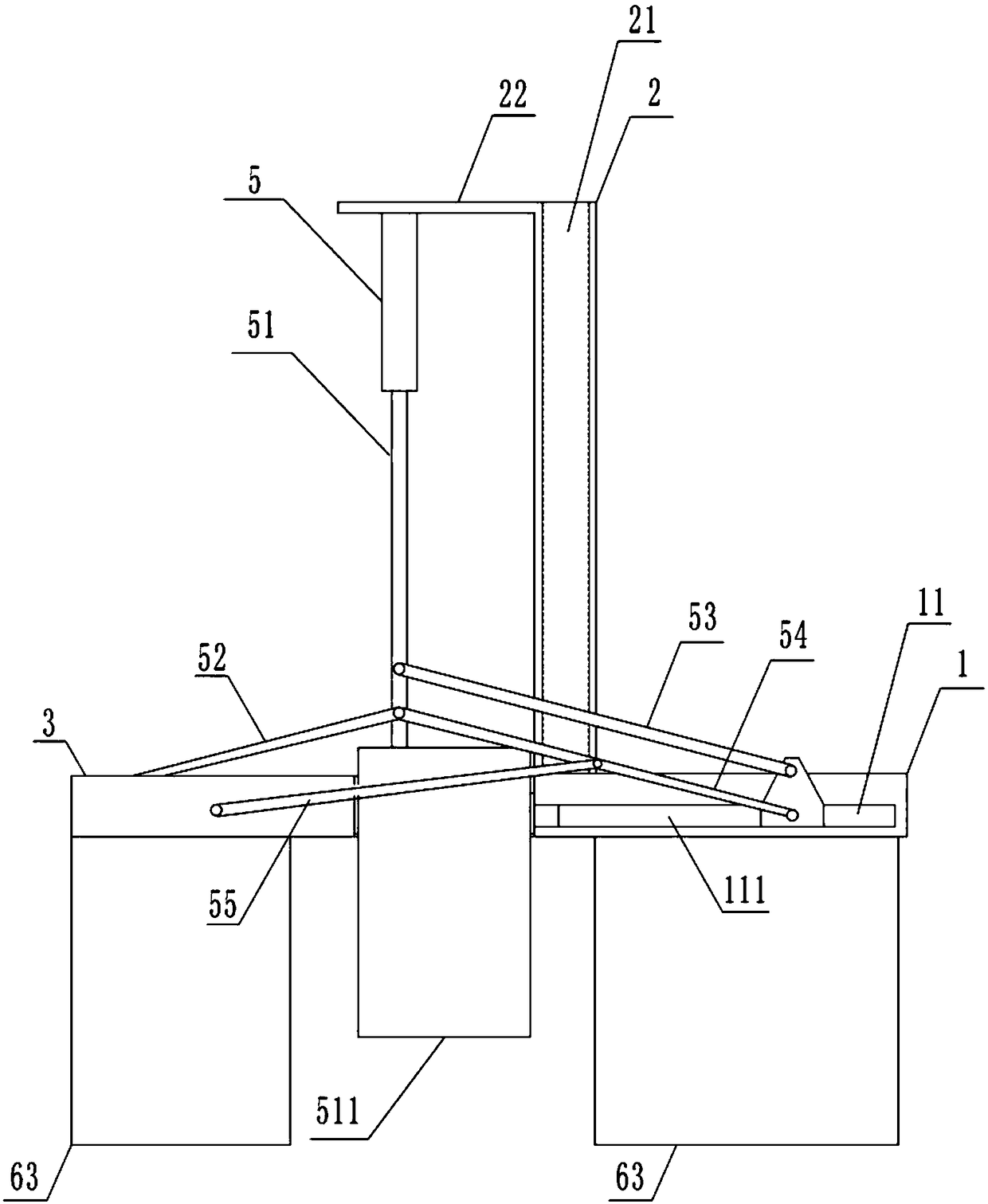

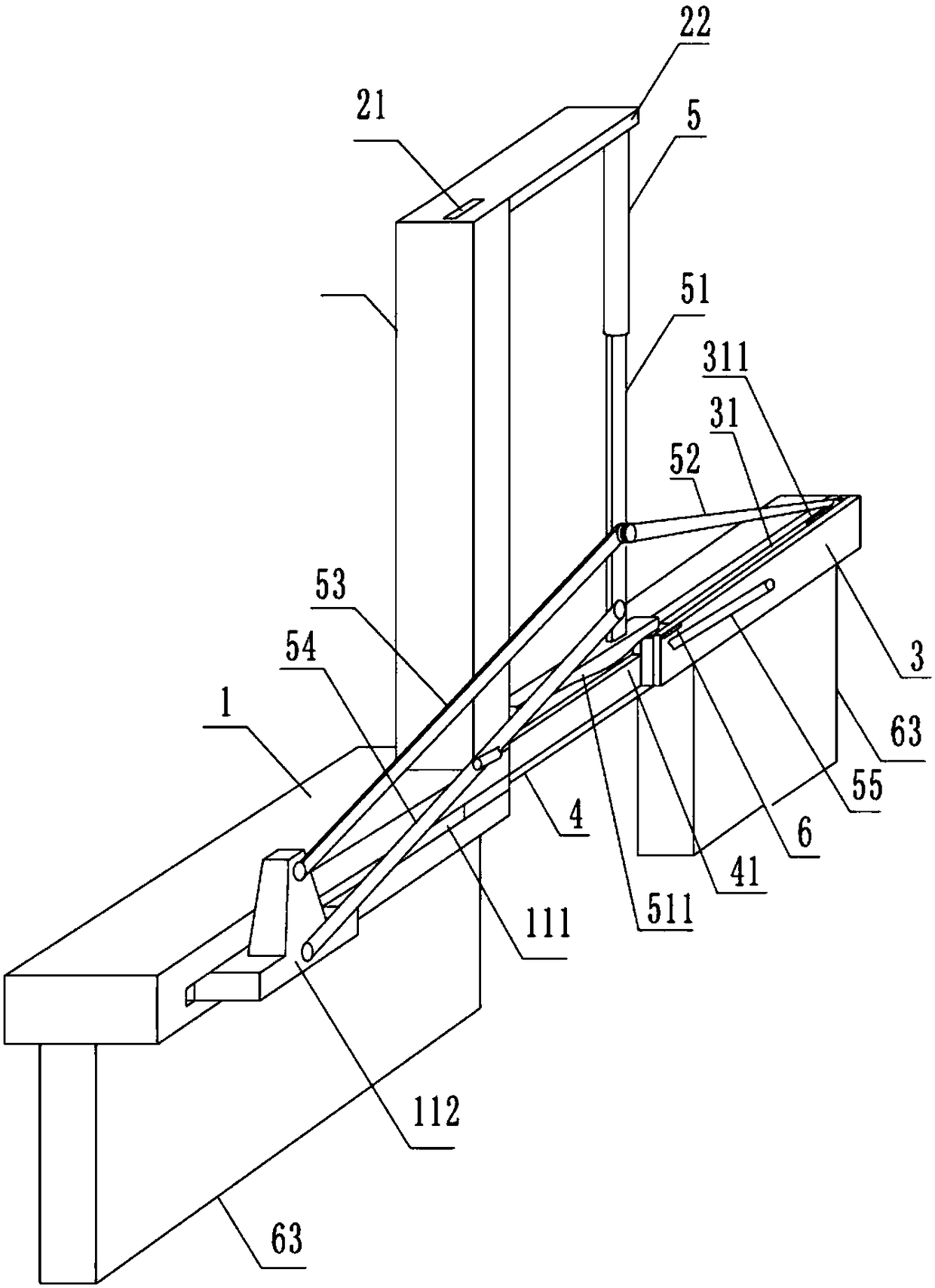

[0029] The reference signs in the drawings of the description include: horizontal platform 1, chute 11, pushing block 111, fixed platform 112, vertical platform 2, battery placement chamber 21, support plate 22, tail piece placement part 3, strip placement slot 31. Push block 311, channel plate 4, positioning plate 41, hydraulic cylinder 5, push rod 51, baffle plate 511, first connecting rod 52, second connecting rod 53, third connecting rod 54, fourth connecting rod 55, Top plate 6, strip groove 61, convex strip 62, support platform 63, battery 7, tail piece 71, glue 72.

[0030] The embodiment is basically as attached figure 1 , figure 2 , image 3 with Figure 4 As shown, the specific implementation process is as follows:

[0031] A battery tail sticking device, such as figure 2 with image 3 , including a pasting station, a tail piece placement part 3 and a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com