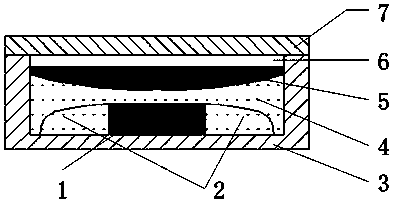

Yellow-light LED packaging structure and packaging method

A technology of LED packaging and LED chips, which is applied in the direction of electric light sources, lighting devices, and components of lighting devices, can solve the problems of low luminous efficiency of yellow LEDs, solve the problems of water and oxygen isolation and heat insulation, reduce costs, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

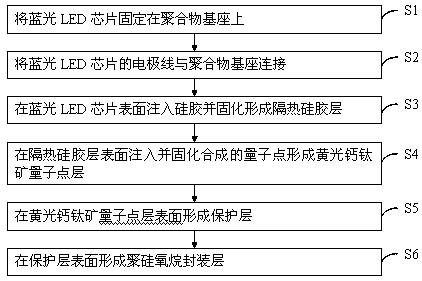

Method used

Image

Examples

Embodiment 1

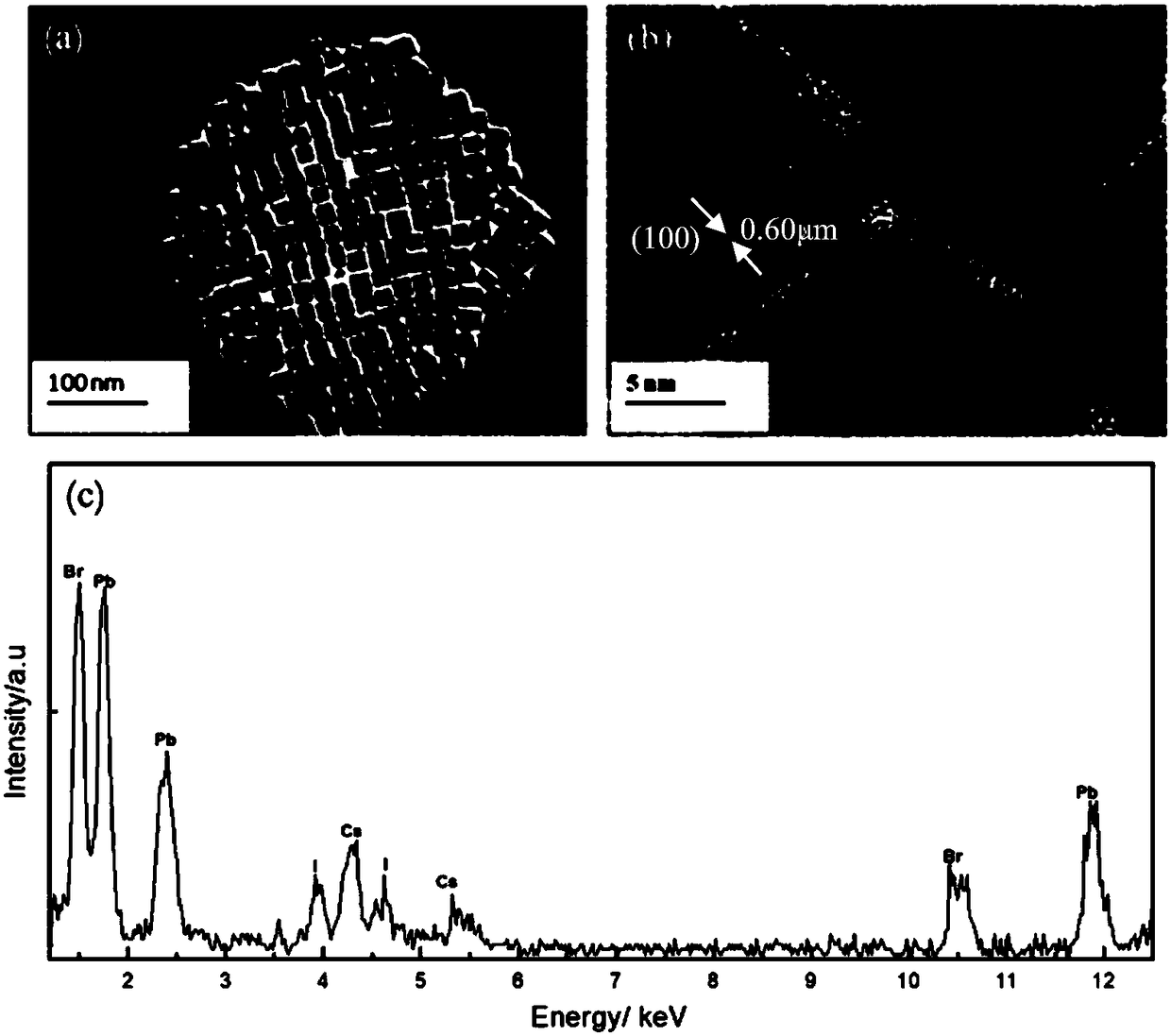

[0049] First, mix the two-component heat-insulating silica gel evenly according to the mass ratio of 1:1, then place it in a vacuum drying oven at room temperature to defoam until there are no bubbles, and then evenly inject it into the polymer base with the blue LED chip fixed until the chip is submerged 1mm; then cured at constant temperature in a vacuum drying oven, pre-cured at 60°C for 1 hour, and continued to cure at 160°C for 2 hours. Under the action of surface tension, the silica gel naturally forms a bowl structure. Then quantum dots are synthesized, using cesium stearate, oleic acid, oleylamine, PbI 2 and PbBr 2 Synthesis of yellow light perovskite quantum dots CsPb(Br x I 1-x ) 3 , where x=0.60, such as image 3 As shown, among them, image 3 (a) is the TEM image of the yellow light perovskite quantum dots, image 3 (b) is an enlarged view of the yellow light perovskite quantum dot transmission electron microscope, image 3 (c) is the energy dispersive x-ray...

Embodiment 2

[0051] First, mix the two-component heat-insulating silica gel evenly according to the mass ratio of 1:1, then place it in a vacuum drying oven at room temperature to defoam until there are no bubbles, and then evenly inject it into the polymer base with the blue LED chip fixed until the chip is submerged 1mm; then cured at constant temperature in a vacuum drying oven, pre-cured at 60°C for 1 hour, and continued to cure at 140°C for 3 hours. Under the action of surface tension, the silica gel naturally forms a bowl structure. Then quantum dots are synthesized, using cesium stearate, oleic acid, oleylamine, PbI 2 and PbBr 2 Synthesis of yellow light perovskite quantum dots CsPb(Br x I 1-x ) 3 , where x=0.65, the synthesized quantum dots were centrifuged, using cyclohexane as the solvent, the solid-liquid ratio was 1:1 (ml / mg), injected into the surface of the cured silica gel after ultrasonic dispersion for 10s, and then vacuum Stand in a dry box at 35°C for 1 hour. After ...

Embodiment 3

[0053] First, mix the two-component heat-insulating silica gel evenly according to the mass ratio of 1:1, then place it in a vacuum drying oven at room temperature to defoam until there are no bubbles, and then evenly inject it into the polymer base with the blue LED chip fixed until the chip is submerged 1mm; then cured at constant temperature in a vacuum drying oven, pre-cured at 60°C for 1 hour, and continued to cure at 140°C for 3 hours. Under the action of surface tension, the silica gel naturally forms a bowl structure. Then quantum dots are synthesized, using cesium stearate, oleic acid, oleylamine, PbI 2 and PbBr 2 Synthesis of yellow light perovskite quantum dots CsPb(Br x I 1-x ) 3 , where x=0.62, the synthesized quantum dots were centrifuged, using cyclohexane as the solvent, the solid-to-liquid ratio was 1:2 (ml / mg), injected into the surface of the cured silica gel after ultrasonic dispersion for 10s, and then vacuum Stand in a dry box at 30° C. for 1 hour. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com