Gas phase shielding steering cleaning and plug-removing technology for oil field

A clean solution, gas-phase technology, applied in the direction of cleaning equipment, wellbore/well components, drilling composition, etc., can solve the problems of reducing the efficiency of temporary plugging, reducing the effect of plugging removal, and the difficulty of dissolving temporary plugging agents, etc., to achieve Expand the unblocking area, improve the effect of measures, and strengthen the effect of blocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

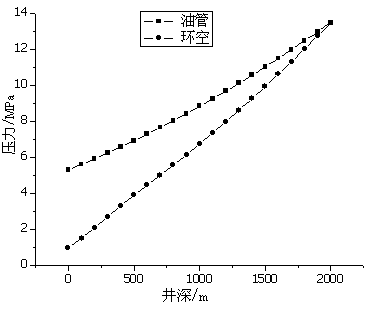

[0022] The invention provides a gas-phase shielding steering cleaning and plugging removal process for oil fields, which includes the following steps:

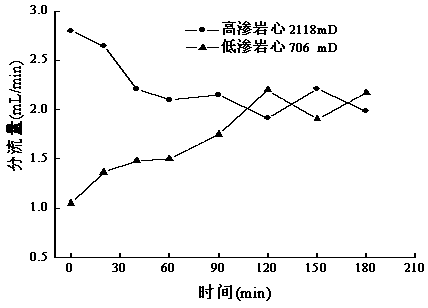

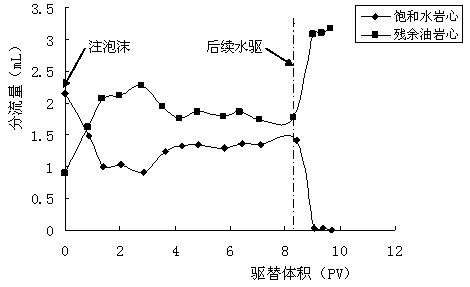

[0023] (1) Pre-construction treatment is carried out at the blocked part of the formation, and pre-shielding diverting agent is injected;

[0024] (2) After all the pre-shielding steering agent has flowed in, inject the rear main body liquid;

[0025] (3) Shut in the well for 1 hour and discharge the residual liquid;

[0026] Measured by weight percentage, the composition of the pre-screening diverting agent: non-ionic surfactant: 5.0%, stabilizer: 3.0%, miscible regulator: 3.0%, gas generator: 20.0%, miscible enhancer: 3.0% , liquid phase fluid: 66.0%; the composition of the post-main liquid: 8% to 16% of inorganic monobasic acid, 3% to 6% of inorganic dibasic acid, 3% to 6% of organic monobasic acid, and 3% of organic dibasic acid ~6%, organic protective agent 1.0%~3.0%, organic stabilizer 2.0%~3%, inorganic stabilizer 1.0...

Embodiment 2

[0032] Well XX is an oil production well in X Oilfield, producing Chang 6 1 1 layer, length 6 1 1 The thickness of the reservoir oil layer is 29.m, and the degree of injection is 42.2%. The dynamics of this well in x years and x months have become worse, and the water cut has suddenly increased by 84.2%. The above-mentioned gas-phase shielding and switching to cleaning and plugging removal technology is adopted. After a period of time, the statistical effect is: After measures Liquid volume 6.14 m 3 , the oil production was 3.2t, and the water cut decreased by 95.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com