Method for constructing or reconstructing assembled platform and special prefabricated module group

A modular and prefabricated technology, applied in the field of construction or renovation of railway station platforms, to achieve the effect of shortening the construction period, easy installation and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

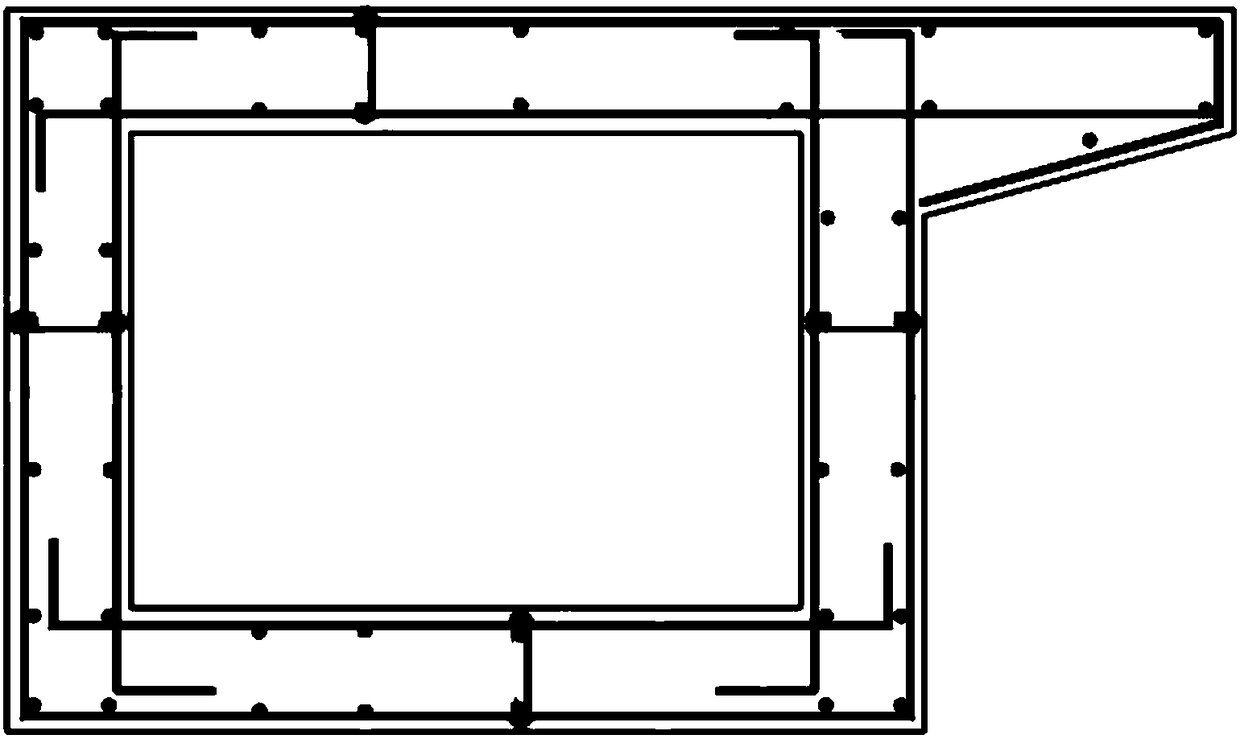

[0044] like Figure 1-4 As shown, a prefabricated module group for building or transforming a platform is composed of prefabricated module I1 and prefabricated module II2. A support edge 11 is provided on the top of the right side of the structure.

[0045] The external dimensions of the cuboid structure are length×width×height: 1200mm×1200mm×700mm, the width of the supporting edge 11 is 300mm, the length is 1200mm, and the height is 180mm; ).

[0046] The prefabricated module Ⅰ1 and prefabricated module Ⅱ2 are reinforced concrete structures, and the reinforcement adopts the first-grade steel bar with a diameter of 6mm and the third-grade steel bar with a diameter of 8mm. The reinforcement diagram is as follows image 3 , 6 shown.

[0047] like Figure 5 As shown, a prefabricated platform adopts the prefabricated module group described in Embodiment 1, and a fine stone concrete cushion 4 is laid on the base layer 10. On the cushion layer 4, the prefabricated module I1 is...

Embodiment 2

[0059] The difference from Example 1 is that the external dimensions of the cuboid structure are length×width×height: 2400mm×2400mm×1500mm, the width of the support edge 11 is 500mm, the length is 2400mm, and the height is 230mm.

Embodiment 3

[0061] A method for building a new platform differs from Embodiment 1 in that: in step ②, it is necessary to perform foundation treatment first, replace and fill with antifreeze sand, pour concrete strip foundations, and then install prefabricated modules.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com