Airtight waterproof method adopting chemical vapor deposition long carbon chain silicone compound

A chemical vapor deposition, long carbon chain silane technology, applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve problems such as failure of air tightness detection, and achieve the effect of improving air tightness quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to enable those skilled in the art to understand the purpose of the present invention, preferred embodiments of the present invention are described in detail as follows.

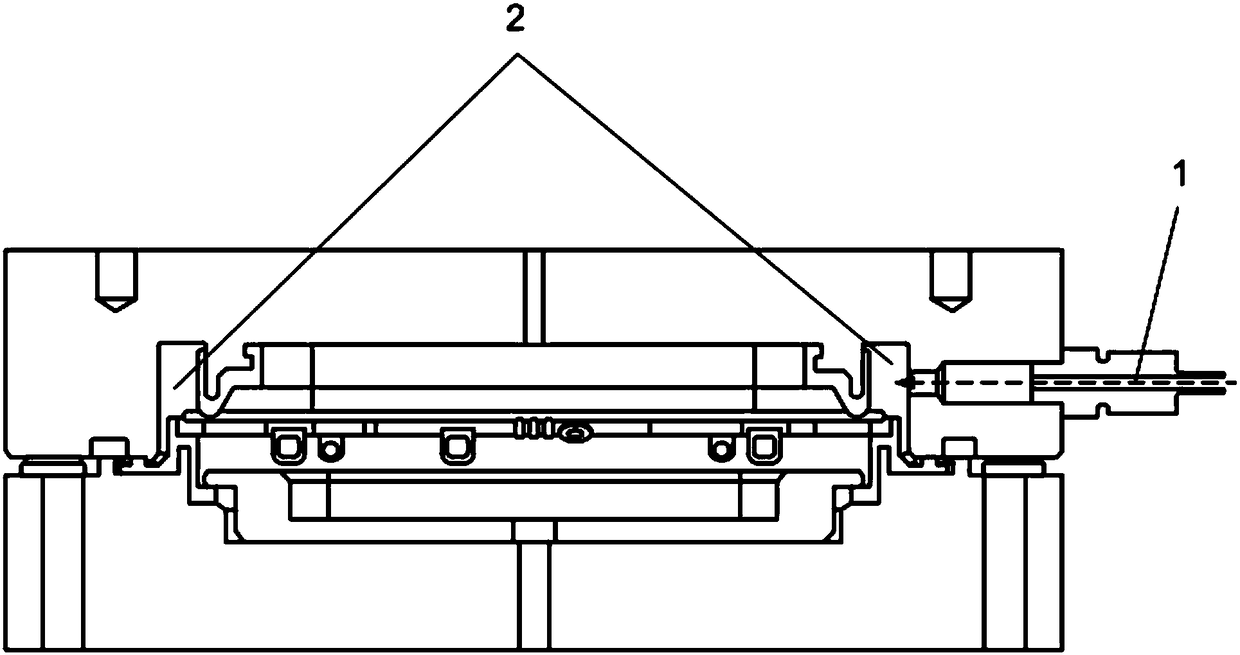

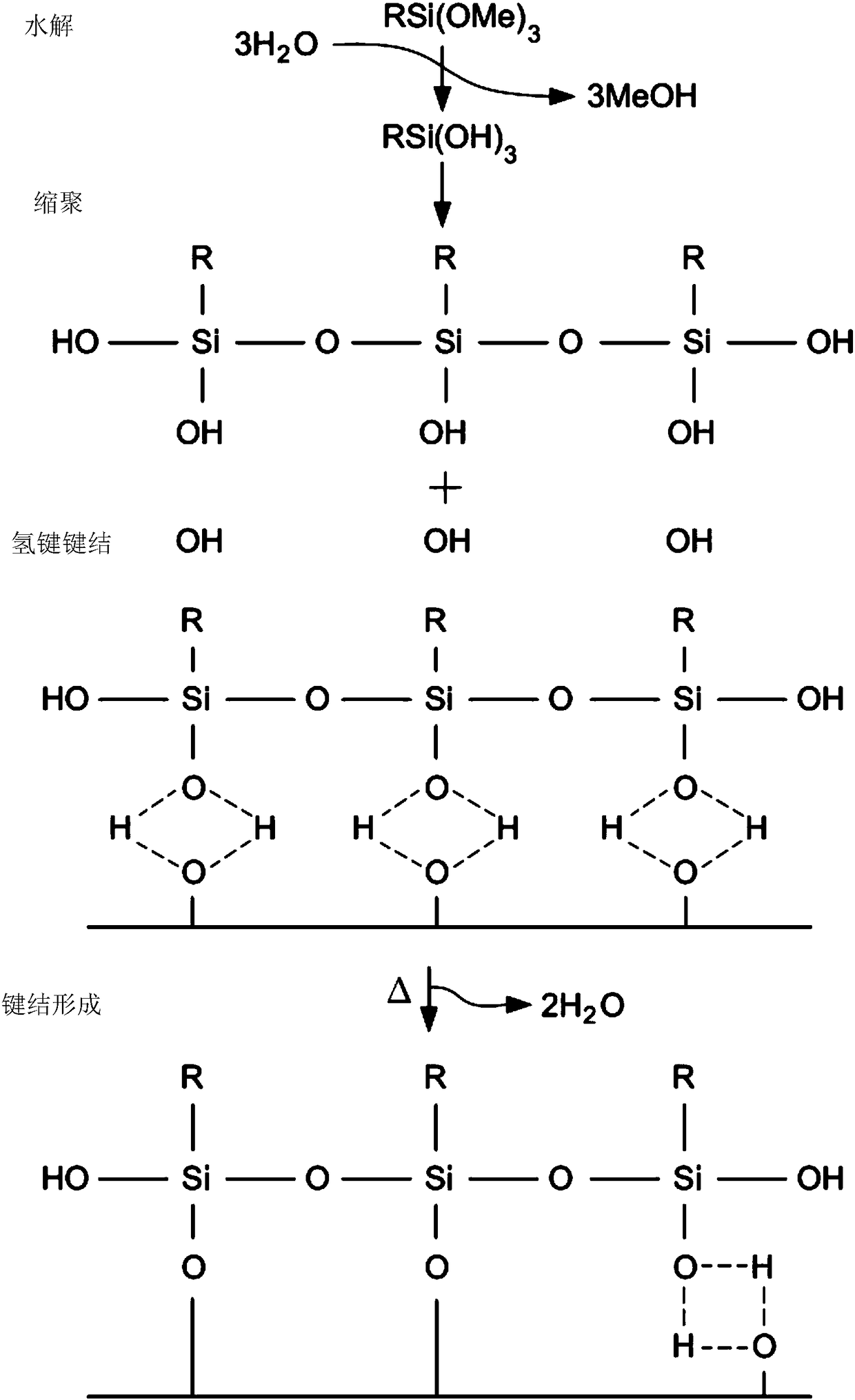

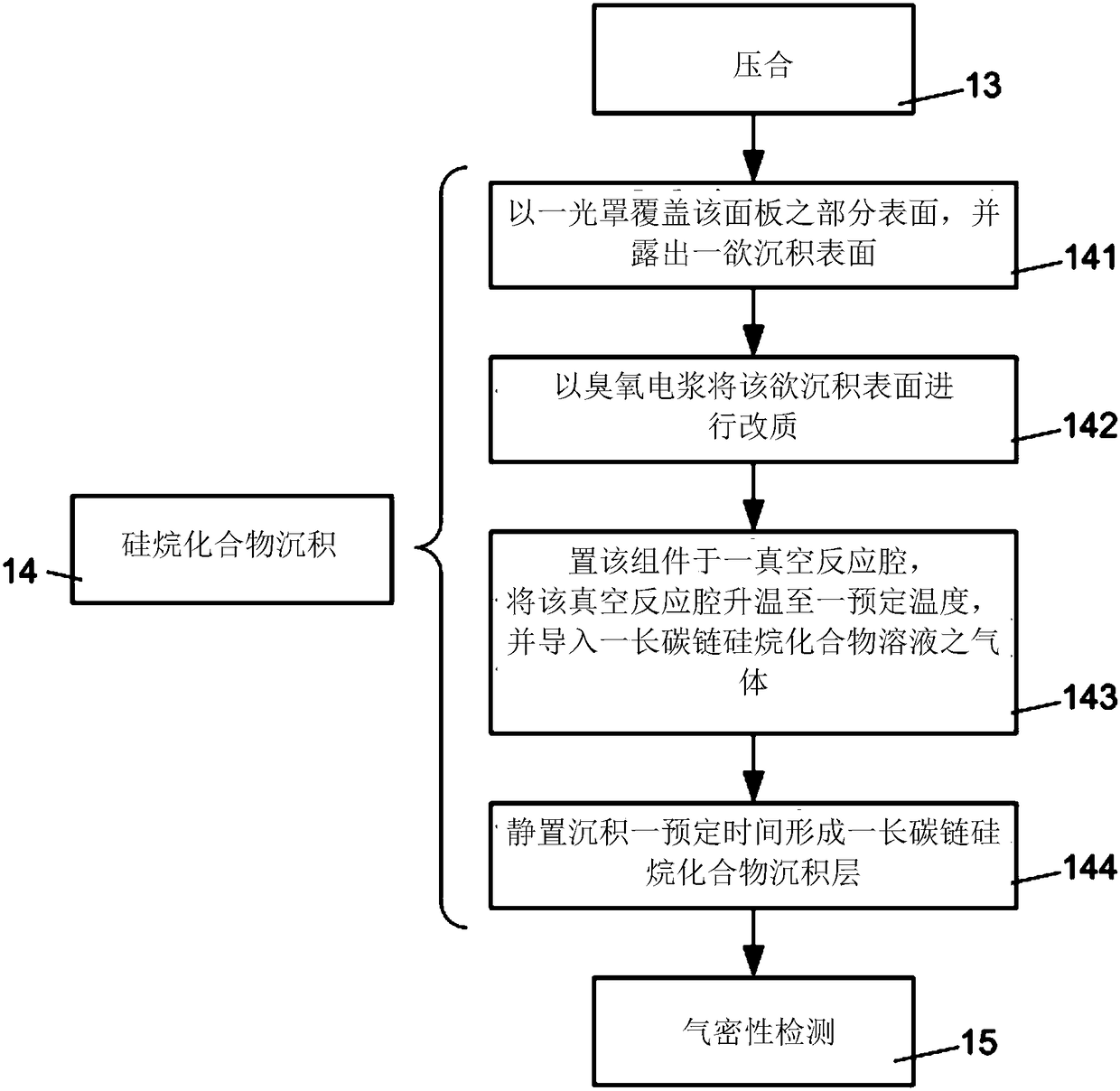

[0039] Please refer to Figure 4 , in one embodiment, the long carbon chain silane compound is deposited on the edge of the connection between a panel 3 and a frame 4 by vacuum chemical vapor deposition. The panel is a glass panel. The panel 3 and the frame body 4 are pressed together first, and the panel 3 and the frame body 4 are bonded with glue 5 to form an assembly. Then part of the panel 3 is covered with a mask 6 to expose the surface to be deposited. Then use ozone plasma 12 to modify the surface to be deposited.

[0040] Put the assembly into a vacuum reaction chamber 11, ensure that there is no other gas in the reaction chamber to interfere with the subsequent reaction, and heat the vacuum reaction chamber to 40° C., and introduce a gas 7 containing a precursor solution of long c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com