Air tightness detection clamp

A technology for testing fixtures and airtightness, which is applied in the direction of using liquid/vacuum to measure liquidtightness and detecting the appearance of fluid at leakage points, etc. It can solve the problem of affecting the airtightness of underwater work clothing, the fixture is easy to fall off or Problems such as collapse and lower product quality, to reduce the possibility of falling off and misjudgment, light weight, and improve the quality of airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

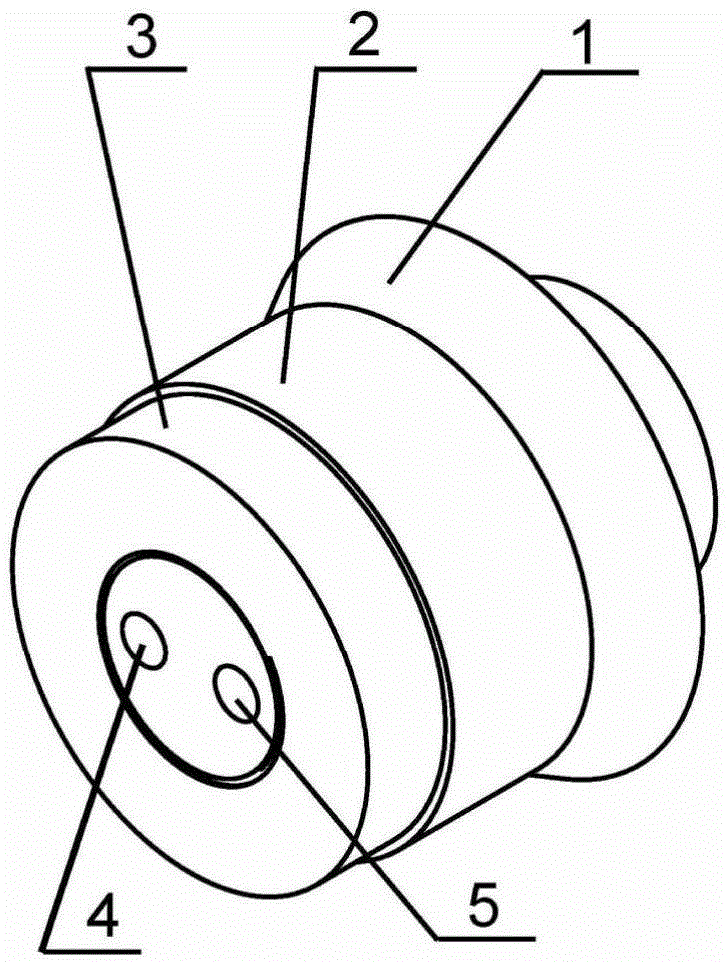

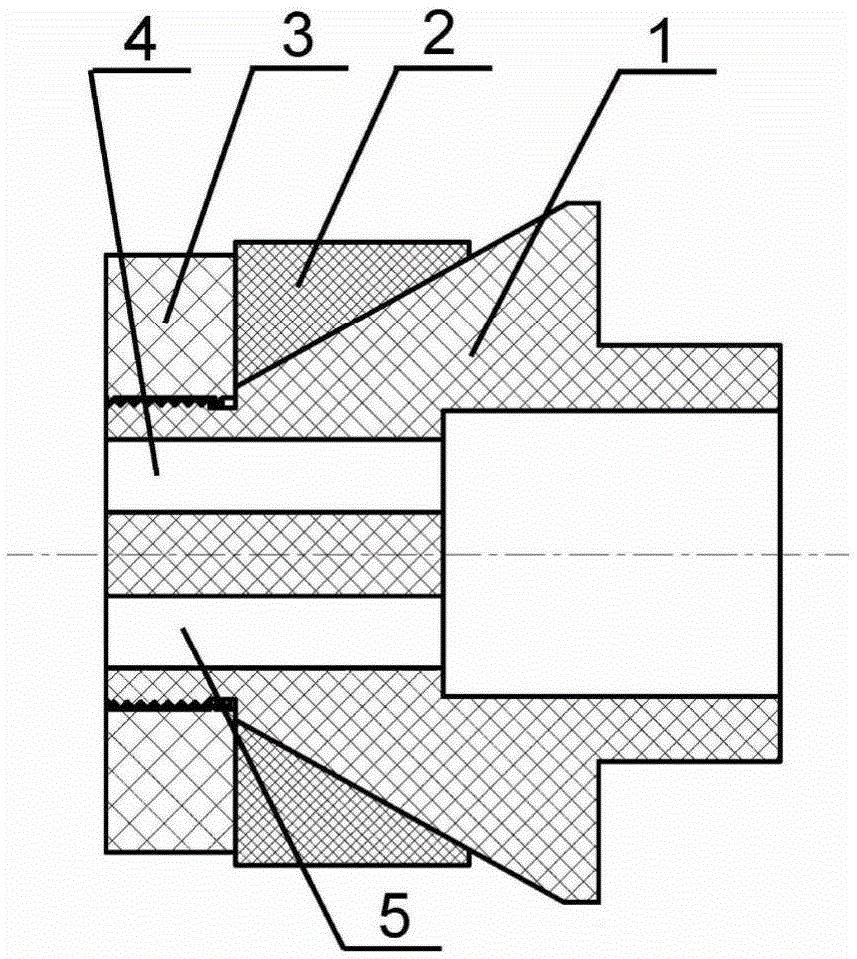

[0020] Such as figure 1 , figure 2 Shown: the present invention comprises: lining taper shaft main body 1, compression taper sleeve 2, and tighten nut 3; The outer tapered surface of the lined cone shaft main body 1 fits; the tightening nut 3 is installed on the lined cone shaft main body 1 by threading in, and the compression taper sleeve 2 is pushed to move axially during the screwing process, so that the compression The inner tapered surface of the taper sleeve 2 and the outer tapered surface of the lined tapered shaft main body 1 are closely matched and locked. The main body 1 of the lined cone shaft is provided with an air inlet 4 and an air outlet 5 , and the air inlet 4 and the air outlet 5 are holes reserved for the air inlet pipe 7 and the air outlet pipe 8 on the air tightness testing device 9 .

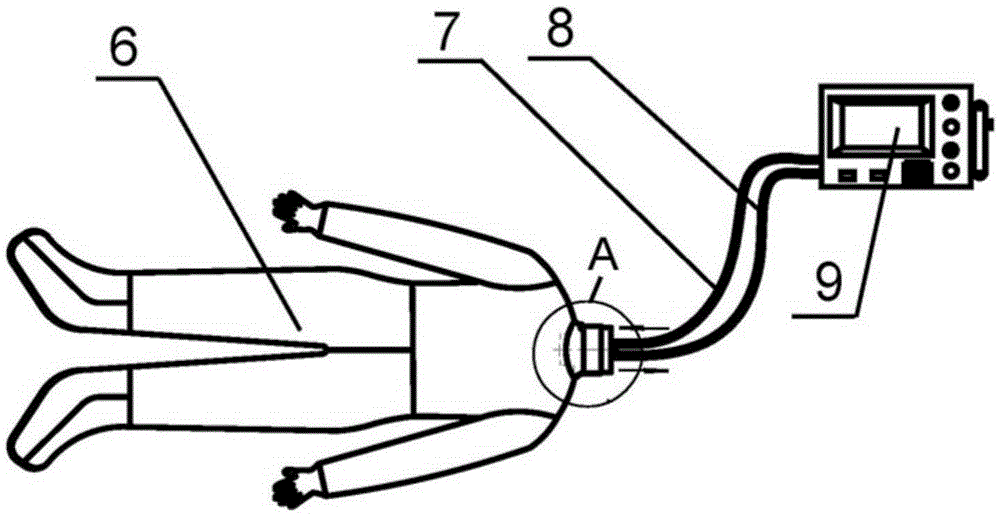

[0021] Such as image 3 , 4 , shown in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com