Mask plate and manufacturing method thereof

A manufacturing method and mask technology, applied in semiconductor/solid-state device manufacturing, ion implantation plating, coating, etc. It can achieve 25μm to 40μm and other problems, achieving the effect of high quality and precision, reducing thickness and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] It can be seen from the background technology that the quality and accuracy of the metal mask cannot well meet the requirements of the process.

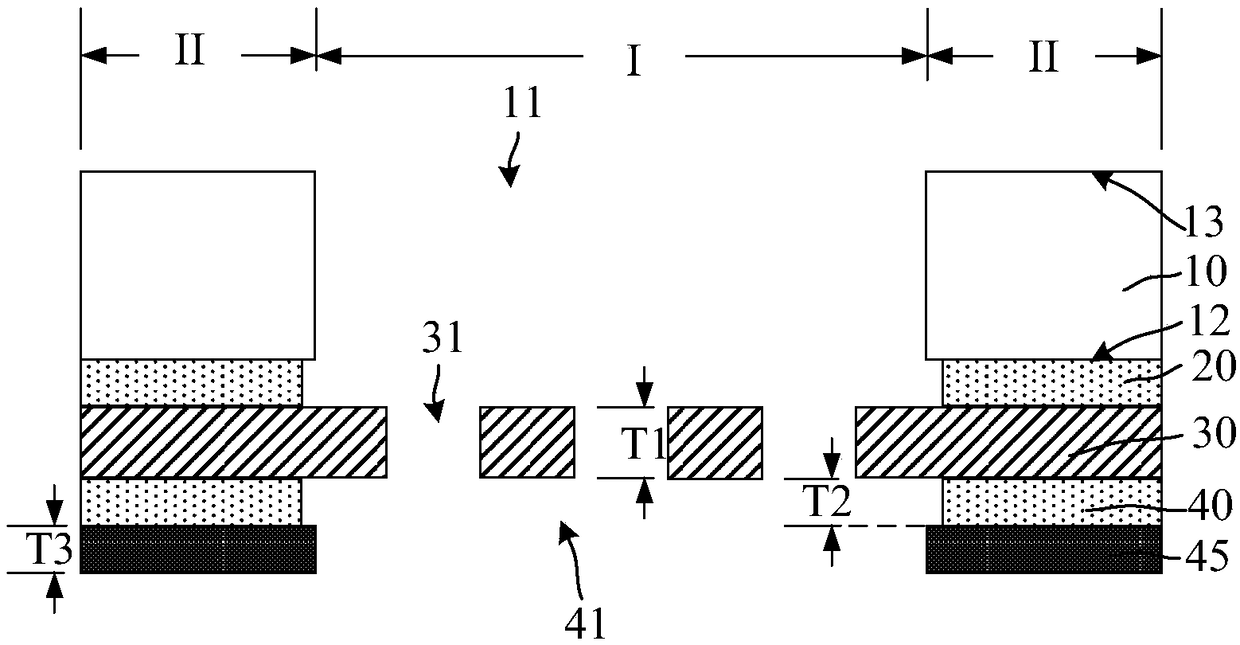

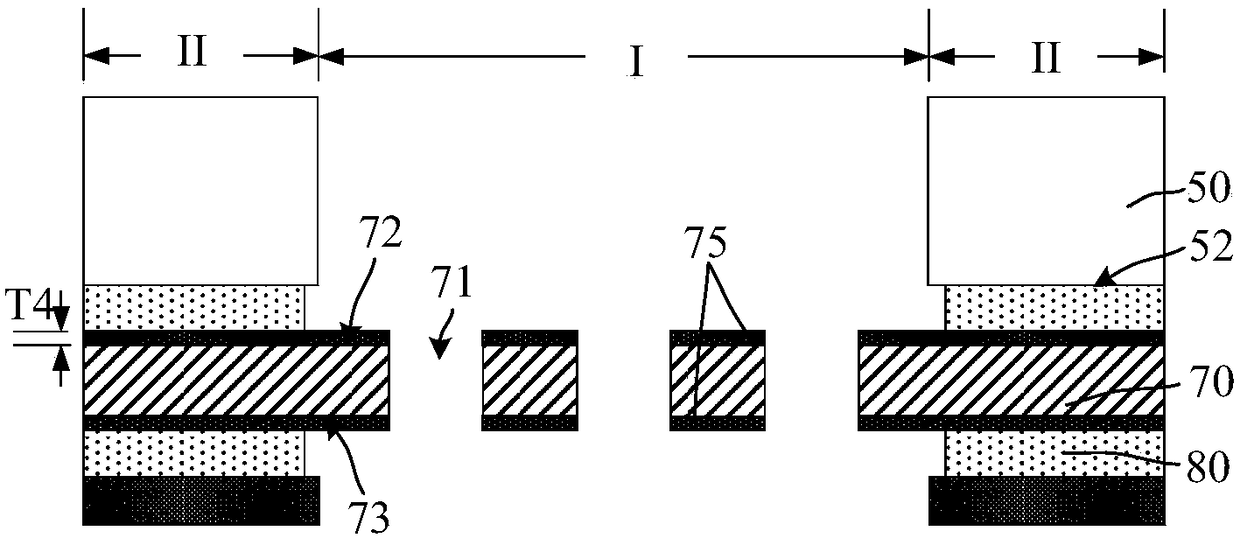

[0018] In order to solve the technical problem, the present invention uses semiconductor processes such as deposition, photolithography and etching to make a mask. Compared with the metal mask made by traditional chemical etching, the semiconductor process can improve the The quality of the mask plate and the accuracy of the through holes are improved, thereby improving the quality and accuracy of the mask plate, which is beneficial to improving the precision of the evaporation process.

[0019] In order to make the above objects, features and advantages of the present invention more comprehensible, specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0020] figure 1 It is a structural schematic diagram of an embodiment of the mask plate of the presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com