Method for preparing coal water slurry by using cracked carbon black containing FCC discharge agent

A technology of unloading agent and coal water slurry, which is applied in the direction of liquid carbon-containing fuel, petroleum industry, fuel, etc., can solve the problems of difficult harmless treatment, poor reaction selectivity, and increased treatment cost, and achieve resource utilization Effects of high-value utilization, lower cracking temperature, and improved combustion characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

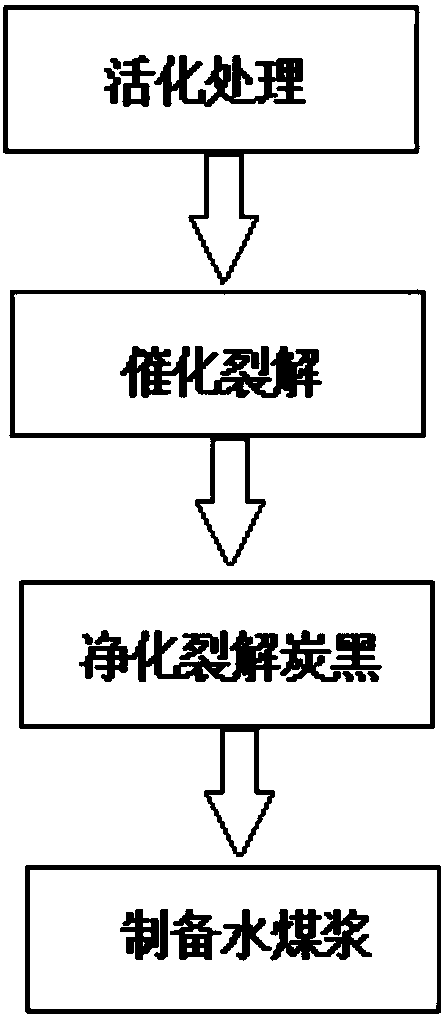

[0021] The specific technological process of the method for preparing coal-water slurry by utilizing cracking carbon black containing FCC unloading agent involved in the present embodiment comprises four steps of activation treatment, catalytic cracking, purification of cracking carbon black and preparation of coal-water slurry:

[0022] (1) Activation treatment: choose one of the following three activation methods:

[0023] 1. Use an all-round planetary ball mill to grind the FCC unloading agent for 5 hours, and grind the particle size of the FCC unloading agent to 10-100 nanometers to improve the activity of the FCC unloading agent;

[0024] 2. Use sulfuric acid with a mass fraction of 10-12% to soak the FCC unloading agent for 3 hours to increase the acidity of the FCC unloading agent to improve the activity of the FCC unloading agent;

[0025] 3. Calcinate the FCC discharge agent at a temperature of 350-370°C for 10 minutes to remove the coke in the FCC discharge agent to ...

Embodiment 2

[0031] The specific technological process of the method for preparing coal-water slurry by utilizing cracking carbon black containing FCC unloading agent involved in the present embodiment comprises four steps of activation treatment, catalytic cracking, purification of cracking carbon black and preparation of coal-water slurry:

[0032] (1) Activation treatment: choose one of the following three activation methods:

[0033] 1. Use an all-round planetary ball mill to grind the FCC unloading agent for 5 hours, and grind the particle size of the FCC unloading agent to 10-100 nanometers to improve the activity of the FCC unloading agent;

[0034] 2. Use sulfuric acid with a mass fraction of 10-12% to soak the FCC unloading agent for 3 hours to increase the acidity of the FCC unloading agent to improve the activity of the FCC unloading agent;

[0035] 3. Calcinate the FCC discharge agent at a temperature of 350-370°C for 10 minutes to remove the coke in the FCC discharge agent to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com